Covered stent and manufacturing method thereof

A covered stent and the technology of its manufacturing method are applied in the direction of stents, human body tubular structure devices, blood vessels, etc., and can solve problems such as uneven lumen of covered stents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

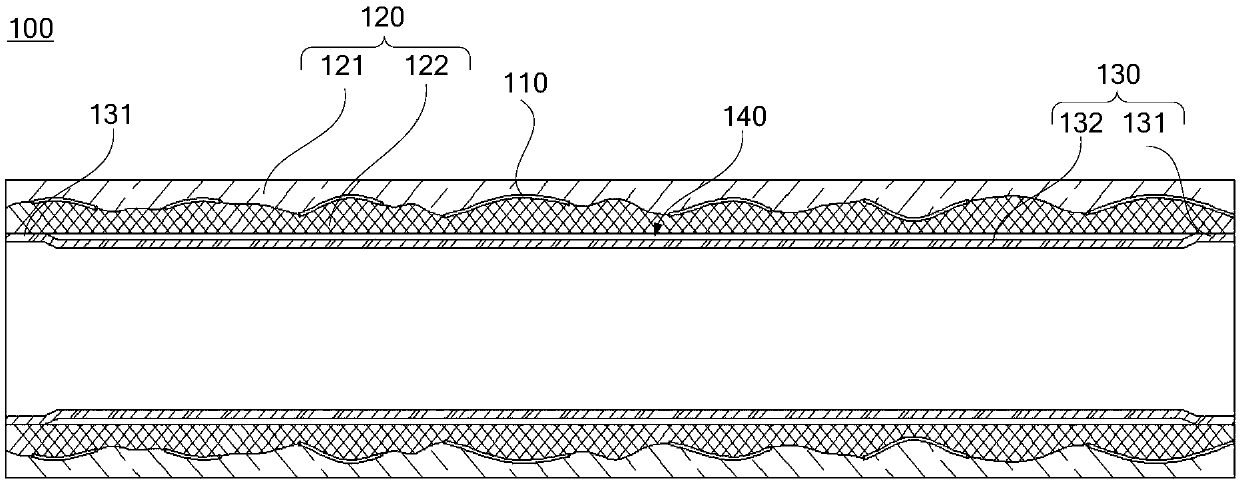

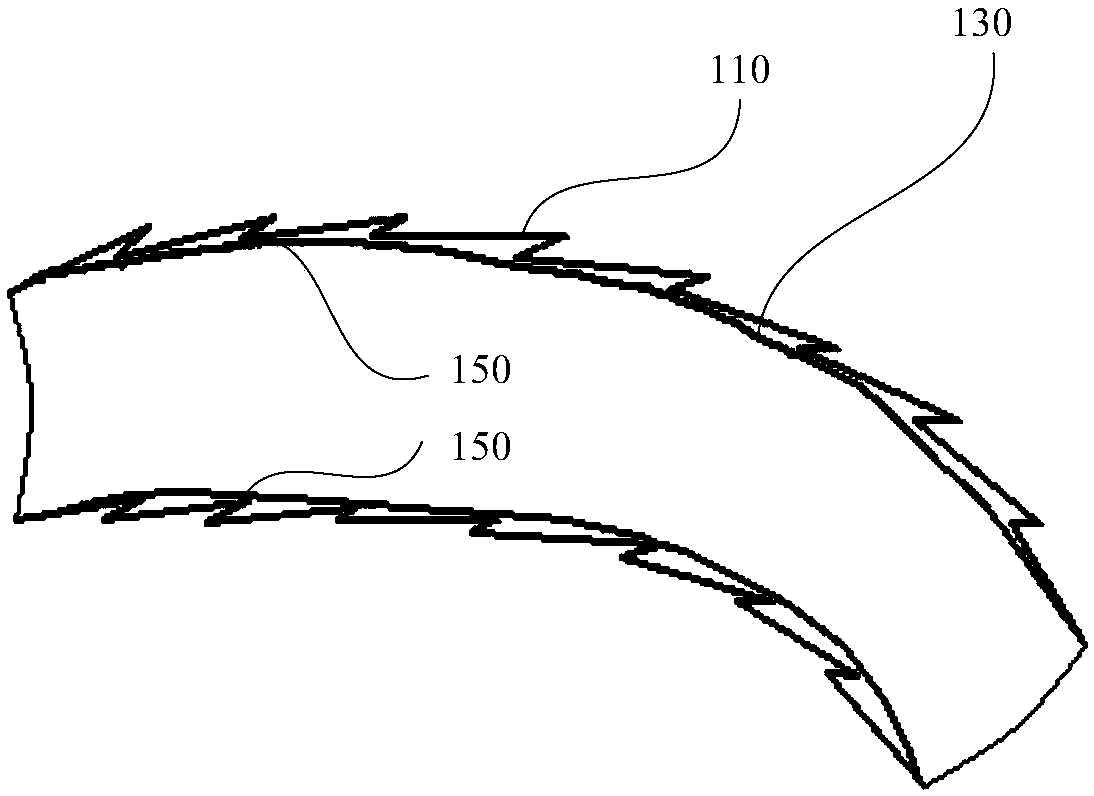

[0031] This embodiment provides a stent graft. figure 1 is a cross-sectional view of the stent graft in Embodiment 1 of the present invention, refer to figure 1 , the stent graft 100 includes a skeleton 110 , a skeleton covering 120 and an inner covering 130 , and the skeleton covering 120 includes an outer covering 121 and a middle covering 122 . The outer coating 121 is arranged on the entire outer peripheral surface of the skeleton 110, the middle coating 122 is arranged on the entire inner peripheral surface of the skeleton 110, and the outer coating 121, the middle layer The covering film 122 and the frame 110 are bonded together in pairs. The inner coating 130 is disposed in the lumen of the stent graft 100 , specifically, the inner coating 130 is disposed on the entire inner wall of the middle coating 122 . The inner coating 130 includes N sections of adhesive section 131 and M sections of separation section 132. In this embodiment, N=2, M=N-1, and both ends of the in...

