Diameter measurement device and measurement method of inner groove

A technology of diameter measurement and inner diameter, applied in the field of machining, can solve the problems of insufficient range, insufficient precision, and difficult to complete, and achieve the effect of large contact area, stable measurement value, and error reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail through specific embodiments below.

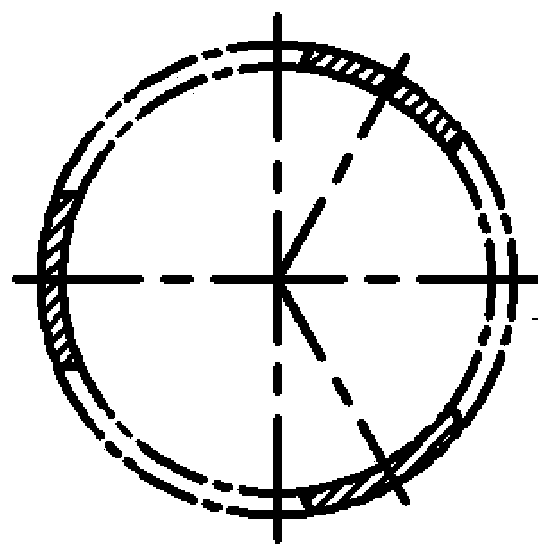

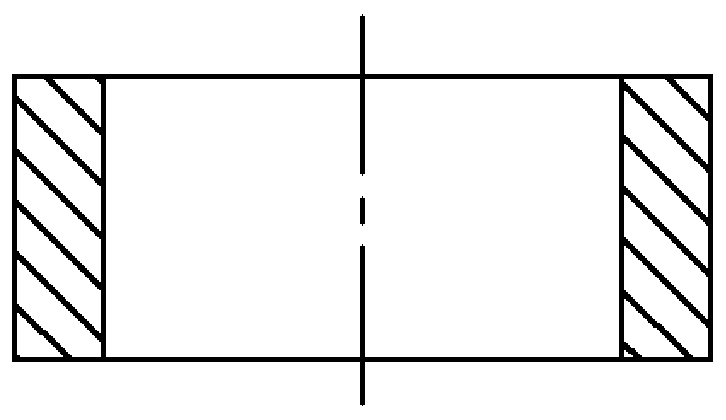

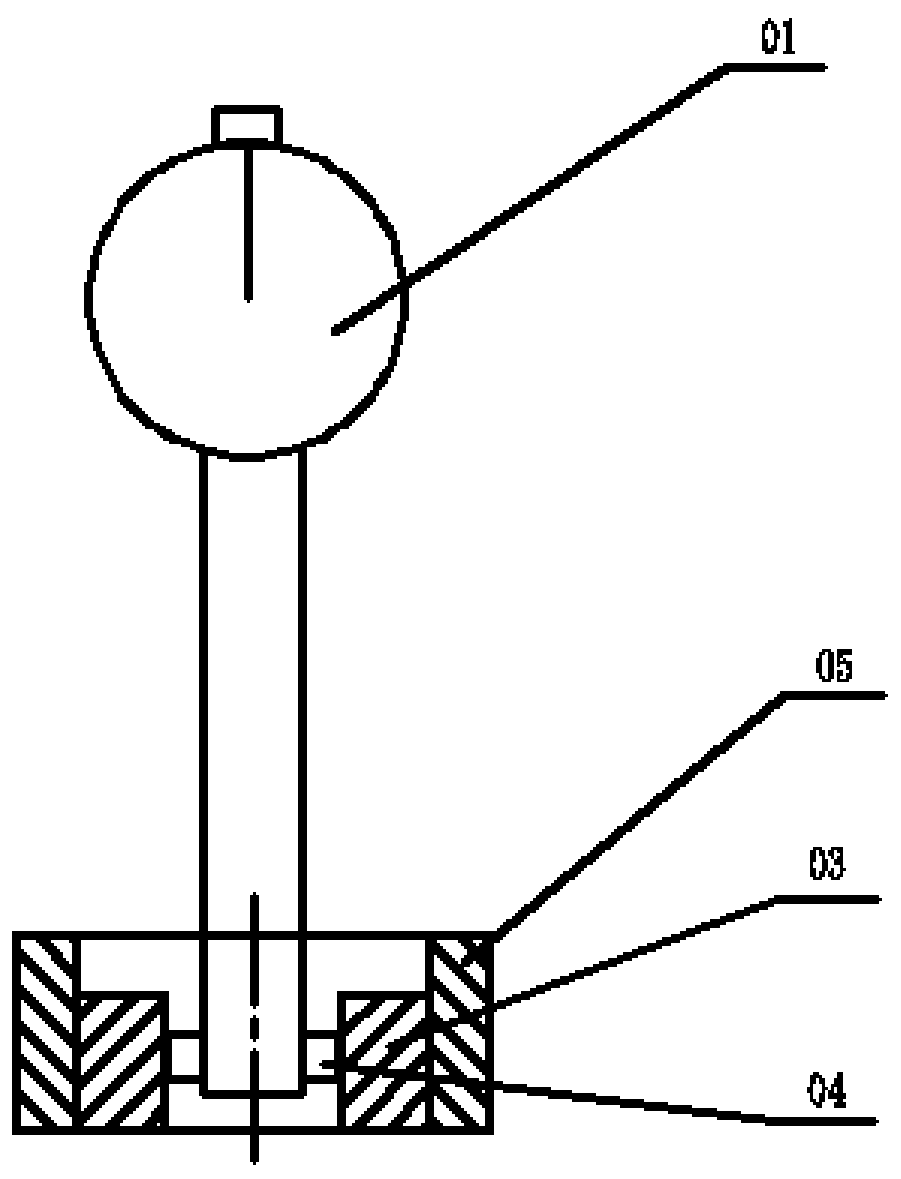

[0025] A device for measuring the diameter of an inner tank, characterized in that it includes a reference gasket 03, a diameter detection instrument 01, and a measuring instrument probe 04; the reference gasket 03 is a tile-shaped structure, and the reference gasket 03 has at least two sections Placed on the side wall of the inner groove of the part to be tested, it can be closely attached to the side wall of the inner groove, and the outer diameter is the same as the diameter of the inner groove of the part. The number is the same, and the measuring instrument probe 04 is installed on the measuring end of the diameter detection instrument 01, and the measuring instrument probe 04 is in contact with the reference gasket 03; it is preferably corresponding to the center point of the reference gasket 03; the diameter detection Apparatus 01 is an inner diameter dial indicator, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com