Light intensity-based electronic feedback manual zoom lens

An electronic feedback, zoom lens technology, used in optics, optical components, testing optical performance, etc., can solve the problem of difficult to ensure accurate information about adjusting the lens magnification to the exact position of the current magnification, incorrect reading of the lens magnification value, Low work efficiency and other problems, to achieve the effect of electronic information feedback, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

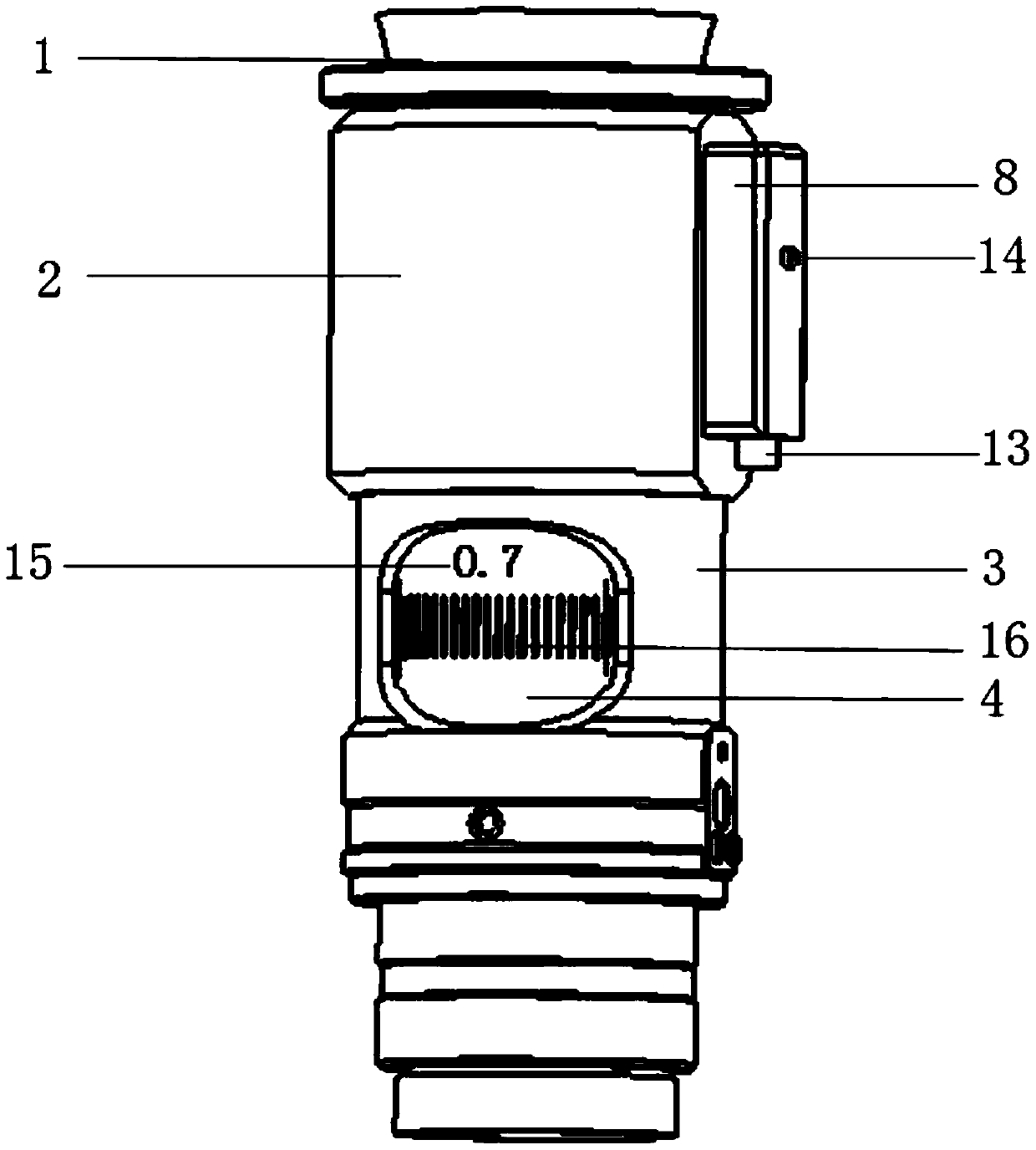