Embodiment 2

[0045] This embodiment provides a stent graft. The difference between the stent-graft in this embodiment and the stent-graft in Embodiment 1 is that the number of bonding sections in this embodiment is N≥3. The plurality of separation sections and the middle layer coating form a plurality of hollow layers, and the plurality of hollow layers are arranged alternately along the axial direction of the frame.

[0046] Figure 5 It is a cross-sectional view of the stent graft in Example 2 of the present invention, refer to Figure 5 , the plurality of bonding segments 131 of the inner layer coating 130 are respectively bonded together with the middle layer coating 122, and the plurality of separation segments 132 and the middle layer coating 122 form a plurality of hollow layers 140, And a plurality of the hollow layers 140 are arranged alternately along the axial direction of the framework 110 .

[0047] Since the inner layer coating 130 is relatively soft and cannot be bent and...

Embodiment 3

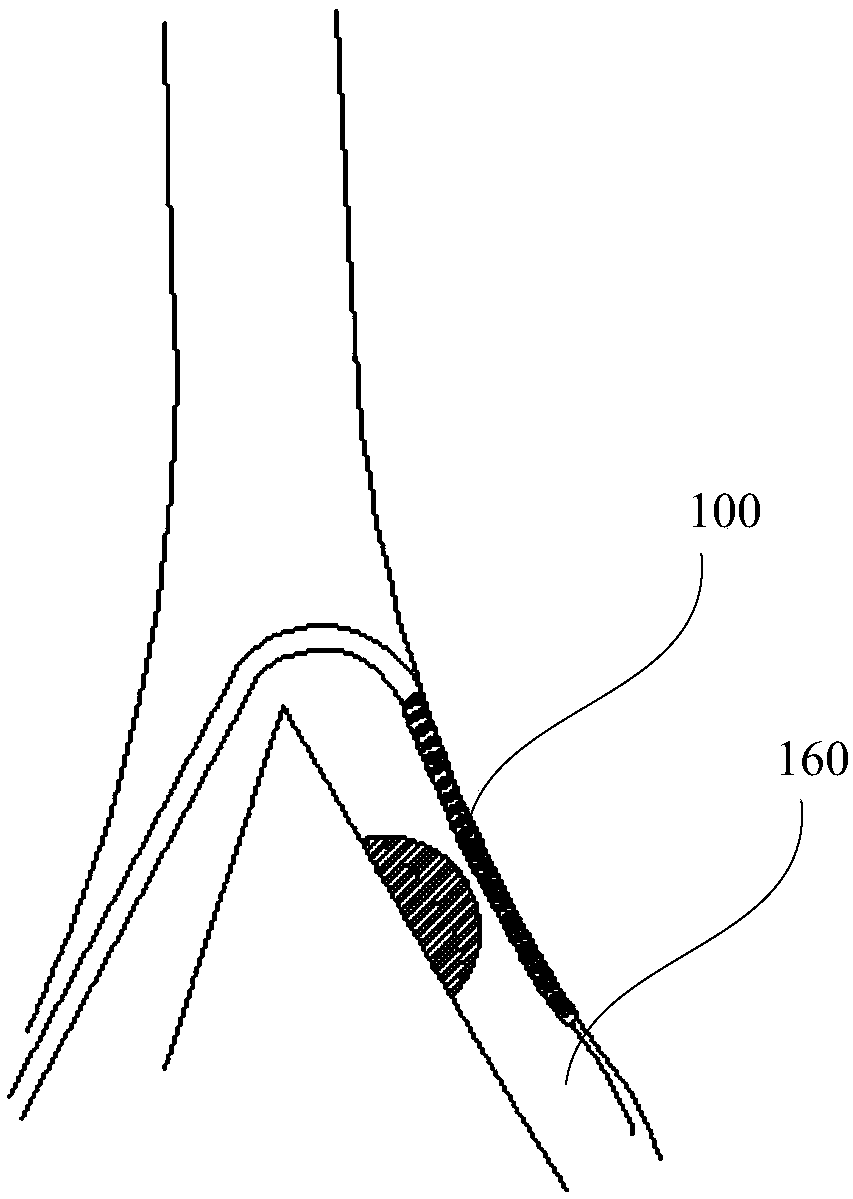

[0052] This embodiment provides a stent graft. Figure 6 It is a cross-sectional view of the stent graft in Example 3 of the present invention, refer to Figure 6 The difference between the stent-graft 100 in this embodiment and the stent-graft 100 in Embodiment 1 is that the inner layer of the stent-graft 130 in this embodiment is arranged at the proximal end of the skeleton 110 away from the skeleton 110 and In the area away from the distal end of the skeleton 110, that is, the length of the inner layer membrane 130 in the axial direction is smaller than the length of the stent graft 100, and both ends of the inner layer membrane 130 are not connected to the The two ends of the stent graft 100 overlap, and the adhesive sections 131 at both ends of the inner layer coating 130 are respectively bonded to the middle layer coating 122, and the separation section 132 of the inner layer coating 130 is connected to the middle layer The covering films 122 together form a hollow laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com