Degradable drug-eluting stent with hydrophobic structure on surface and manufacturing method thereof

A technology of elution stent and manufacturing method, applied in the field of medical devices, can solve the problems of smooth muscle cell proliferation, reduce drug release time, drug loss, etc., and achieve the effects of slowing elution effect, reducing energy consumption, and reducing expenditure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Adopting wire cutting means to make an injection mold capable of realizing the integrated molding of the designed support structure, the injection mold is composed of the movable mold insert and the fixed mold insert required by the microcolumn structure support, the standard movable template and the fixed mold pull, and The required side draw and tie rod structure;

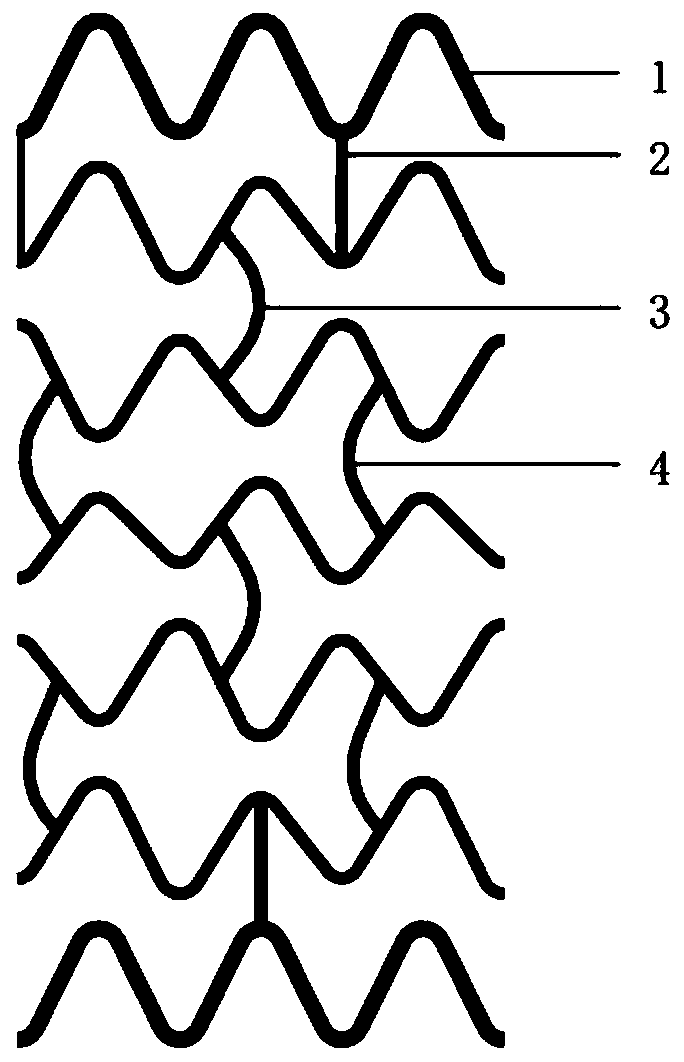

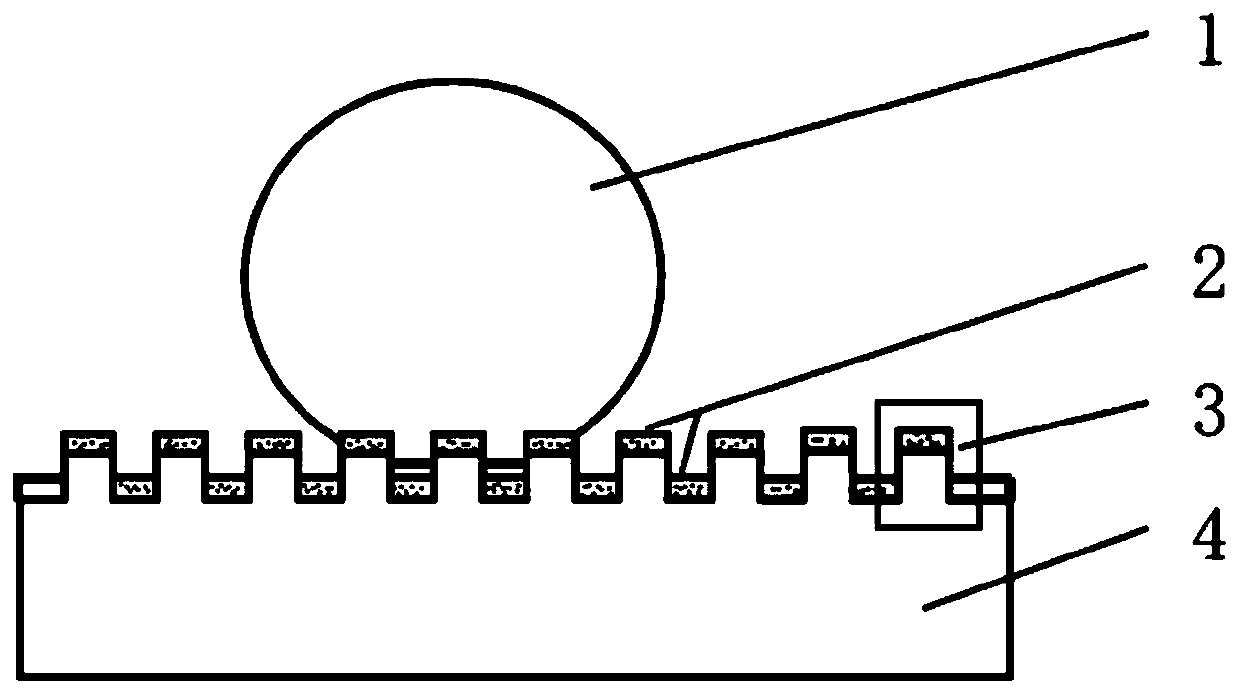

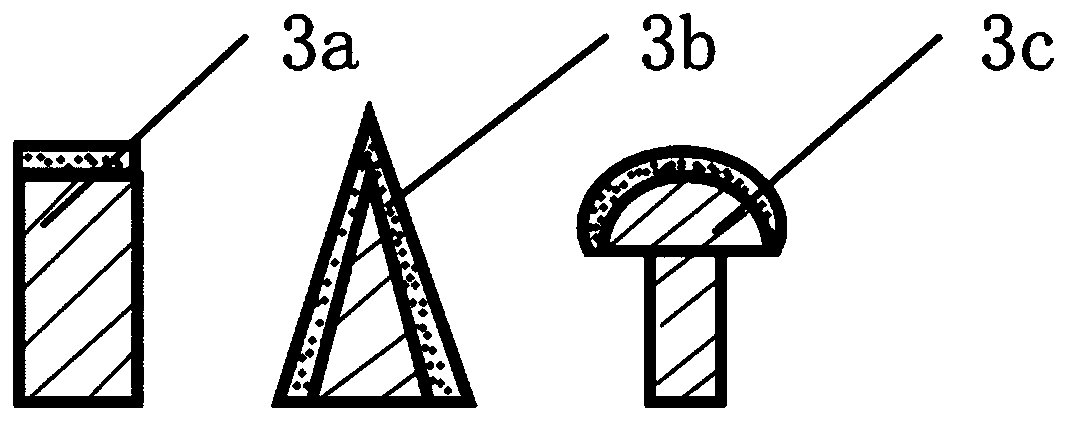

[0040] (2) Install the injection mold into the injection molding machine, adjust the injection temperature and injection pressure required for the bracket material, perform injection molding, and take out the processed bracket with micro-column structure and micro-structure micro-column after cooling and mold opening The shape is "cylindrical". The diameter of the microcolumns is 0.3mm, the height is 0.2mm, and the distance between the centers of the microcolumns is 0.50mm. The liquid contact angle is greater than 150°, the number of waveforms of the contoured support unit 1 is m=6, and the surface mi...

Embodiment 2

[0044] (1) Utilize an extruder to manufacture microtubes with the same diameter as the support;

[0045] (2) Using laser engraving technology to cut the surface of the microtubules to process the drug-eluting stent structure;

[0046] (3) Laser etching or 3D printing is used again to process the microstructure on the surface of the stent, and the shape of the microcolumn of the microstructure is "conical", such as image 3 Shown in 3b. This microstructure reduces the resistance of the stent in the blood vessel lumen to blood flow and reduces the internal stress of the stent.

[0047] (4) and (5) steps are with (3) and (4) steps in embodiment 1.

Embodiment 3

[0049] (1) 3D printing technology is used to form the biodegradable drug-eluting stent and the surface microstructure designed by the present invention at one time. The micro-pillar shape of the microstructure is "cap-shaped", such as image 3 Shown in 3c.

[0050] All the other steps are the same as (3) and (4) steps in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com