Safety and reliability evaluation method for flue gas online monitoring system with consideration of common cause failure

A monitoring system and evaluation method technology, applied in the direction of measuring devices, analyzing gas mixtures, gas analyzers, etc., can solve the problems of complex analysis process, lack of clarity and intuition, and achieve easy parameter estimation and qualitative analysis Or quantitative analysis, the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The technical solutions in the embodiments of the present invention will be described clearly and in detail below with reference to the drawings in the embodiments of the present invention. The described embodiments are only some of the embodiments of the invention.

[0059] The technical scheme that the present invention solves the problems of the technologies described above is:

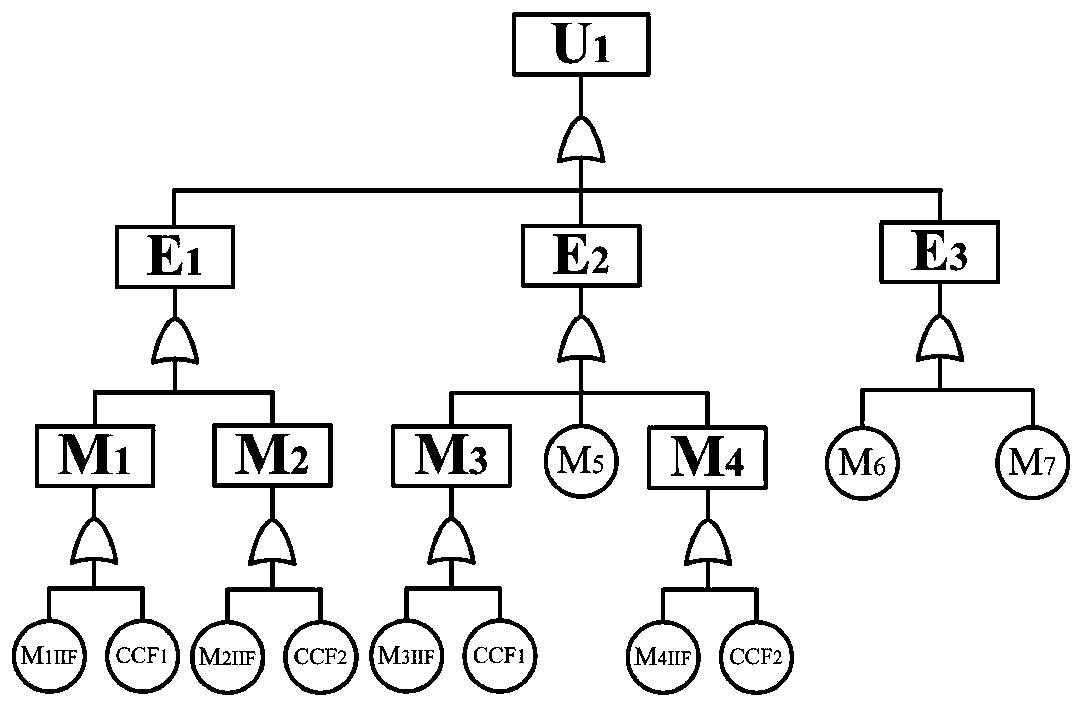

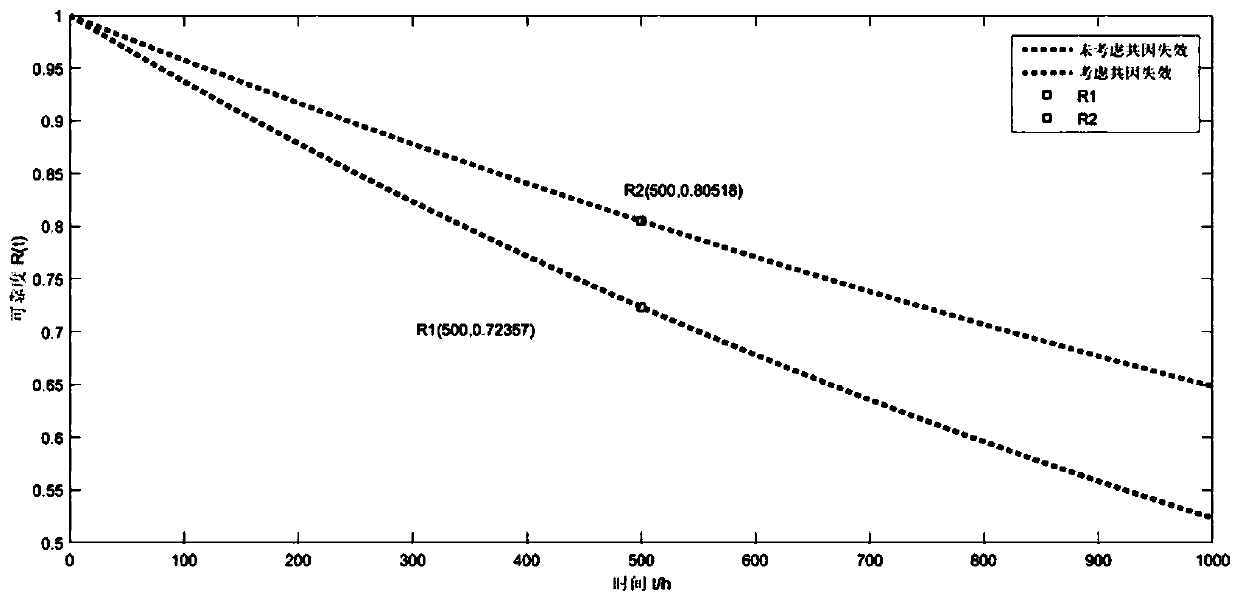

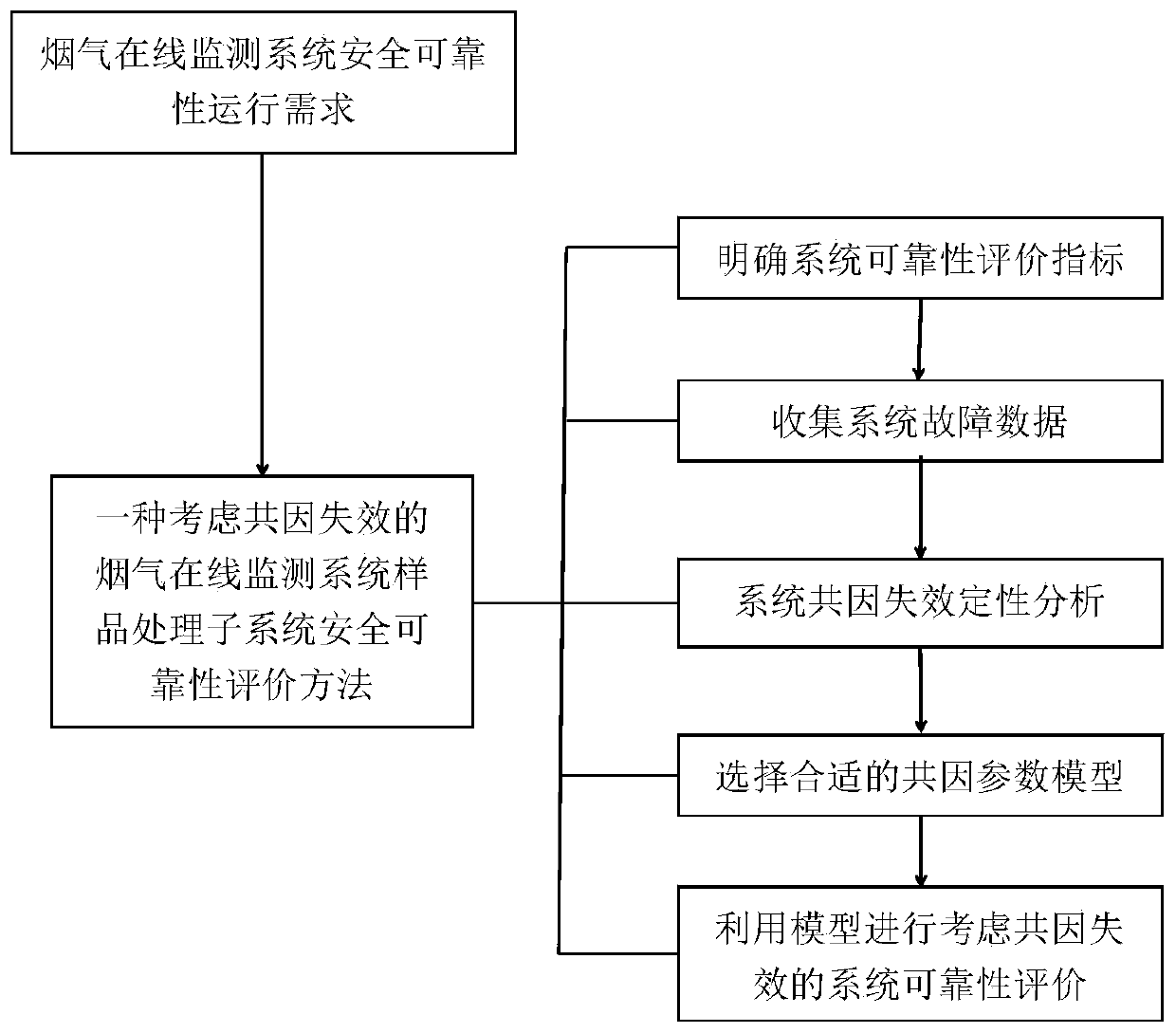

[0060] The invention evaluates the safety and reliability of the sample processing sub-system of the flue gas on-line monitoring system, and improves the rationality of the reliability evaluation by considering the common cause failure when analyzing the failure cause. Firstly, the relevant indexes of the reliability evaluation of the present invention are clarified; secondly, the failure data of the system are collected, and the failure modes are analyzed. Then choose the fault tree analysis method to model the fault tree considering the common cause failure of the sample processing subsys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com