Induction quenching device for large bearing race track surface

A bearing seat ring, induction hardening technology, applied in the direction of quenching device, furnace type, process efficiency improvement, etc., can solve the problems of difficulty in reaching the temperature required for heat treatment, shortening the service life of large bearings, shallow quenching and hardening layer, etc. Wide range, improved wear resistance, uniform effect of quench hardened layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

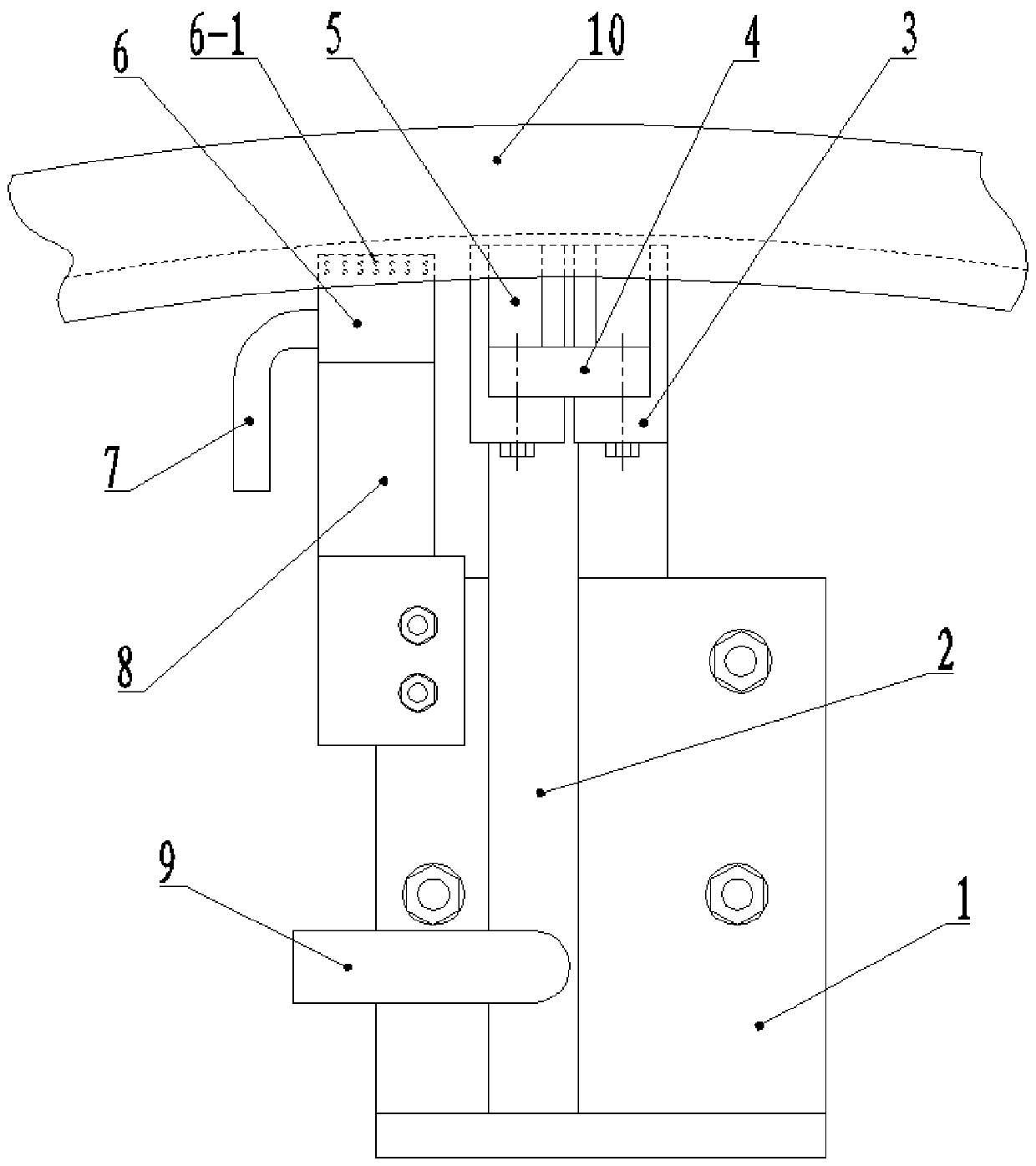

