Steady test system and method for heat conduction coefficient and interface thermal resistance of radiation heat-dissipation correction-type aviation background material

A technology of background materials and radiation heat dissipation, which is applied in the field of steady-state testing of thermal and physical properties of materials, can solve problems such as difficult testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

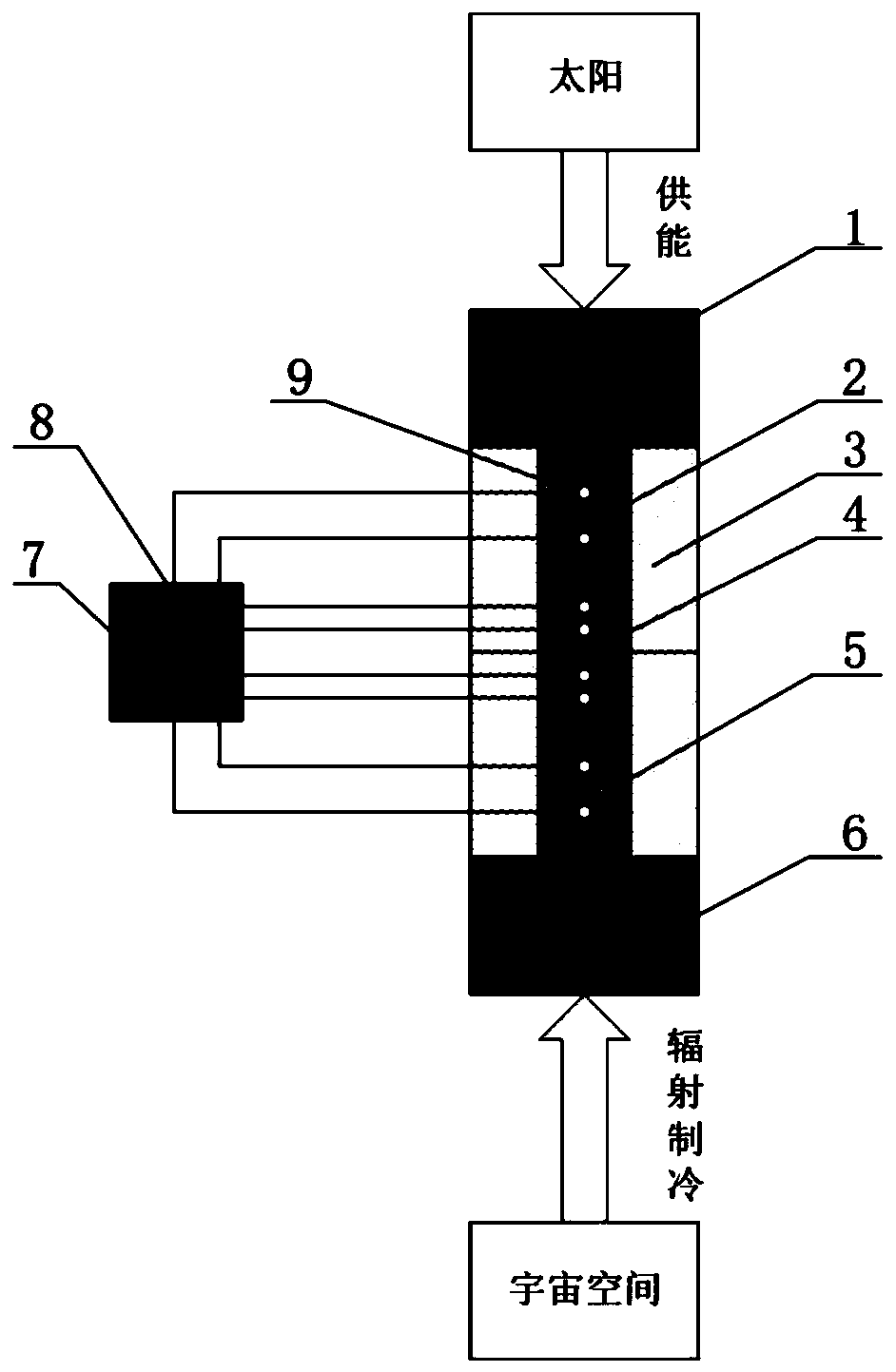

[0035] like figure 1 As shown, the steady-state test system for the thermal conductivity and interface thermal resistance of the radiation heat dissipation modified aviation background material of the present invention consists of a germanium solar absorbing plate heat source 1, a hot-side aluminum alloy heat flow meter 2, a radiation protection layer 3, and a cold-side aluminum alloy It is composed of heat flow meter 5, radiative cooling plate cold source 6, solar battery 7, data acquisition instrument 8, and temperature sensor 9. The hot-side aluminum alloy heat conductor 2 and the cold-side aluminum alloy heat conductor 5 are structurally coaxial, and the heat source 1 of the germanium solar absorbing plate and the hot-side aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com