Steam-cleaning-free ultrafine disperse dye color paste preparation method

A disperse dye and ultra-fine technology, applied in the field of polyester short-process dyeing, can solve the problems of complex process, large sewage discharge, environmental pollution, etc., and achieve the effect of simple process, water saving and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment selects 110g / m 2 Polyester warp knitted fabric, the method used is as follows:

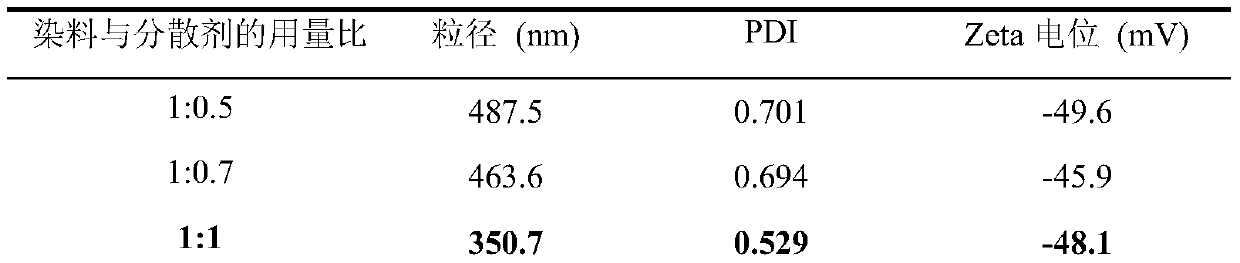

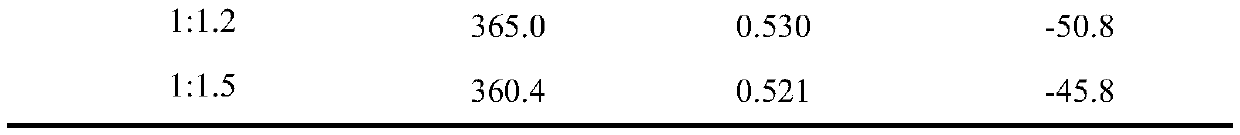

[0034] Process steps: Weigh disperse blue 291 and dispersant in different mass ratios (1:0.5, 1:0.7, 1:1, 1:1.2, 1:1.5) respectively in deionized water to make the whole system (including disperse dyes, The mass of dispersant, water) is 300g, the amount of disperse dye is 0.5-10%, 300g of zirconium beads are added, the speed of the grinder is 3000r / min, and the superfine disperse dye dispersion is obtained after grinding for 0.5h-1.5h.

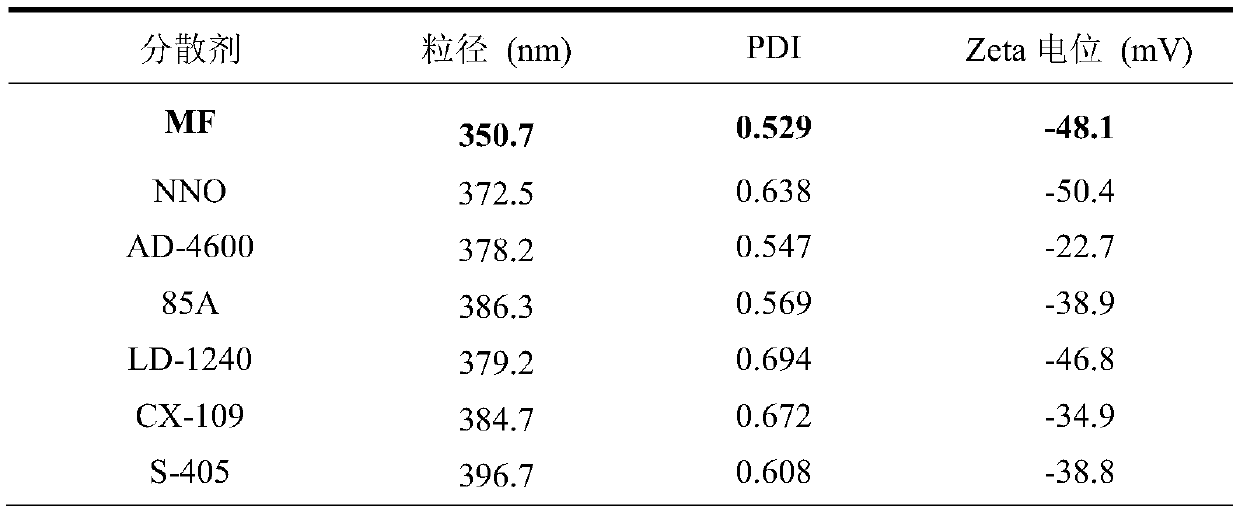

[0035] As shown in Table 1, when the amount of disperse dye is 2%, the mass ratio of dispersant to dye is 1:1, the mass of dispersion system is 300g, the mass of zirconium beads is 300g, and the grinding time is 1h, the dispersant MF can obtain the best Dispersion effect.

[0036] Table 1. Effect of dispersant type on particle size and Zeta potential of disperse blue 291 dye

[0037]

[0038] As shown in Tables 2 and 3, when the amount o...

Embodiment 2

[0047] This embodiment selects 110g / m 2 Polyester warp knitted fabric, the method used is as follows:

[0048] (1) Preparation of ultrafine disperse dye dispersion

[0049] Take disperse blue 291 and dispersant MF with a mass ratio of 1:1 in deionized water, make the quality of the whole system (including disperse dye, dispersant, water) 300g, the amount of disperse dye is 2%, add 300g zirconium beads, grinder The rotation speed is 3000r / min, and the superfine disperse dye dispersion can be obtained after grinding for 1 hour.

[0050] (2) Preparation of superfine disperse dye paste and pad dyeing

[0051] Add 3% anti-swimming agents PA, WA, FR, FR-A, KN-1304, FM, CSF-T700, FW-3300 respectively in the 45g ultrafine dispersion blue 291 dispersion that step (1) makes One, 9% curing agent GLT-2050B, 2% penetrating agent DM-1270, 2% high-temperature leveling agent DM-2115NA mixed evenly to obtain ultra-fine disperse dye color paste and transferred to the dye bath, using 10% Hyd...

Embodiment 3

[0057] This embodiment selects 110g / m 2 Polyester warp knitted fabric, the method used is as follows:

[0058] (1) Preparation of ultrafine disperse dye dispersion

[0059] Take disperse blue 291 and dispersant MF with a mass ratio of 1:1 in deionized water, make the quality of the whole system (including disperse dye, dispersant, water) 300g, the amount of disperse dye is 2%, add 300g zirconium beads, grinder The rotation speed is 3000r / min, and the superfine disperse dye dispersion can be obtained after grinding for 1 hour.

[0060] (2) Preparation of superfine disperse dye paste and pad dyeing

[0061] Add 2% anti-swimming agent PA, 9% curing agent (curing agent selects GLT-2050B, RG-B80, BL-223W, SSZ-181 in the 45g ultrafine dispersion blue 291 dispersion that step (1) makes One of them), 2% penetrating agent DM-1270, 2% high-temperature leveling agent DM-2115NA mixed evenly to obtain superfine disperse dye color paste and transferred to the dye bath, using 10% hydrochl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com