Double station annular pipe fitting circumferential laser welding machine and method

A technology of laser welding machine and annular pipe fittings, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of poor stability, unfavorable welding processing of annular pipe fittings, complex structure of laser welding machine, etc., to avoid offset, improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained below in conjunction with specific embodiments.

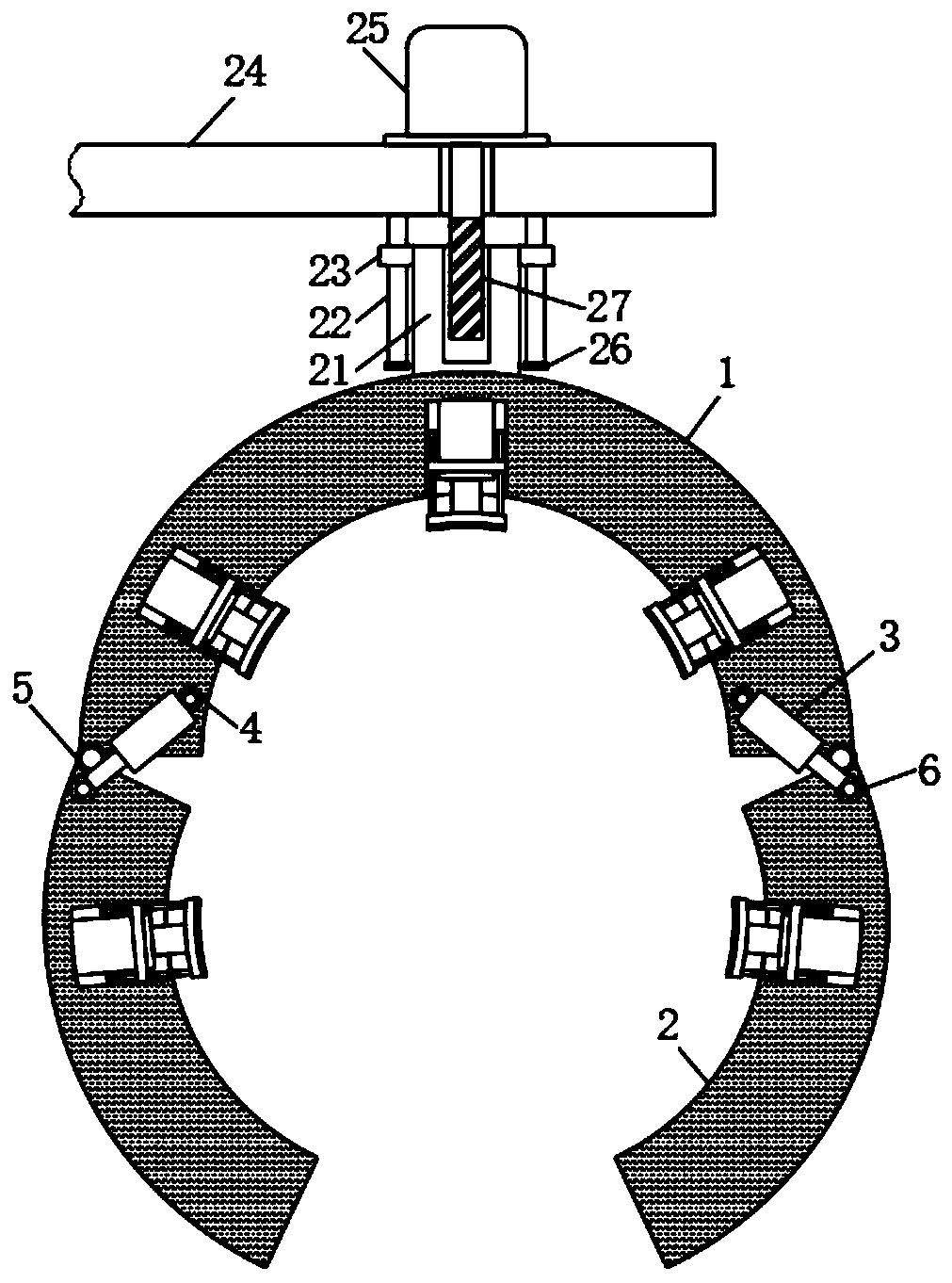

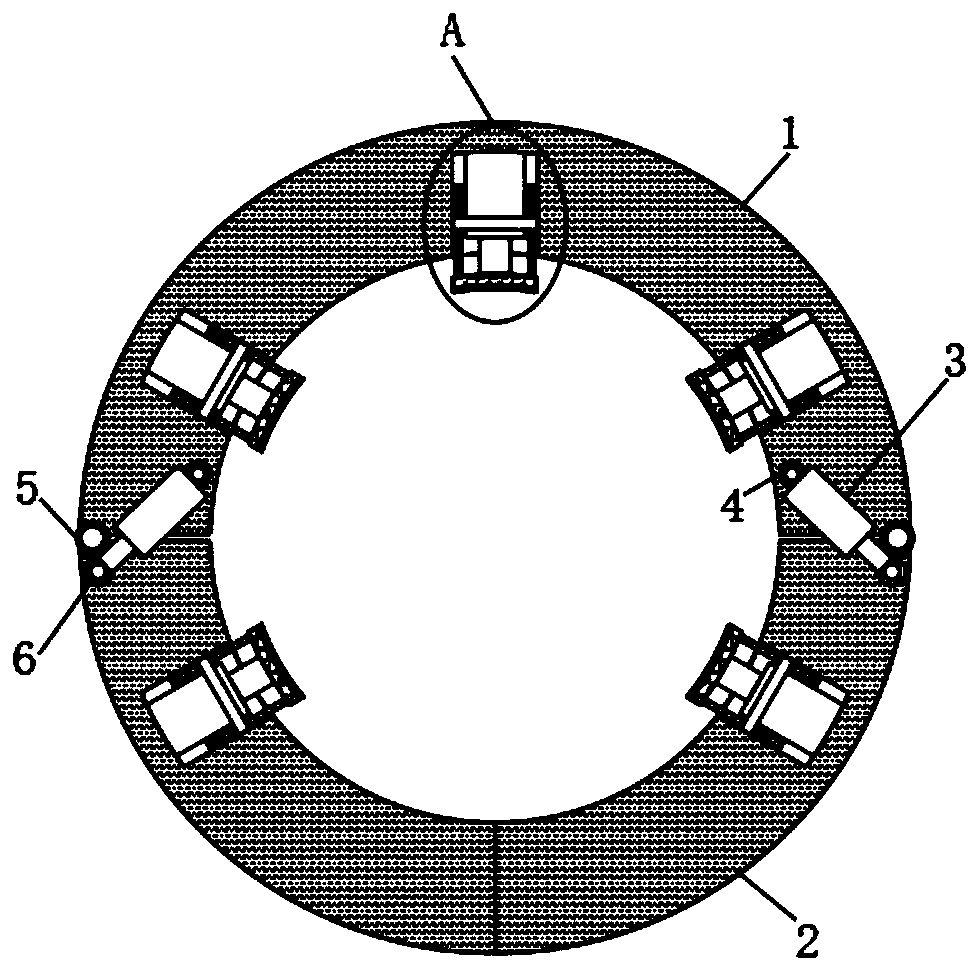

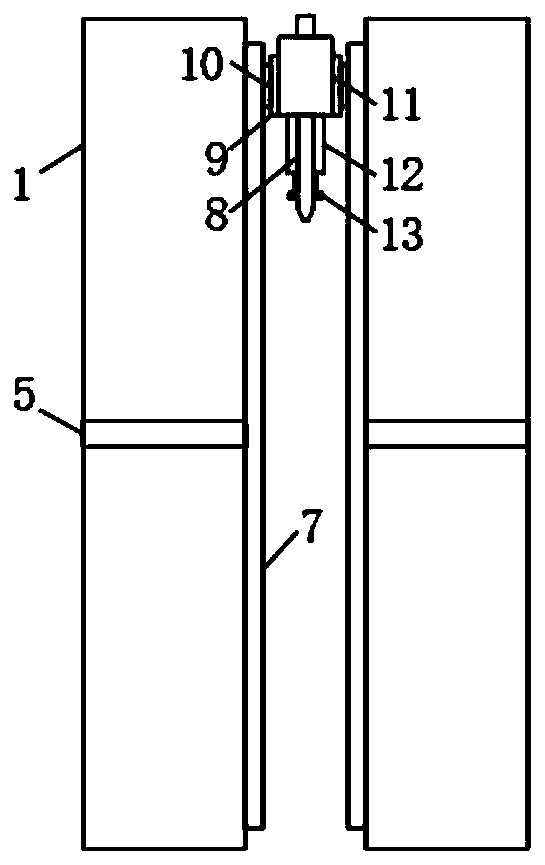

[0027] The dual-station annular pipe fitting circumferential laser welding machine proposed by the present invention includes a mounting bracket 24 installed on the surface of the wall, and the lower end of the mounting bracket 24 is symmetrically provided with two first clamping shells 1, and the two first clamping shells The middle part of the upper end of the housing 1 is fixedly connected with a connecting plate 21. A lifting mechanism for the first clamping housing 1 to move up and down is arranged between the connecting plate 21 and the mounting bracket 24. The two ends of the first clamping housing 1 Both are connected with the second clamping shell 2 through the rotation shaft 5, and a closing mechanism is arranged between the first clamping shell 1 and the second clamping shell 2, and the first clamping shell 1 and the second clamping shell The inside of the body 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com