High-safety nickel-free metal drug-eluting vascular stent and manufacturing method thereof

A technology for vascular stents and manufacturing methods, which is applied in the field of nickel-free metal drug-eluting vascular stents and its manufacture, can solve the problems of stent segment restenosis, thrombus, and stent failure, and reduce the risk of thrombus, improve fatigue strength, and ensure safety sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

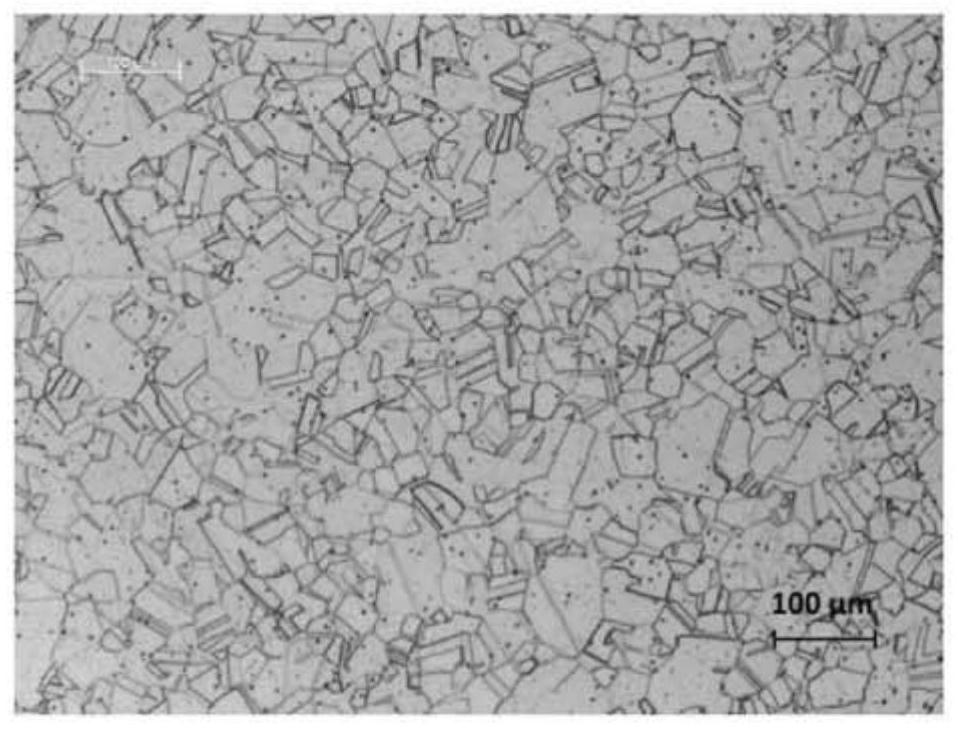

[0064] Example 1 High-nitrogen nickel-free austenitic stainless steel seamless thin-walled pipe 1

[0065] Take a forged high-nitrogen nickel-free stainless steel bar with a nitrogen content of 0.62% by weight and a manganese content of 15.4% by weight, and process it with a deep hole drilling machine to obtain a tube blank with a size of Φ30×6mm. The designed finished pipe size is Φ3.0×0.11mm. The number of cold deformation passes is 17, and the deformation amount of each pass is 40-50%. Each pass is divided into three cold deformations, and the deformation amount of each pass is 45-50%, 30-35%, and 20-25% of the deformation amount of the pass. After each cold deformation, the surface of the pipe is ultrasonically cleaned to remove surface lubricants. After drying, put it into a heat treatment furnace that can be vacuumed and pressurized. The material of the furnace is 2520 superalloy, and there are three temperature-measuring thermocouples to monitor the temperature in rea...

