Method and device for pumping high-concentration bottom sludge with constant torque for mud scraper in sedimentation tank

A technology of sedimentation tank and mud scraper, which is applied in the feeding/discharging device, separation method, sedimentation separation, etc. of sedimentation tank to achieve the effect of stable concentration and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in conjunction with accompanying drawing and specific embodiment;

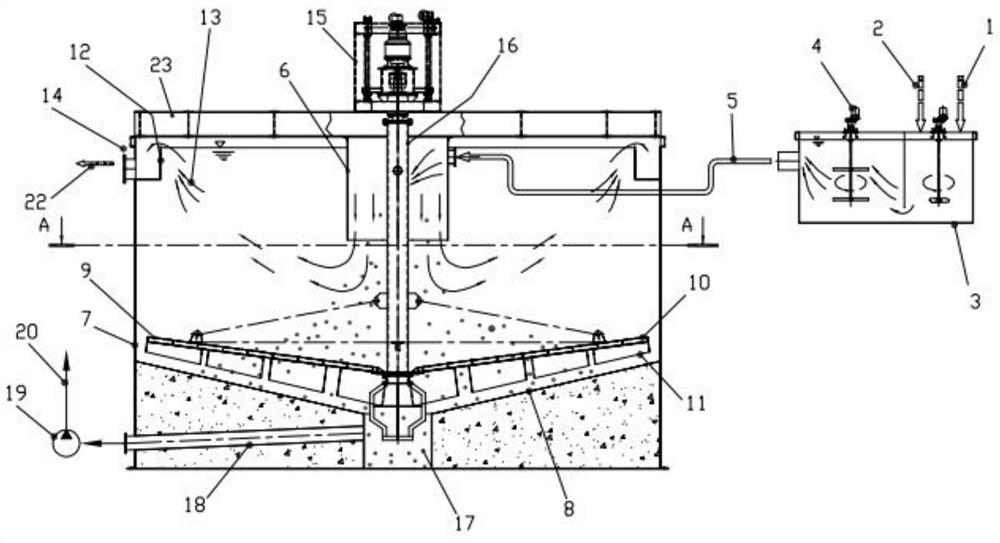

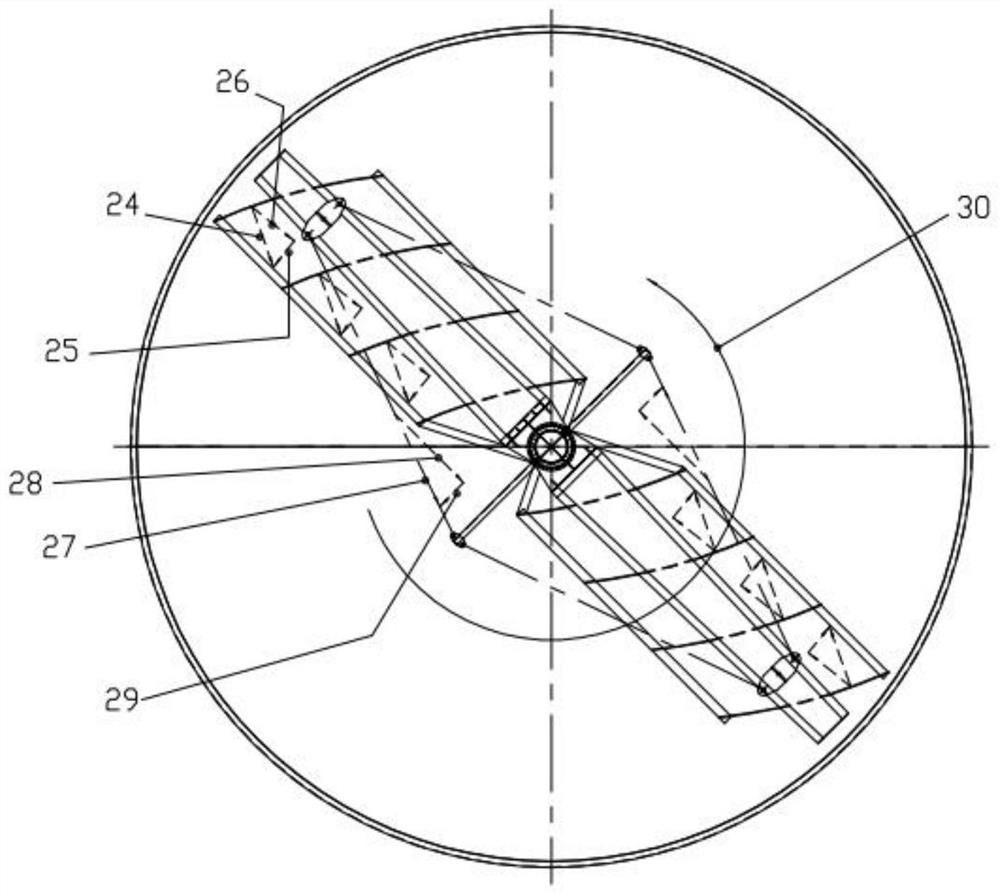

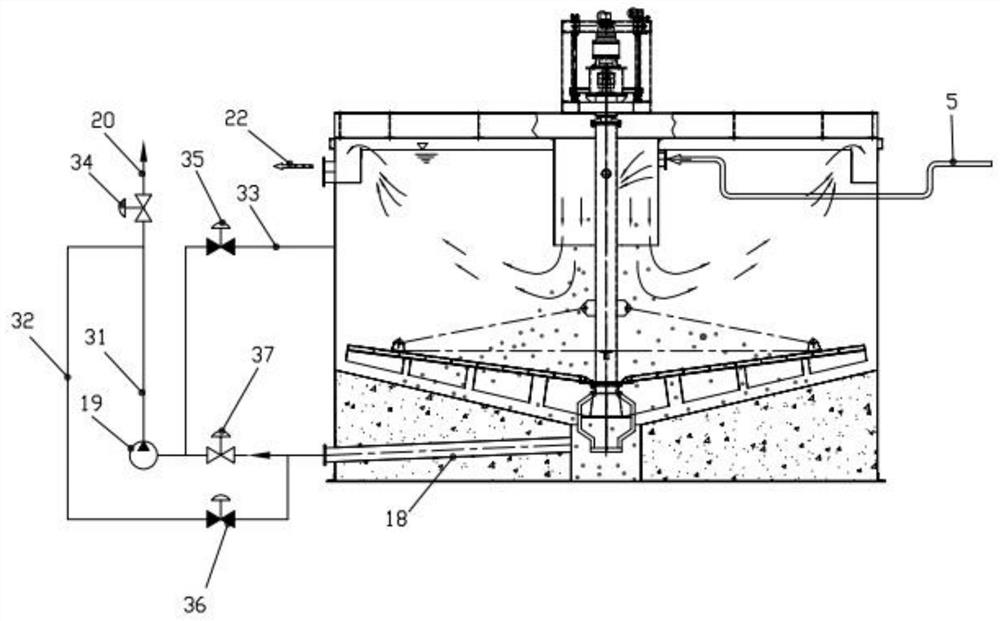

[0025] Such as figure 2 As shown, when the sludge scraper in the sedimentation tank performs the mud scraping operation, the sludge in the sedimentation tank is not only pushed toward the center of the circle by the force of the scraper 11, but also moves the bottom mud to the center of the pool along the slope of the bottom of the pool inclined toward the center by gravity. The scraper 11 is welded on the scraper arm 10 and is inclined at a certain angle to the axis of the scraper arm 10, so that the normal line of the tangent to the outer diameter of the arc of the scraper 11 has a centripetal thrust 26 facing the center of the pool, and the centripetal thrust 26 It is enough to scrape the sediment to the mud collecting chamber 17 in the center of the sedimentation tank, and then use the mud pump 19 to pump out the bottom mud of the mud collectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com