Reliability test verification system applied to radar microwave product

A test verification and product technology, which is applied in the field of reliability test verification system of radar microwave products, can solve problems such as the failure to fully meet the requirements of product reliability test verification, and achieve the goal of shortening the development cycle, increasing economic benefits, and improving the reliability level. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

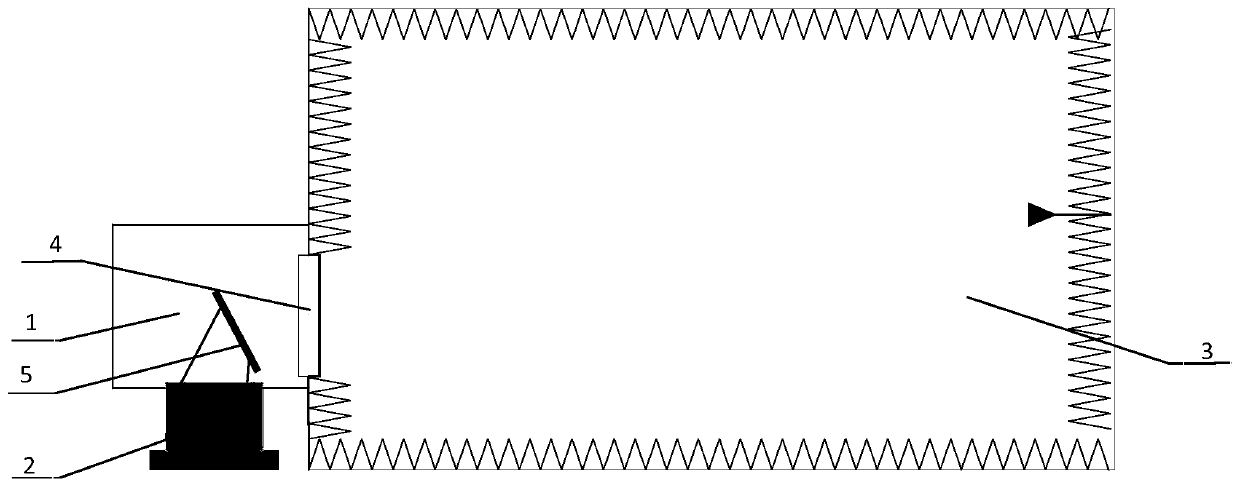

Image

Examples

Embodiment 1

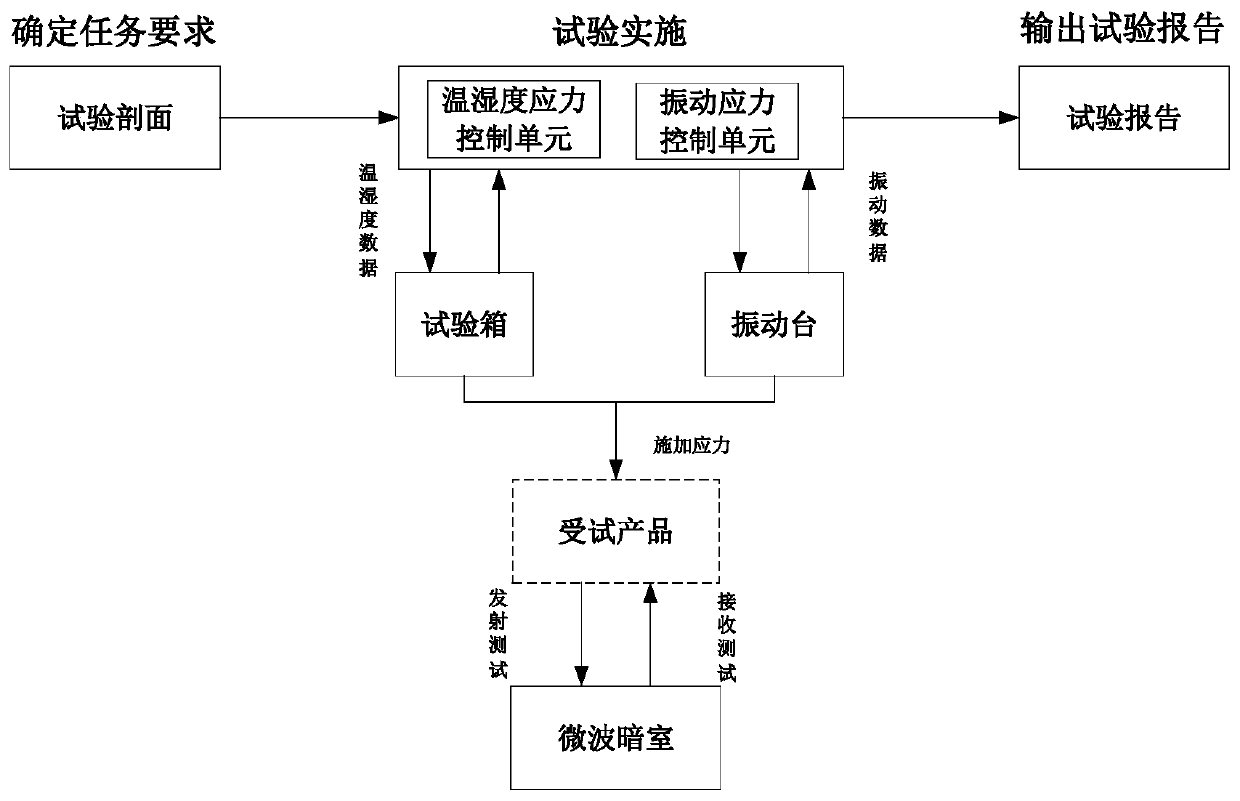

[0033] This embodiment is a process of verifying the reliability of a radar microwave product by using a reliability test verification system for radar microwave products provided by the present invention.

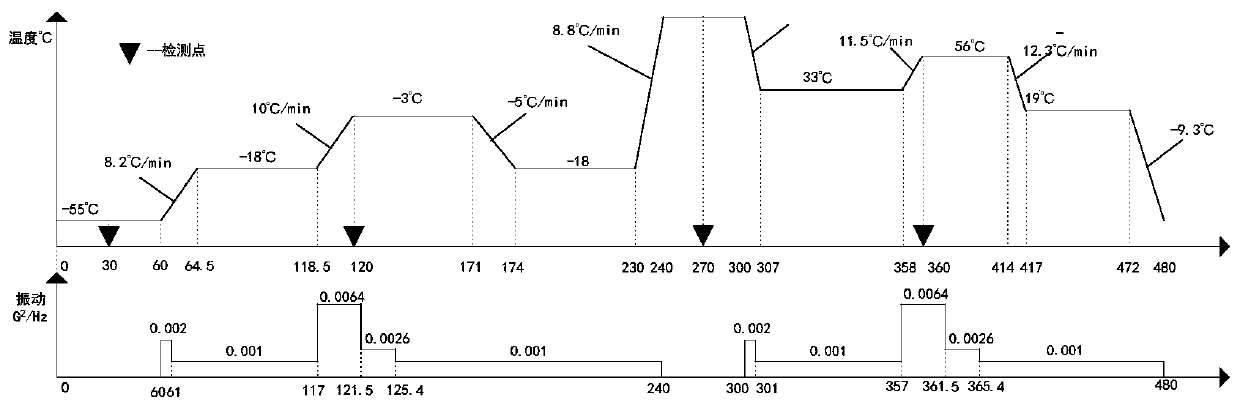

[0034] The cold soak temperature of a radar product is -55°C; the hot soak temperature is +70°C, and the ground working temperature in hot weather is +70°C; the maximum heating rate is 11.5°C / min, and the maximum cooling rate is 12.3°C / min. The duration of one cycle is 8h. Only in the hot days of the cycle, the ground does not work and enter moisture during the working stage, and keep the dew point temperature ≥ 31 ° C. In other stages of the test cycle, do not inject moisture, do not control the humidity, and the air in the test chamber should not be dried . There is one vibration period and four vibration magnitudes in the cold weather and hot weather phases of the entire profile. Vibration stress values, such as acceleration power spectral density, stress application ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com