Complete fiber-optic vector microphone probe

A microphone and vector technology, used in the measurement of ultrasonic/sonic/infrasonic waves, instruments, measuring devices, etc., can solve the problems of complex silicon micro-process flow, high phase matching requirements, and high background noise, and achieve easy formation of arrays, anti-electromagnetic Effects of strong interference ability, multiple selectivity and possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 1

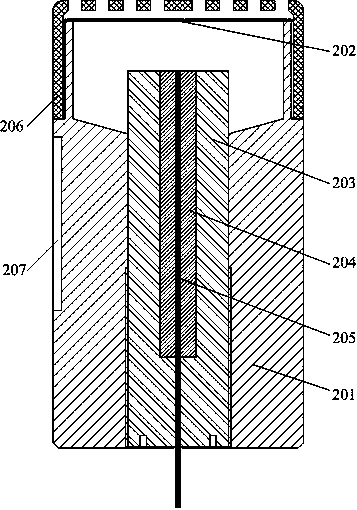

[0051] In the first embodiment of the present invention, a complete optical fiber vector microphone probe adopts a schematic cross-sectional view of a fiber optic scalar microphone probe structure that directly measures the acoustic signal scalar sound pressure P, as shown in FIG. figure 2 As shown, it includes: a structure 201, a diaphragm 202, a ferrule sleeve 203, a ferrule 204, a single-mode optical fiber 205, a mesh cover 206 and a groove 207 (the groove on the proximal surface is not shown). The optical fiber scalar microphone probe is based on the Fabry-Perot interferometer structure, and its specific composition is described as follows: the structure body 201 is a hollow structure, the uppermost cylindrical cavity structure is used to fix the diaphragm 202, and the lower part has A section of internal thread is used to fix ferrule sleeve 203 with corresponding external thread. The ferrule sleeve 203 is used to fix the ferrule 204 , and has ventilation slots for static...

no. 2 example

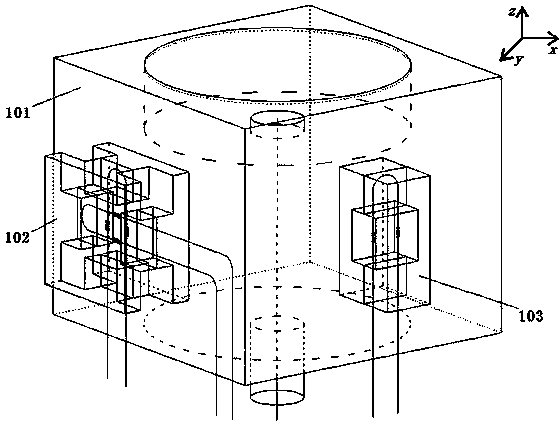

[0055] The second embodiment of the present invention is a preferred embodiment. Based on the structural characteristics of a complete optical fiber vector microphone probe of the present invention, the two-dimensional optical fiber vector microphone probe and the one-dimensional optical fiber vector microphone probe can also be designed and determined first, Then, based on the structural dimensions of the above two microphone probes, the dimensions of the corresponding grooves on the two adjacent surfaces are given to determine the design of the optical fiber scalar microphone probe, and finally the bonding assembly between all probes is completed according to the instructions.

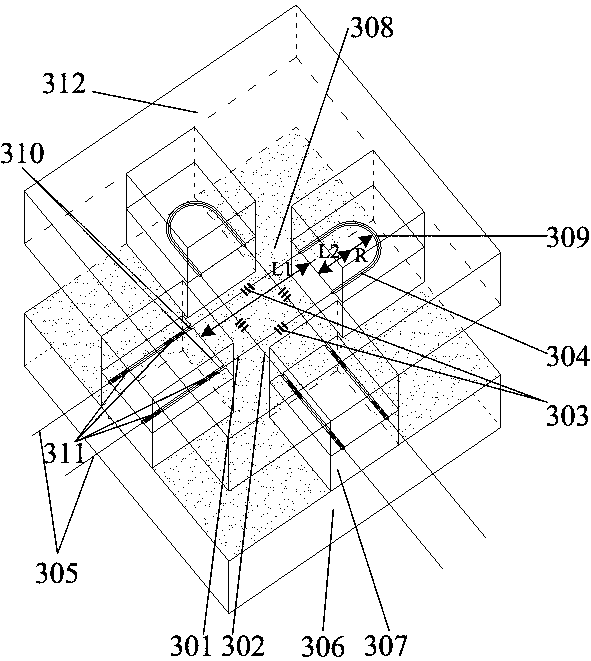

[0056] The second embodiment of the present invention is a two-dimensional optical fiber vector microphone probe with orthogonal directivity of "8" directivity used by a complete fiber optic vector microphone probe to directly measure the particle velocity U of the acoustic signal vector. Cascaded mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com