Jig for welding cable on probe connector

A technology for welding cables and connectors, which is applied in connection, circuits, electrical components, etc., can solve problems such as low production efficiency, low welding accuracy, and difficulty in ensuring product quality, and achieves the effect of compact structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

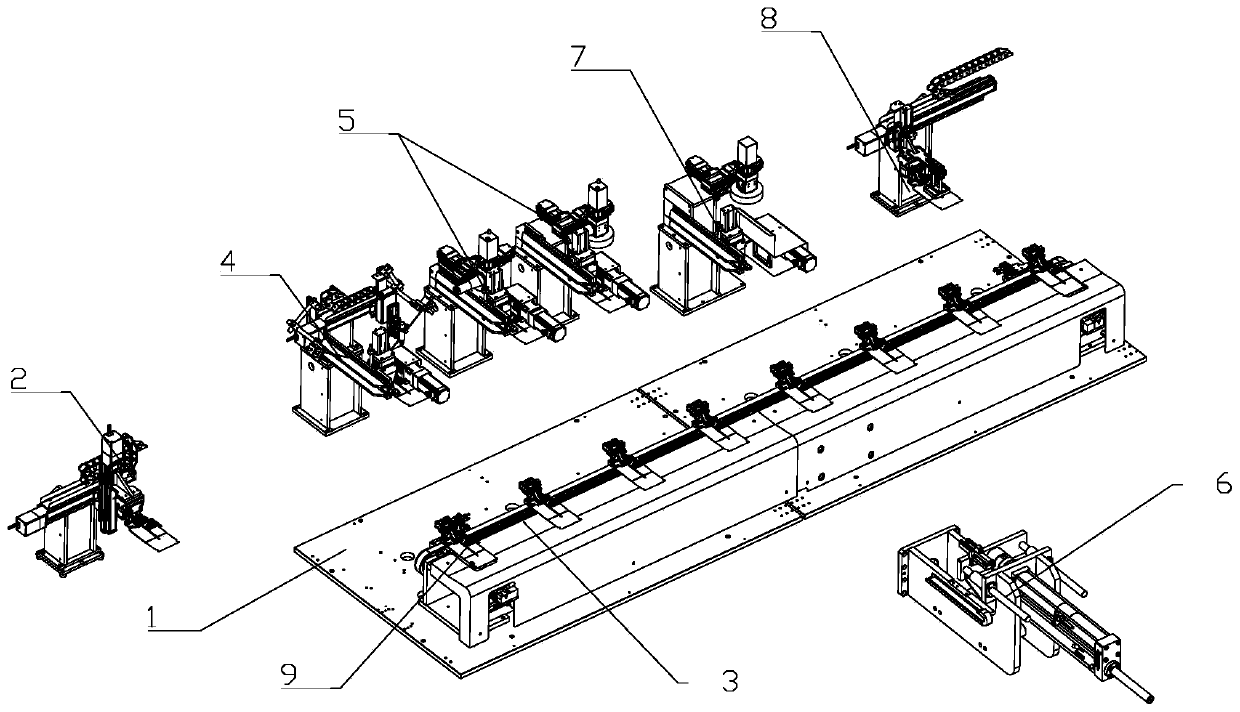

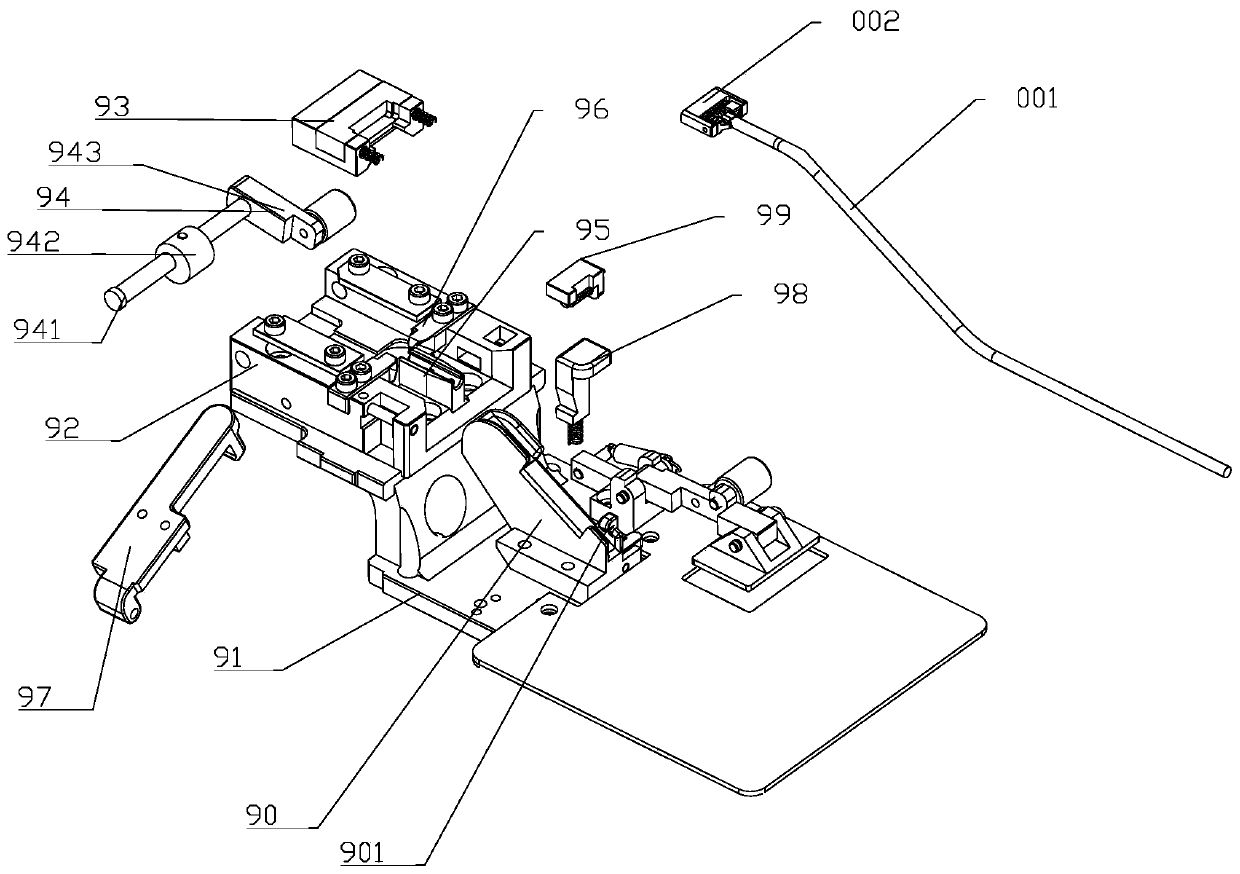

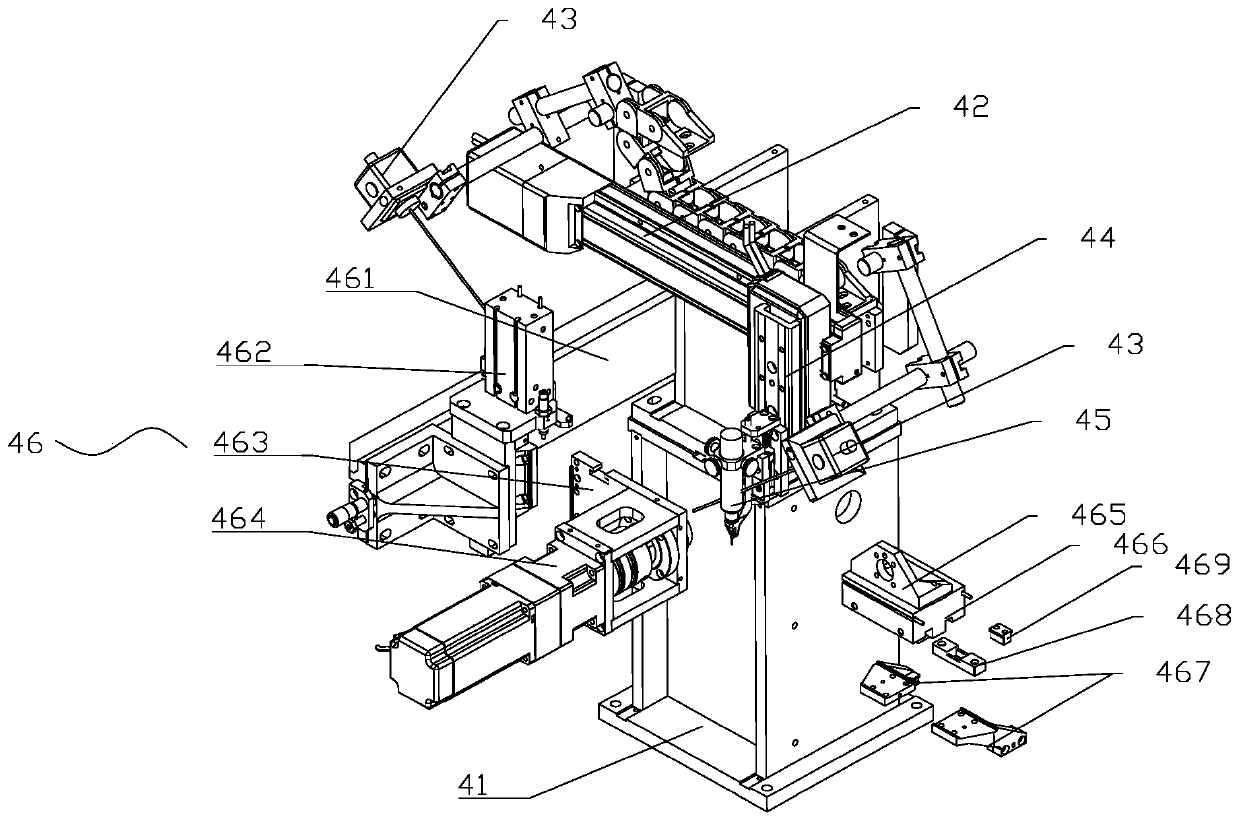

[0020] Such as figure 1 As shown, a cable welding device for a probe connector includes a frame 1 and a loading and conveying device 2 installed on the frame 1, a jig conveying device 3, a tin coating device 4, a laser welding device 5, and a butt welding device 6. The visual inspection device 7 and the unloading and conveying device 8; the feeding and conveying device 2 and the unloading and conveying device 8 are located at both ends of the fixture conveying device 3, and the tin coating device 4 and the laser welding device 5 are arranged on the fixture conveying device 3 The side of the corresponding jig conveying device 3; along the processing direction, the laser welding device 5 is located behind the tin coating device 4, and two sets of laser welding devices 5 are arranged behind the tin coating device 4; the butt welding device 6 is located in the jig conveying device The other side of 3 corresponds to the jig conveying device 3 , and the visual inspection device 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com