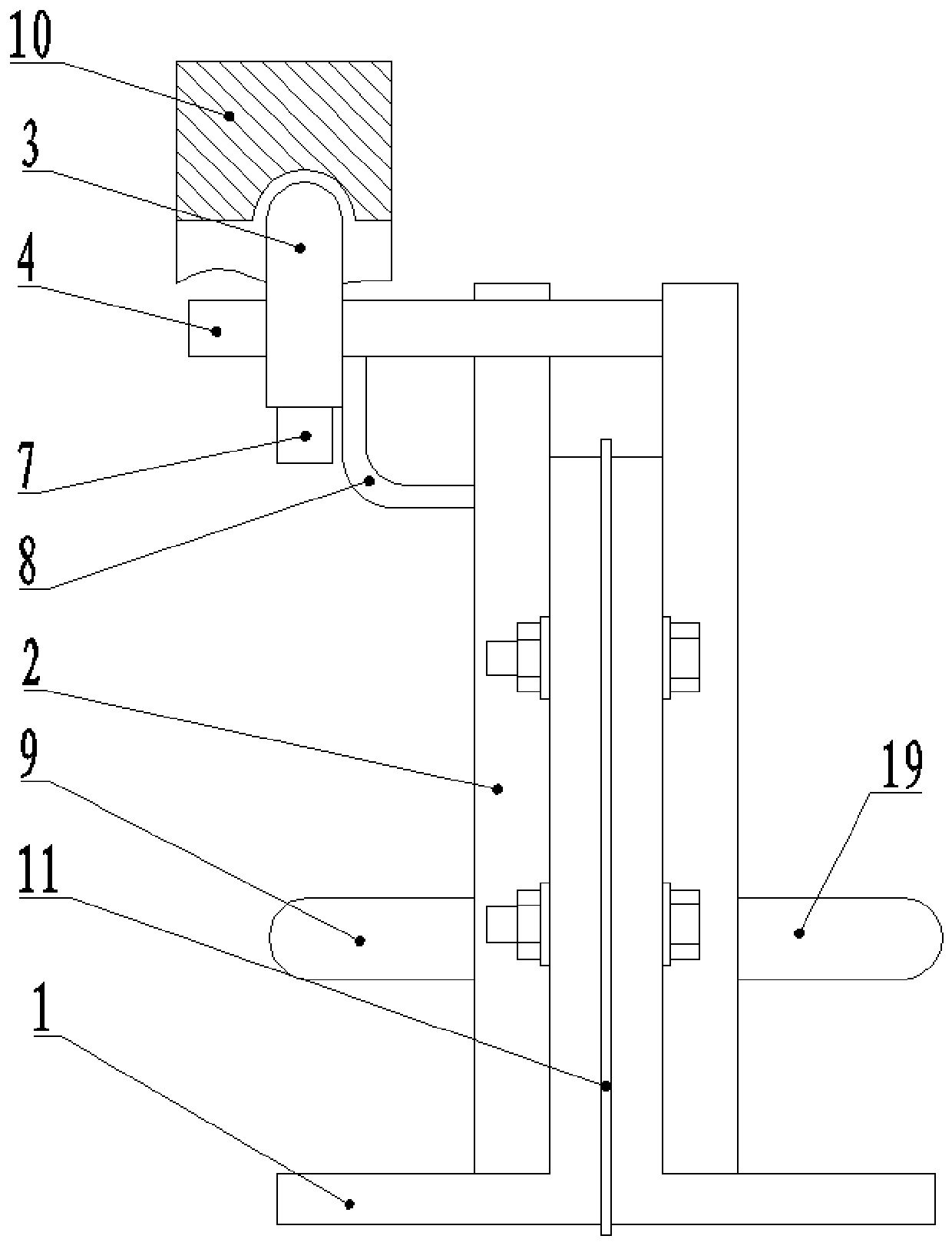

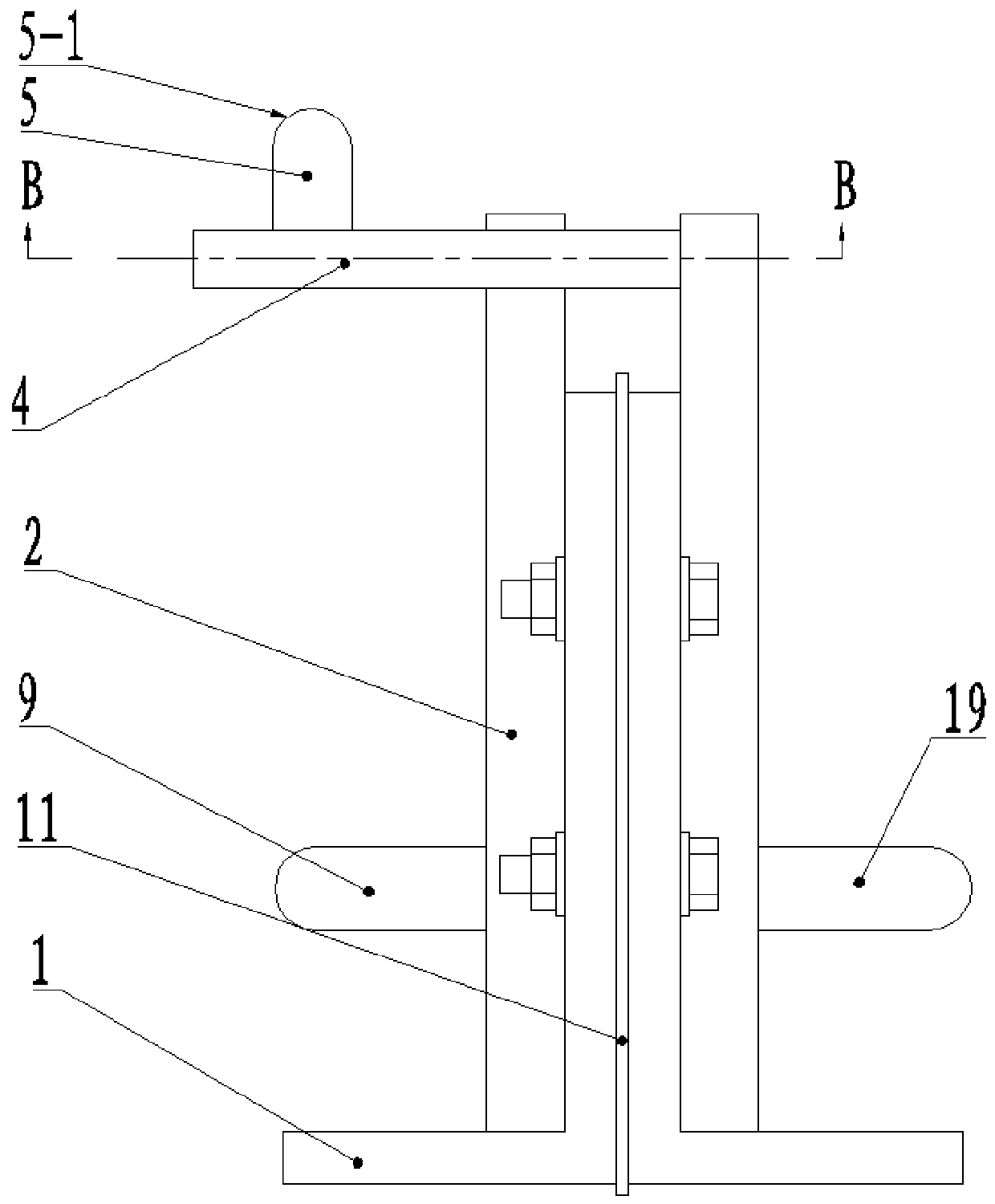

[0031] see Figure 1 to Figure 8 , an induction hardening device for the track surface of a large bearing seat ring, including two mounting seats 1 symmetrically arranged, and an induction body 2 is respectively fixed on the opposite sides of the two installation seats 1, and each induction body 2 extends upward. The ends of two straight arms 4 - 1 of a "U"-shaped induction coil 4 are respectively fixedly connected with the upper ends of two induction bodies 2 , and the two straight arms 4 - 1 of the induction coil 4 are both perpendicular to the induction body 2 . The upper end surfaces of the two straight arms 4-1 are respectively fixed with a vertically upwardly extending sensing part 5, and the two sensing parts 5 are arranged side by side, and the upper ends of each sensing part 5 are respectively provided with corresponding to the arc-shaped track surface of the large bearing race. The arc surface 5-1, the radius of the arc surface 5-1 of the induction part 5 is 2mm smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com