Hot-rolled strip steel surface defect detection method based on deep learning

A technology for hot-rolled strip and defect detection, applied in optical testing defect/defects, measuring devices, scientific instruments, etc., can solve problems such as difficulty in meeting inspection needs, large differences in shape and size, and insufficient small targets

- Summary

- Abstract

- Description

- Claims

- Application Information

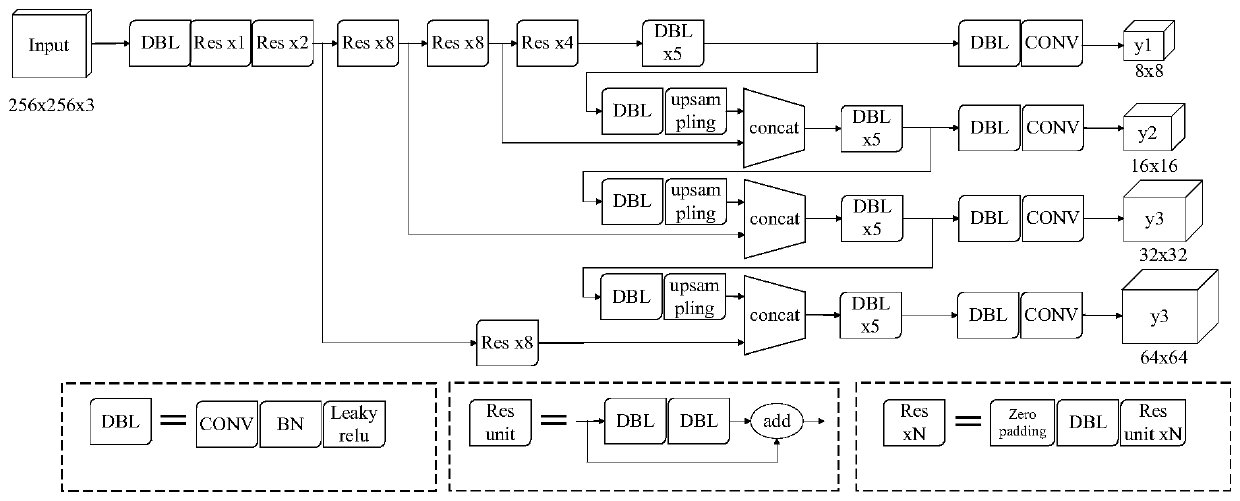

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Use the keras framework to build the model, and use opencv (an open source computer vision library) to preprocess the image. The hardware configuration used in the experiment is Core i7-9700K processor, RTX 2080Ti graphics card, and the software environment is CUDA10.0 and cuDNN9.1.

[0041] A kind of hot-rolled steel strip surface defect detection method based on the improved YOLOv3 algorithm of the present invention, it comprises:

[0042] Step 1: Build a data set, mark all pictures, and record the location and category information of all defective objects. Divide the data set into training set and test set, use the training set for training, and use the test set to verify the detection accuracy and speed of the model.

[0043] Take the NEU-DET data set released by Northeastern University as an example. The data set collects 300 pictures of 6 types of steel strip surface defects, and the picture size is 200x200. The defects are rolled-in scale (RS), plaques (patches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com