Smoke gas collecting hood

A technology of flue gas collection and I-beam, which is applied in the field of collecting hoods, can solve problems such as dust accumulation on the steel plate of the flue gas collecting hood, increased stress on the flue gas collecting hood, deformation of the flue gas collecting hood, etc., and achieves low production cost and excellent structure Simple and compact, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

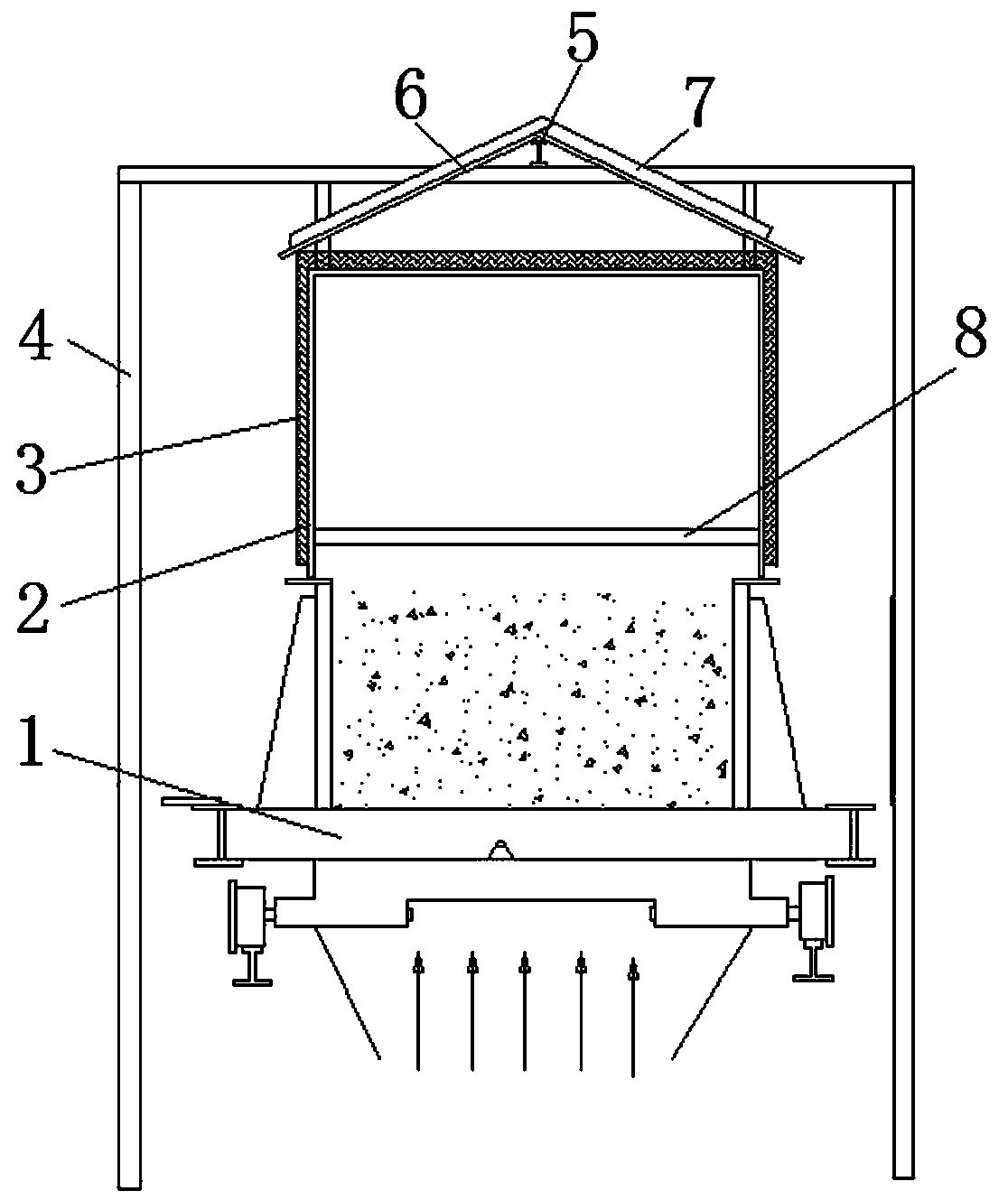

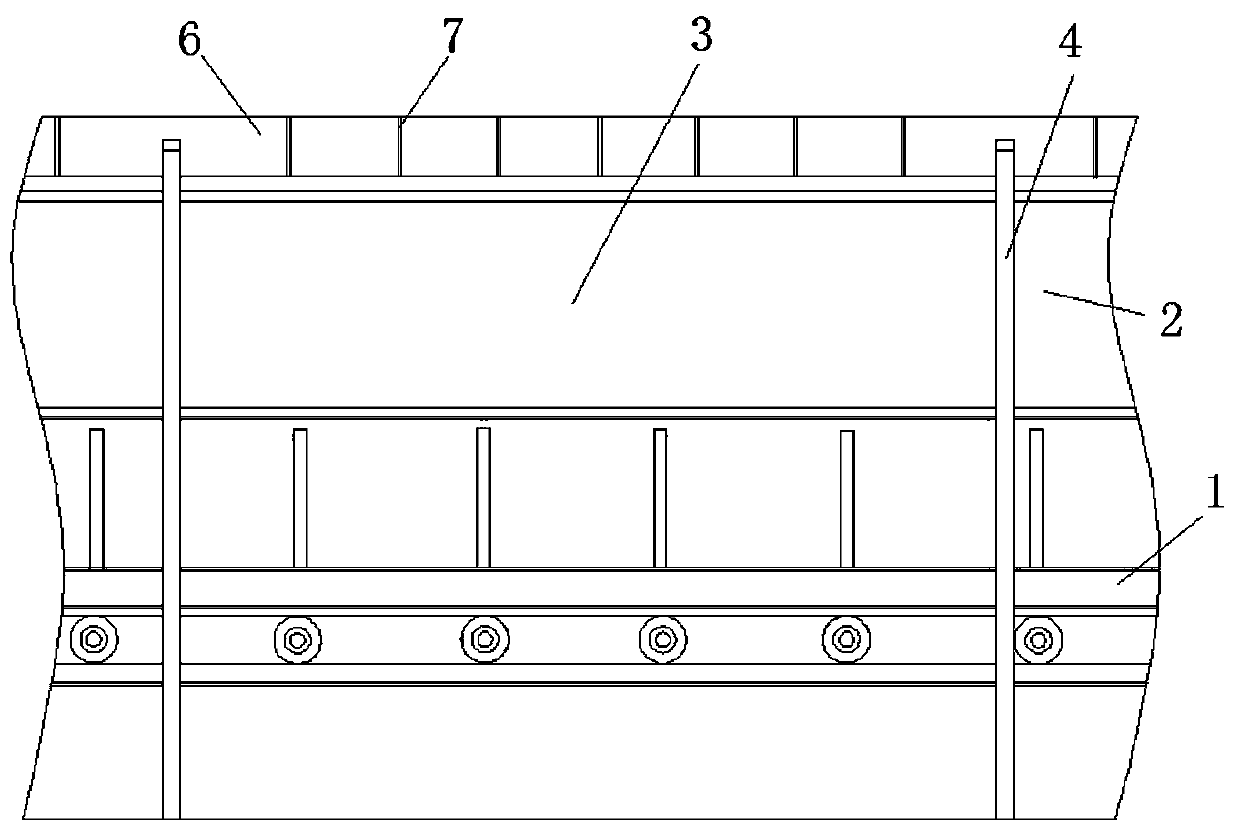

[0035] Such as figure 1 , figure 2 As shown, a flue gas collection hood 2 is arranged on the top of the annular cooler 1, and the outer walls of the flue gas collection hood 2 are covered with thermal insulation cotton 3, and the two opposite inner walls of the flue gas collection hood 2 A plurality of angle steels 8 are arranged horizontally, and the plurality of angle steels 8 are arranged in a criss-cross pattern; the top of the thermal insulation cotton 3 is provided with a partition assembly for keeping out rain or dust. Angle steels 8 are criss-crossed and horizontally arranged inside the collection cover 2, which improves the structural strength of the collection cover 2, making the collection cover 2 difficult to deform in the process of alternating cold and heat. Cost; the barrier component is used to keep out rain or dust, and the barrier component is in the shape of a roof, so the dust is not easy to gather. , dust will not accumulate on the collection cover 2. ...

