Device for collecting surface panorama images of shaft parts for defect identification

An image acquisition device and defect identification technology, which is applied to measuring devices, material analysis through optical means, instruments, etc., can solve the problems of increased worker inspection workload, large manual inspection workload, high error rate, etc., and achieve good environmental adaptation High performance, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

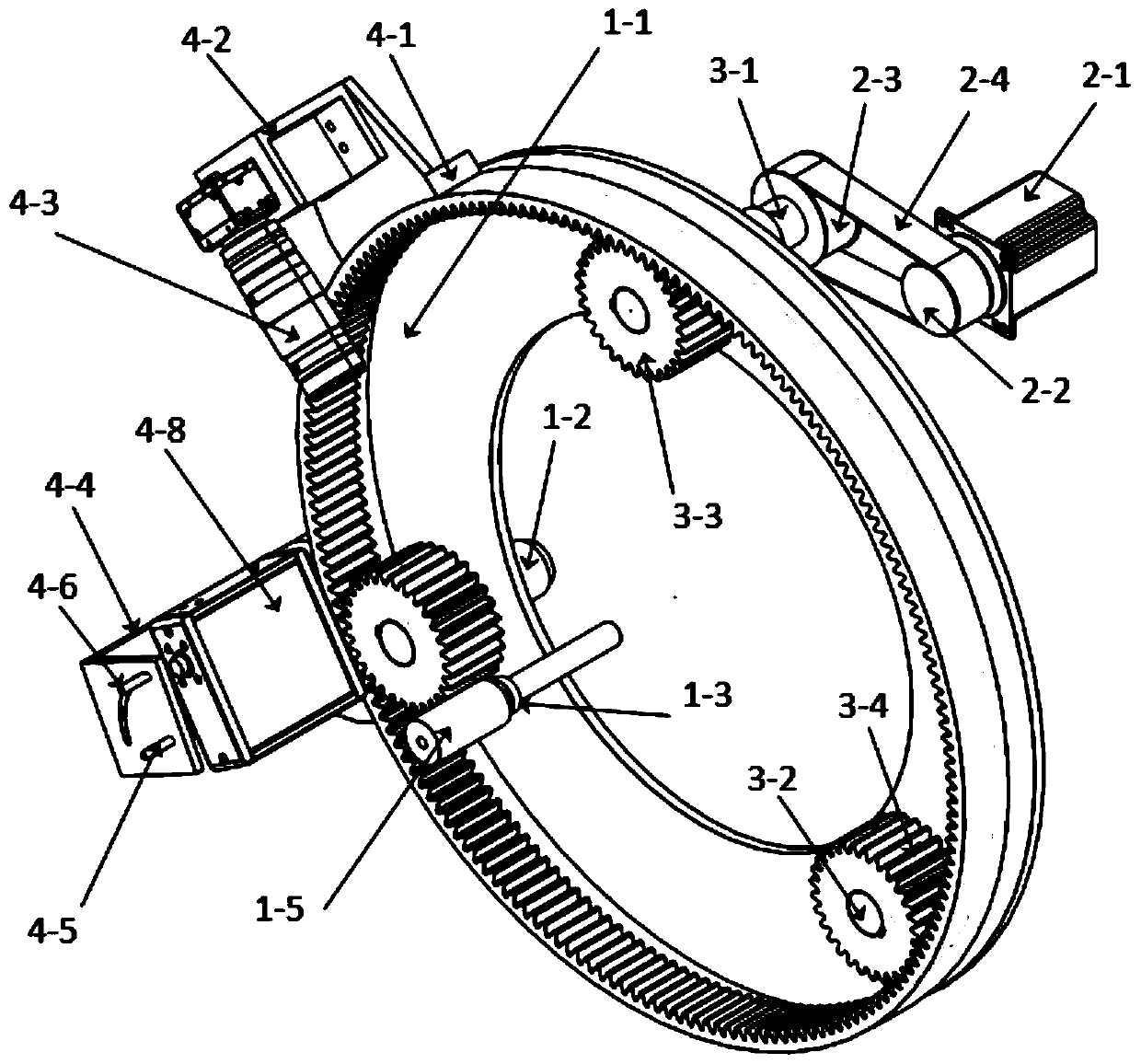

