A method for reducing and decomposing phosphogypsum by carbonating tail gas of phosphogypsum

A phosphogypsum and carbonation technology, which is applied in chemical instruments and methods, inorganic chemistry, sulfur compounds, etc., can solve problems such as prone to reaction dead ends, difficulty in treating waste with waste, and weakened economy, so as to achieve harmless and outlet problems, alleviating the shortage of sulfur resources, and realizing the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

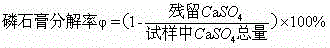

Image

Examples

Embodiment 1

[0035] The method for reducing and decomposing phosphogypsum carbonation tail gas described in this embodiment uses phosphogypsum carbonation tail gas as reducing gas, and H in the tail gas 2 The volume percentage of S is 60%, CO 2 The volume percentage content is 40%. Specifically include the following steps:

[0036] (1) Phosphogypsum is naturally air-dried, crushed, ground, and sieved to obtain phosphogypsum powder with a particle size of 120 mesh;

[0037] (2) Put the phosphogypsum powder in the reduction and decomposition furnace, pass through the carbonation tail gas of phosphogypsum, and control the CaSO in the phosphogypsum 4 H in tail gas carbonation with phosphogypsum 2 The molar ratio of S is 3:2, the furnace temperature is controlled at 700°C, the reaction is for 3 hours, and the SO in the furnace gas is continuously detected online with a flue gas analyzer 2volume percentage, SO 2 The volume percentage is 14%-16%, until the reaction is complete, stop heating ...

Embodiment 2

[0041] The method for reducing and decomposing phosphogypsum carbonation tail gas described in this embodiment uses phosphogypsum carbonation tail gas as reducing gas, and H in the tail gas 2 The volume percentage of S is 55%, CO 2 The volume percentage is 45%. Specifically include the following steps:

[0042] (1) Phosphogypsum is naturally air-dried, crushed, ground, and sieved to obtain phosphogypsum powder with a particle size of 120 mesh;

[0043] (2) Put the phosphogypsum powder in the reduction and decomposition furnace, pass through the carbonation tail gas of phosphogypsum, and control the CaSO in the phosphogypsum 4 H in tail gas carbonation with phosphogypsum 2 The S molar ratio is 3:1.8, the furnace temperature is controlled at 780°C, and the reaction is 2.5 hours, and the SO in the furnace gas is continuously detected online with a flue gas analyzer 2 volume percentage, SO 2 The volume percentage is 15%-17%, until the reaction is complete, stop heating the re...

Embodiment 3

[0047] The method for reducing and decomposing phosphogypsum carbonation tail gas described in this embodiment uses phosphogypsum carbonation tail gas as reducing gas, and H in the tail gas 2 The volume percentage of S is 5%, CO 2 The volume percentage content is 95%. Specifically include the following steps:

[0048] (1) Phosphogypsum is naturally air-dried, crushed, ground, and sieved to obtain phosphogypsum powder with a particle size of 120 mesh;

[0049] (2) Put the phosphogypsum powder in the reduction and decomposition furnace, pass through the carbonation tail gas of phosphogypsum, and control the CaSO in the phosphogypsum 4 H in tail gas carbonation with phosphogypsum 2 The S molar ratio is 3:0.8, the furnace temperature is controlled at 850°C, the reaction is 0.5 hours, and the SO in the furnace gas is continuously detected online with a flue gas analyzer 2 volume percentage, SO 2 The volume percentage is 17%-20%, until the reaction is complete, stop heating the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com