Embodiment 2

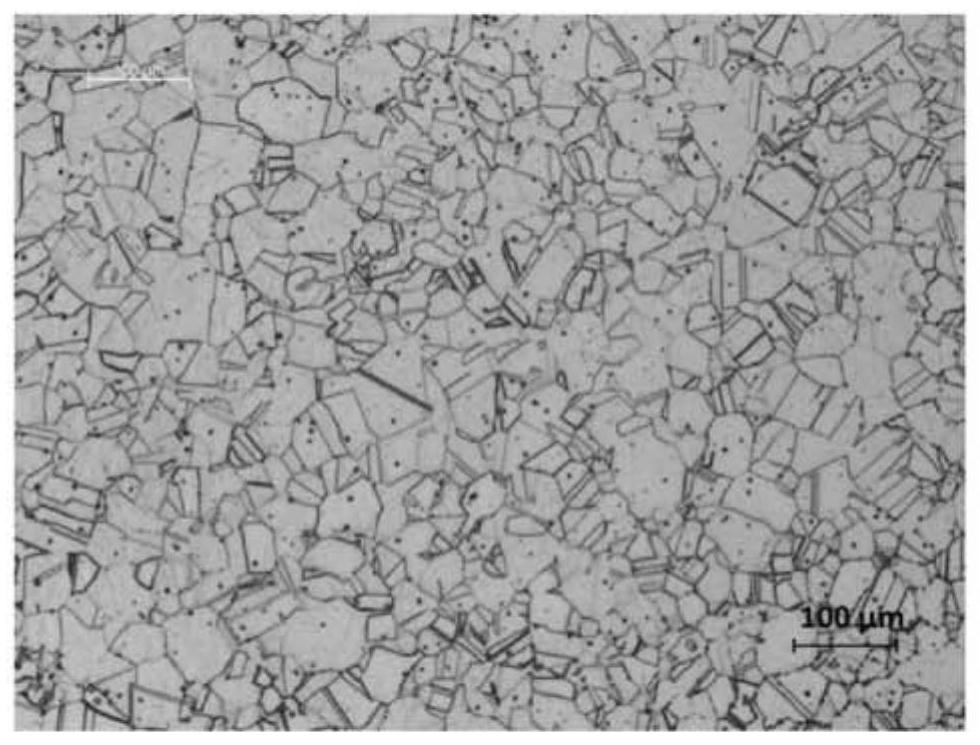

[0067] Example 2 High-nitrogen nickel-free austenitic stainless steel seamless thin-walled pipe 2

[0068]Take a forged high-nitrogen nickel-free stainless steel bar with a nitrogen content of 0.62% by weight and a manganese content of 15.4% by weight, and process it with a deep hole drilling machine to obtain a tube blank with a size of Φ30×6mm. The designed finished pipe size is Φ1.8×0.09mm. The number of cold deformation passes is 21, and the deformation amount of each pass is 40-50%. When the outer diameter of the pipe is ≥3.0mm, each pass is divided into three cold deformations, and the deformation amount of each pass is 45-50%, 30-35% and 20-25% of the deformation amount of the pass; when the outer diameter of the pipe is -1 Continue pumping for more than 10 minutes after Pa, and close the valve of the vacuum system. Fill the furnace with a mixture of nitrogen and argon, the total pressure is 0.25MPa, the ratio of nitrogen to argon is 1:4, that is, the partial pressure ...

Embodiment 3

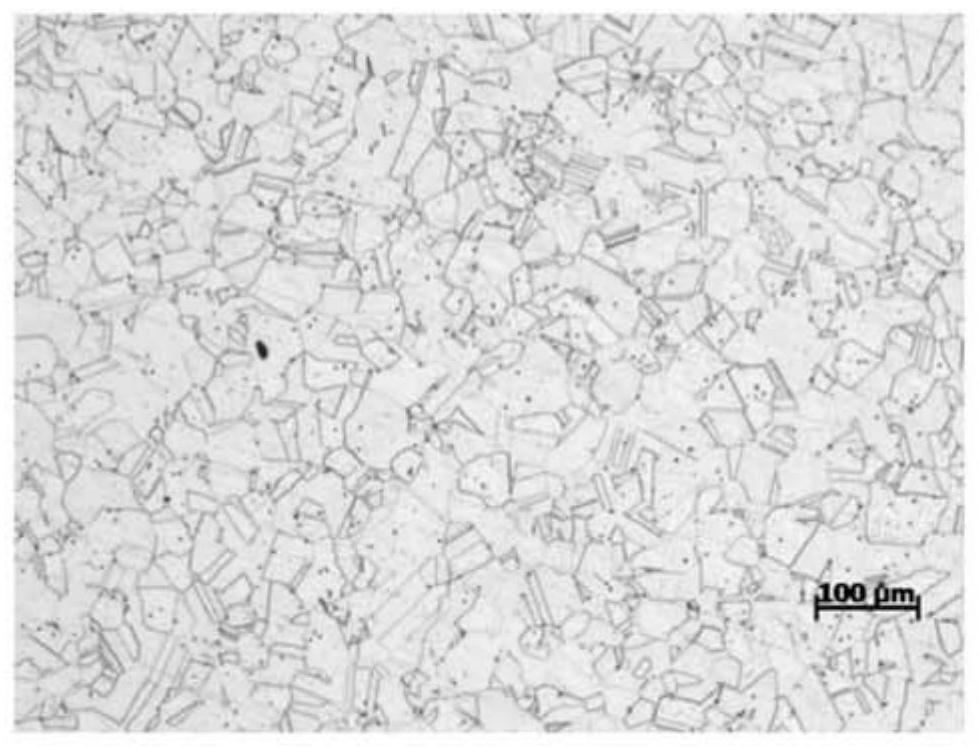

[0070] Example 3 High-nitrogen nickel-free austenitic stainless steel seamless thin-walled pipe 3

[0071] Take a forged high-nitrogen nickel-free stainless steel bar with a nitrogen content of 0.62% by weight and a manganese content of 15.4% by weight, and process it with a deep hole drilling machine to obtain a tube blank with a size of Φ30×6mm. The designed finished pipe size is Φ4.5×0.19mm. The number of cold deformation passes is 15, and the deformation amount of each pass is 40-50%. Each pass is divided into three cold deformations, and the deformation amount of each pass is 45-50%, 30-35%, and 20-25% of the deformation amount of the pass. After each cold deformation, the surface of the pipe is ultrasonically cleaned to remove surface lubricants. After drying, put it into a heat treatment furnace that can be vacuumed and pressurized. The material of the furnace is 2520 superalloy, and there are three temperature-measuring thermocouples to monitor the temperature in rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com