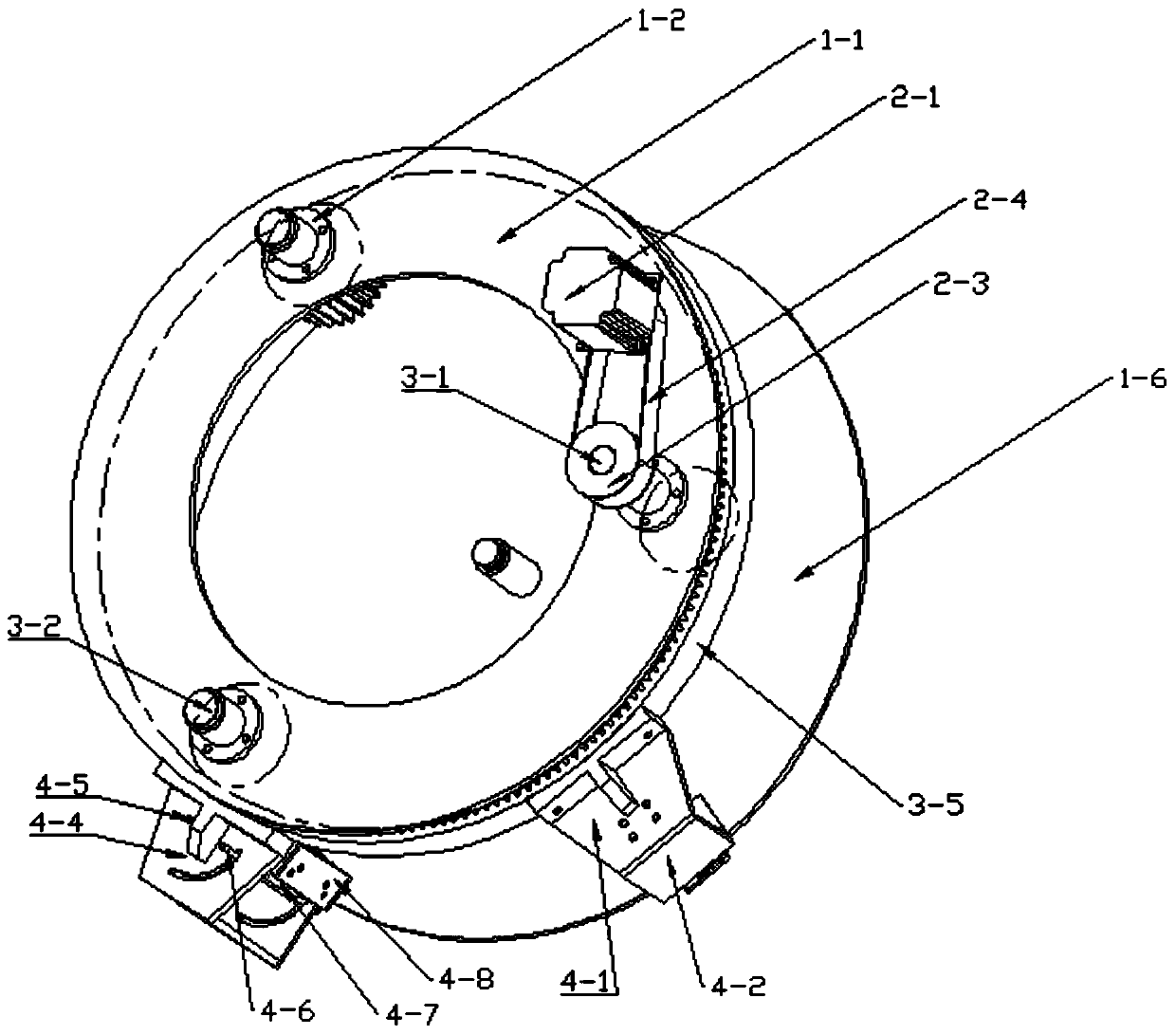

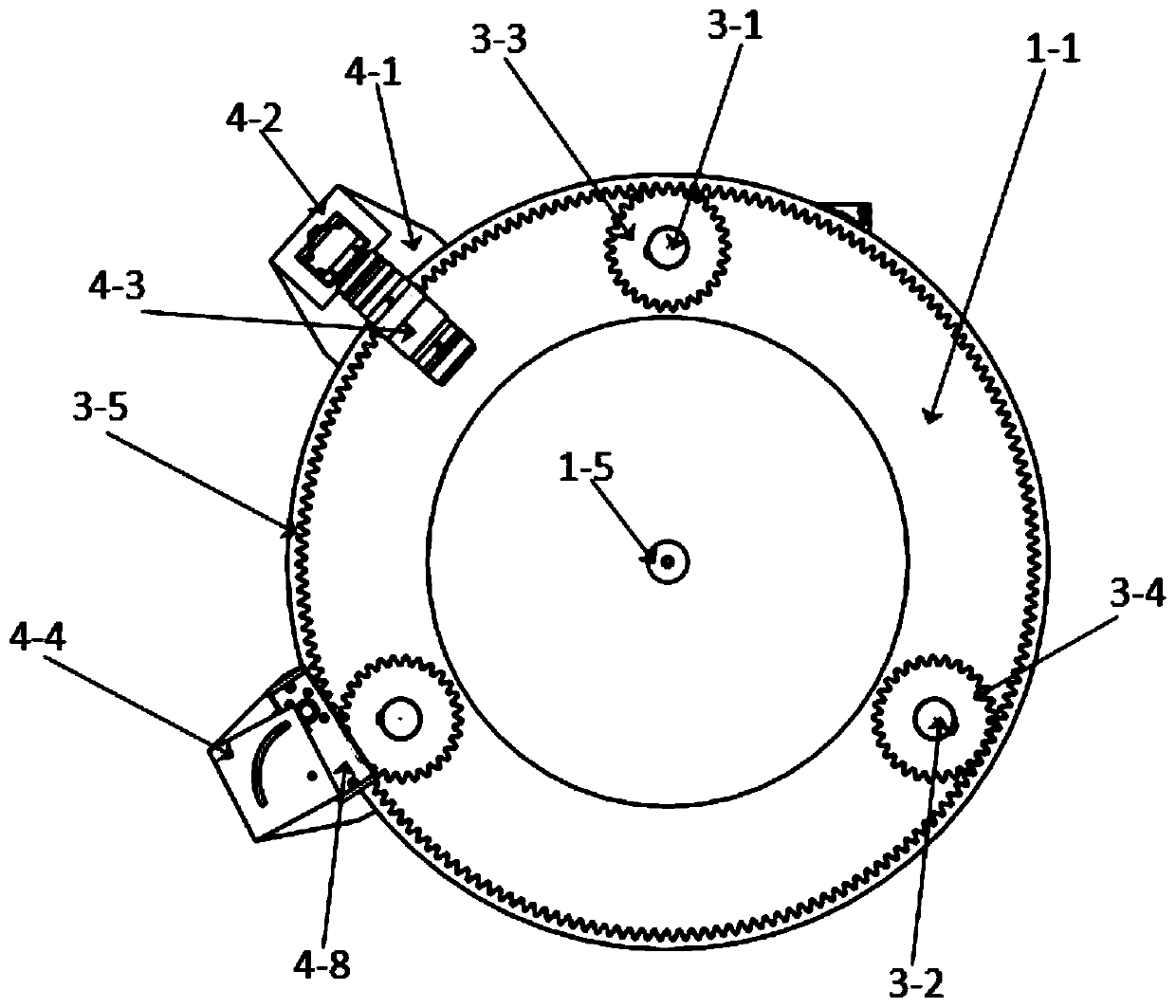

[0028] Such as figure 1 As shown, the present invention includes a support module, a power module, a transmission module and a detection module. The power module and the transmission module are respectively installed on the upper and lower sides of the support module, and the detection module is fixedly connected to the transmission module. The support module is used to support the whole device, the power module provides the operating power of the mechanism, and the transmission module is responsible for rotating the detection module with light source and camera at a certain speed to detect shaft parts.

[0029] Such as figure 1 As shown, the support module includes a frame 1-1, a sliding bearing 1-2, a positioning block 1-3 (for placing shaft parts), a spring 1-4 (for matching the positioning block), and a positioning sleeve 1-5 (for cooperating with the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com