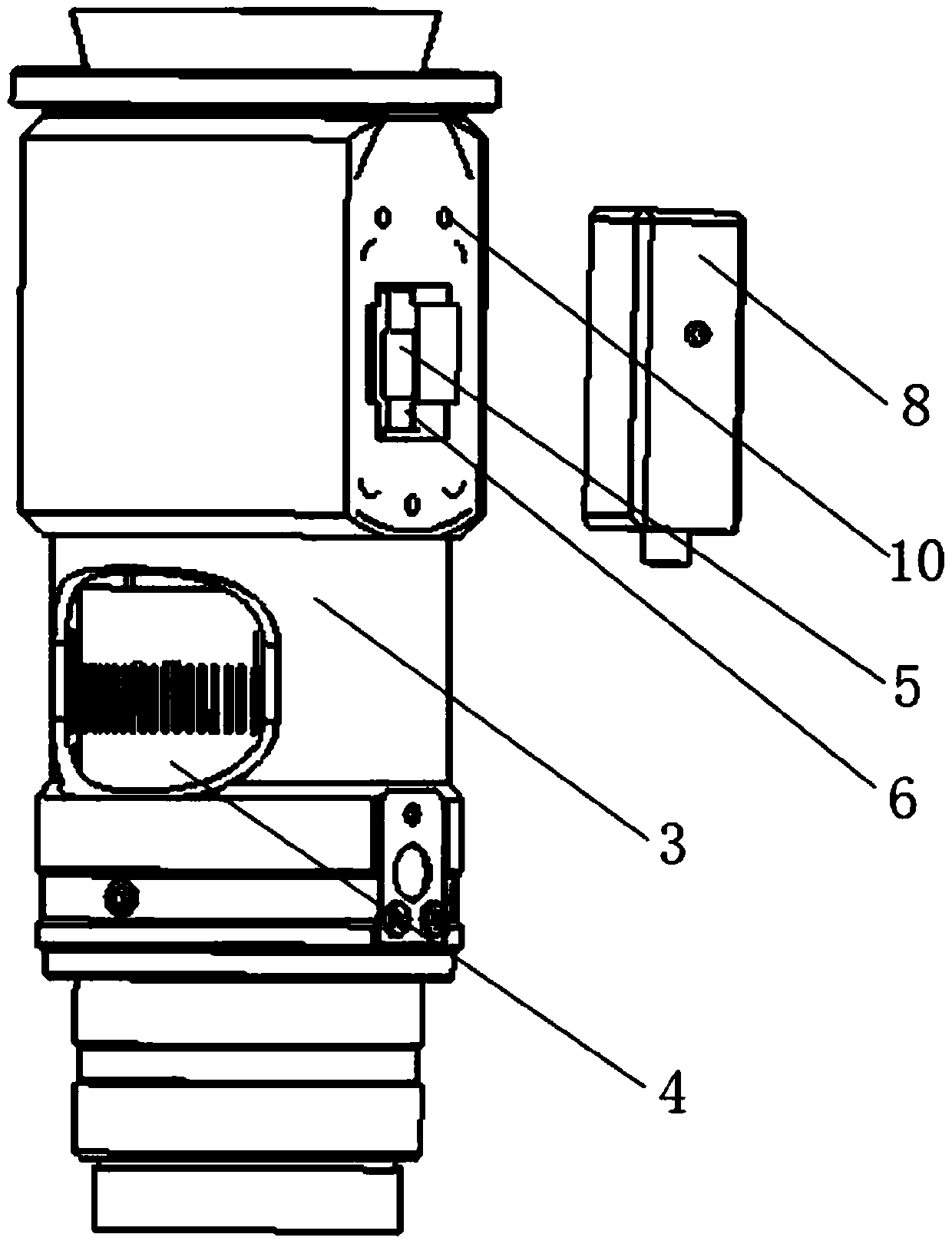

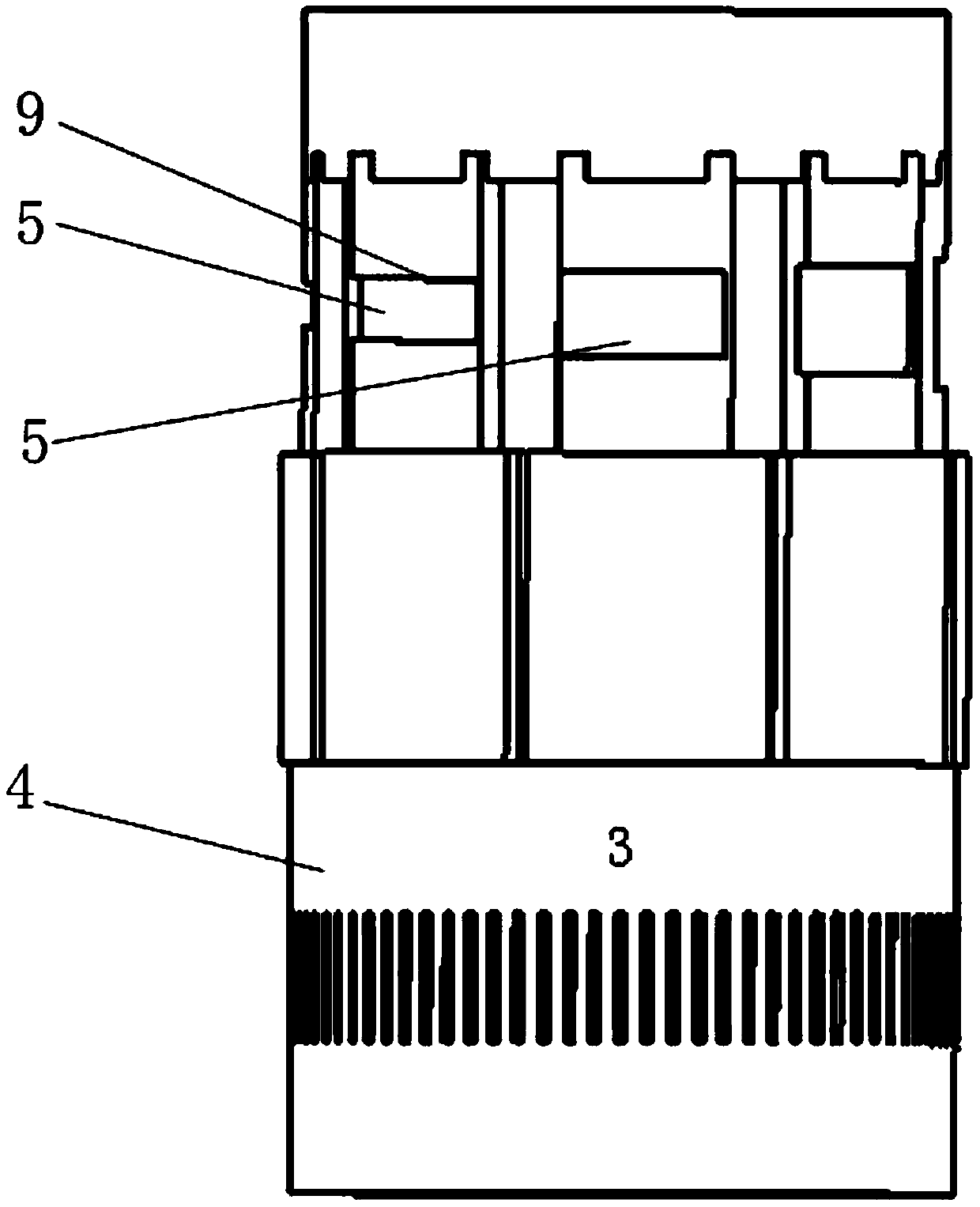

[0020] Such as Figure 1 ~ Figure 4 As shown, a manual zoom lens with electronic feedback based on light intensity of the present invention includes a main body of the manual zoom lens and an electronic feedback device connected to it, and the electronic feedback device is connected to the lower-level equipment (not shown in the figure) , the lower-level equipment uses a single-chip microcomputer; the main body of the manual zoom lens includes a lens adapter 1, an upper lens barrel 2, and a lower lens barrel 3 that are sequentially connected from top to bottom. The rotating shaft sleeve 4 passes through the lower lens barrel 3 and is rotatably connected with the upper lens barrel 2. The upper part of the rotating shaft sleeve 4 is equipped with optical signal reflectors 5 in an annular space. The reflective areas of each optical signal reflector 5 are different, and the corresponding optical signal The upper lens barrel 2 at the reflector 5 is provided with a light opening 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com