Automatic teaching method of glued sensor

A teaching method and sensor technology, which is applied in the direction of instruments, scientific instruments, image enhancement, etc., can solve the problems of increasing the workload of operators, breaking the coating, affecting work efficiency, etc., achieving shortened teaching time, high accuracy, and energy saving The effect of human cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

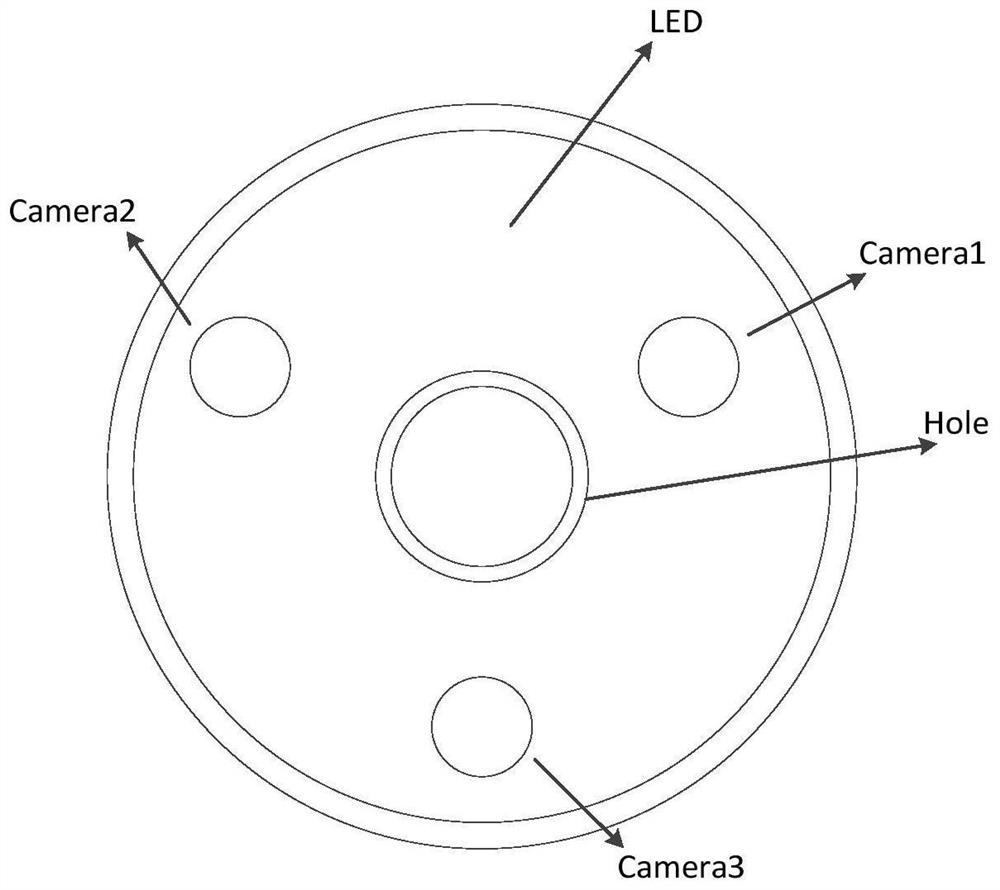

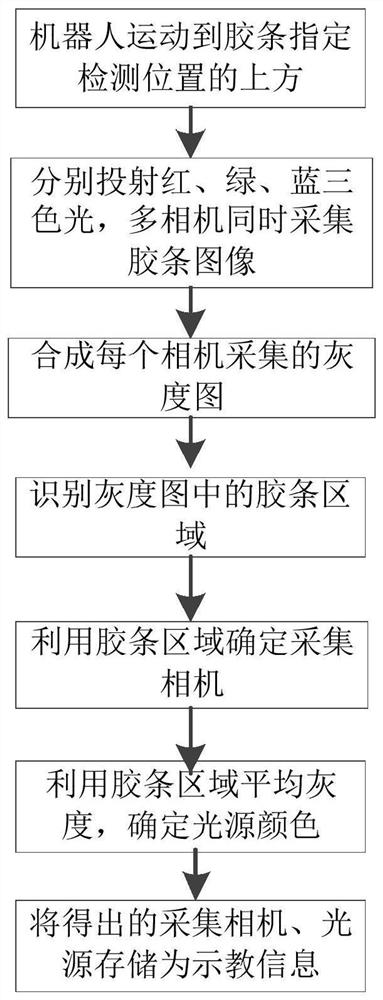

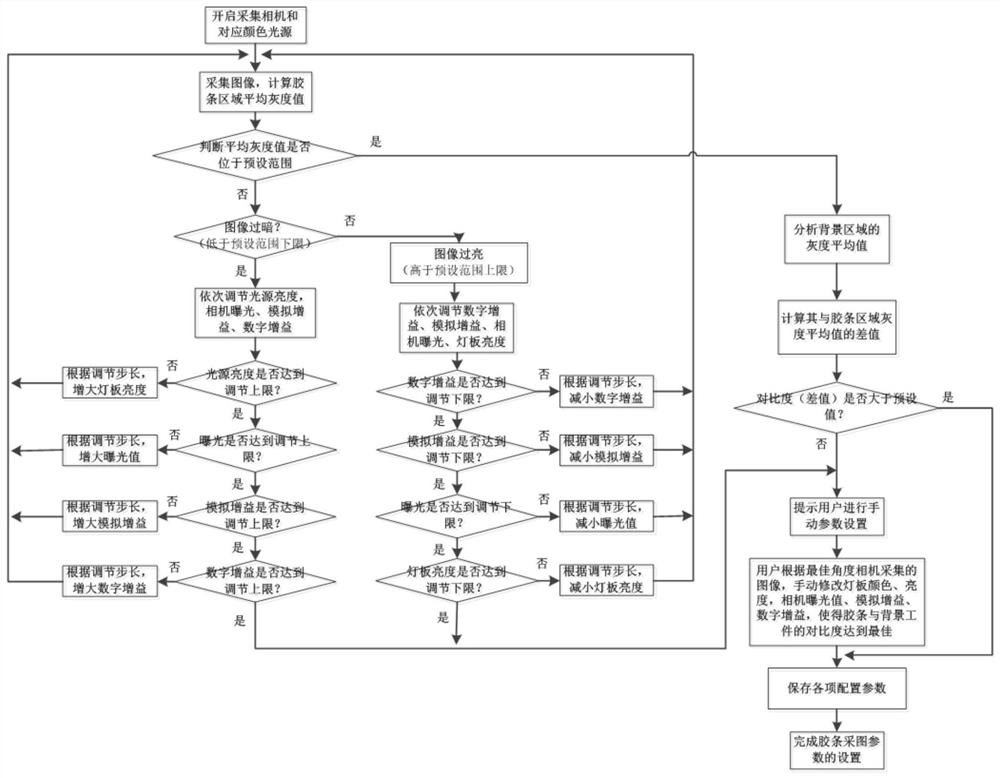

[0037] An automatic teaching method for glued sensors, such as figure 1 As shown, the gluing sensor includes a light source and a plurality of cameras. In this embodiment, there are three cameras. The light source is a three-color LED area array light source, which is set at the front of the sensor, integrated with the main control board, and in the middle of the gluing sensor. Set a through hole, install it on the glue gun, move synchronously with the glue gun, and can detect the glue strip in real time. For the newly added glue strip segment to be tested, the glue coating sensor will perform the following automatic teaching process before the official start of detection. (like figure 2 shown):

[0038] 1) The robot drives the gluing sensor to move above the position of the glue strip to be detected according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com