Embodiment 2

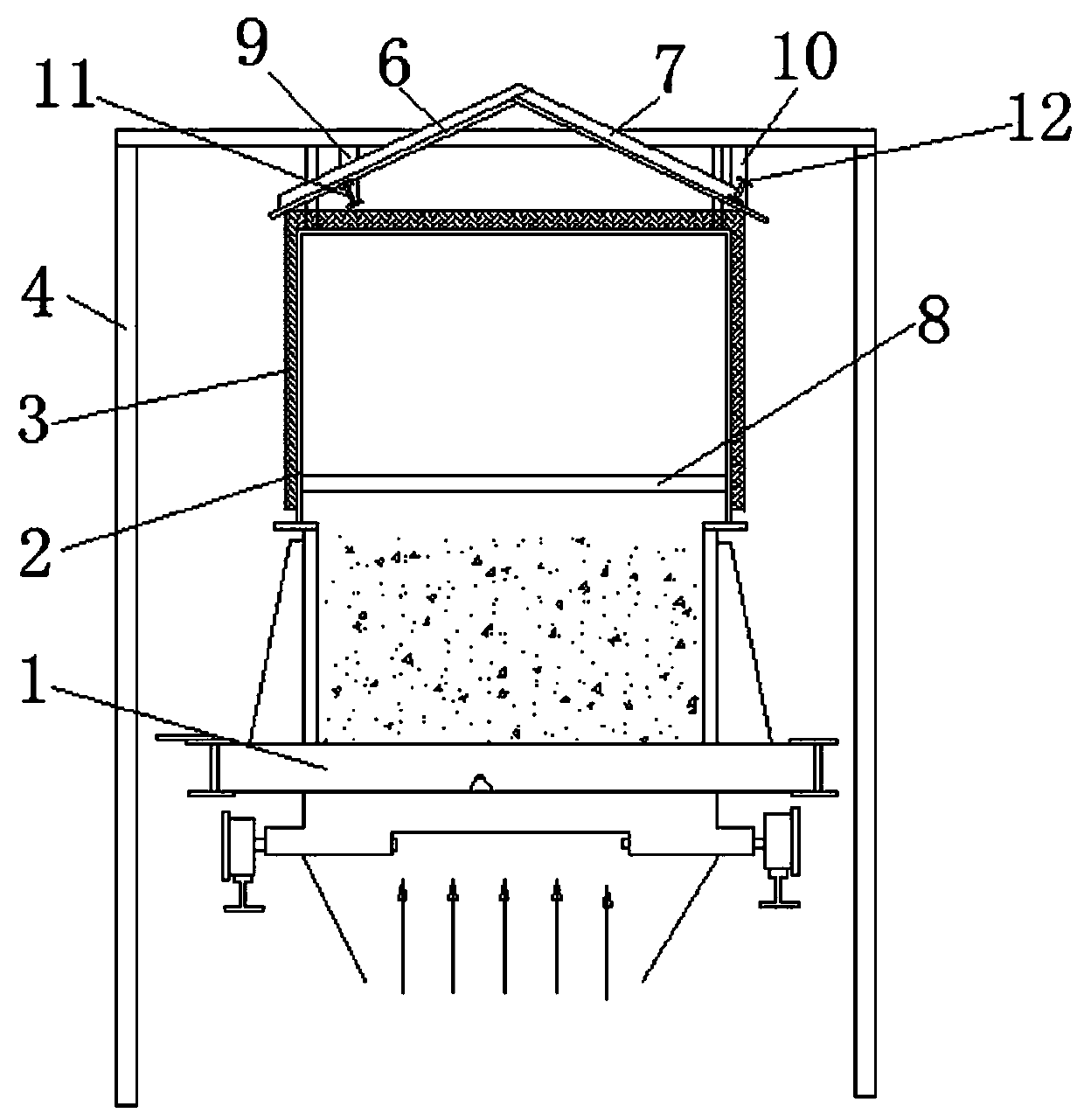

[0039] The difference from Embodiment 1 is that: image 3 As shown, each bracket 4 is provided with a first fixed plate 9 and a second fixed plate 10 at intervals, a first I-beam 11 is welded between two corresponding first fixed plates 9, and the other two corresponding A second I-beam 12 is welded between the second fixing plates 10, the first I-beam 11 is passed through the inner side of the partition assembly, the second I-beam 12 is located at the outer lower edge of the partition assembly, and the partition assembly Weld with the first I-beam 11 and the second I-beam 12 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com