Single-phase three-level power factor correction rectifier based on symmetrical four ports

A power factor correction, four-port technology, applied in the field of single-phase three-level power factor correction rectifiers, can solve the problems of voltage and current power factor, low current power factor, etc., and achieve the effect of improving short-term power supply demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

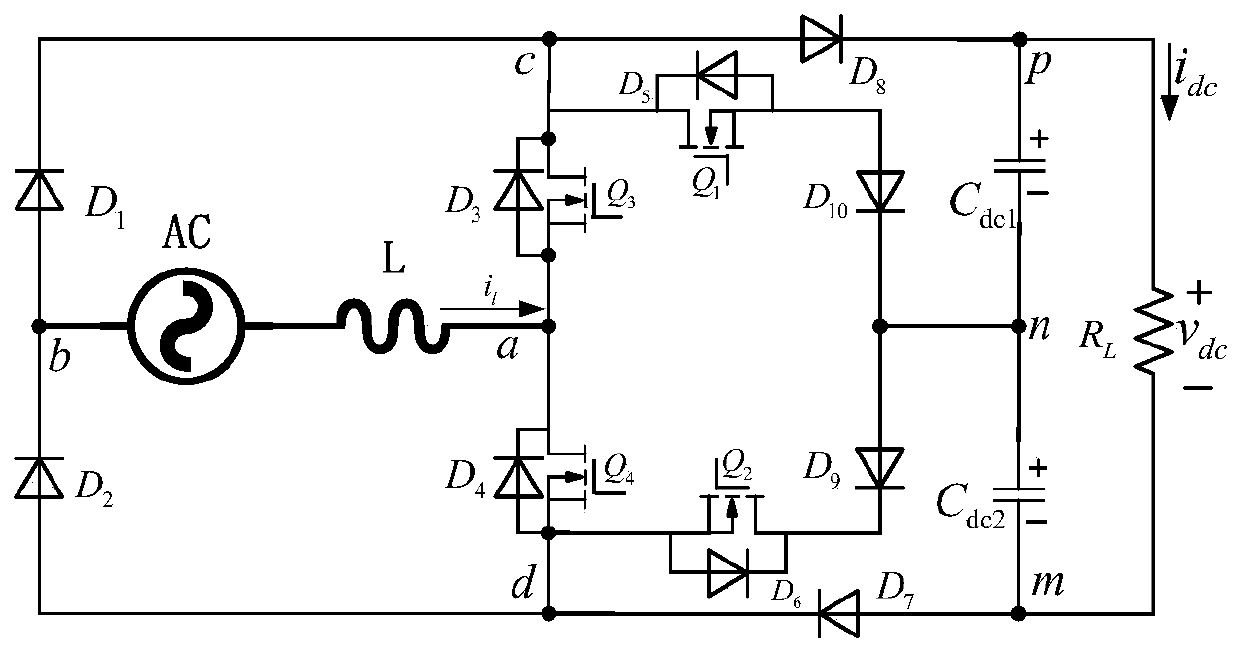

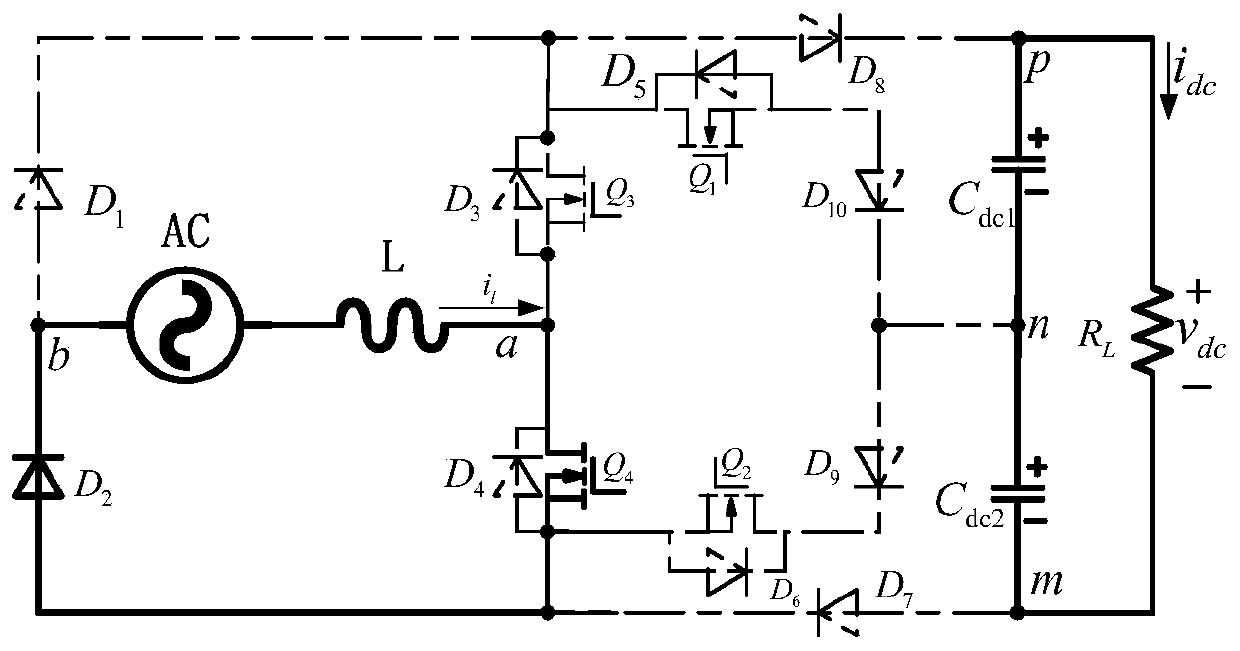

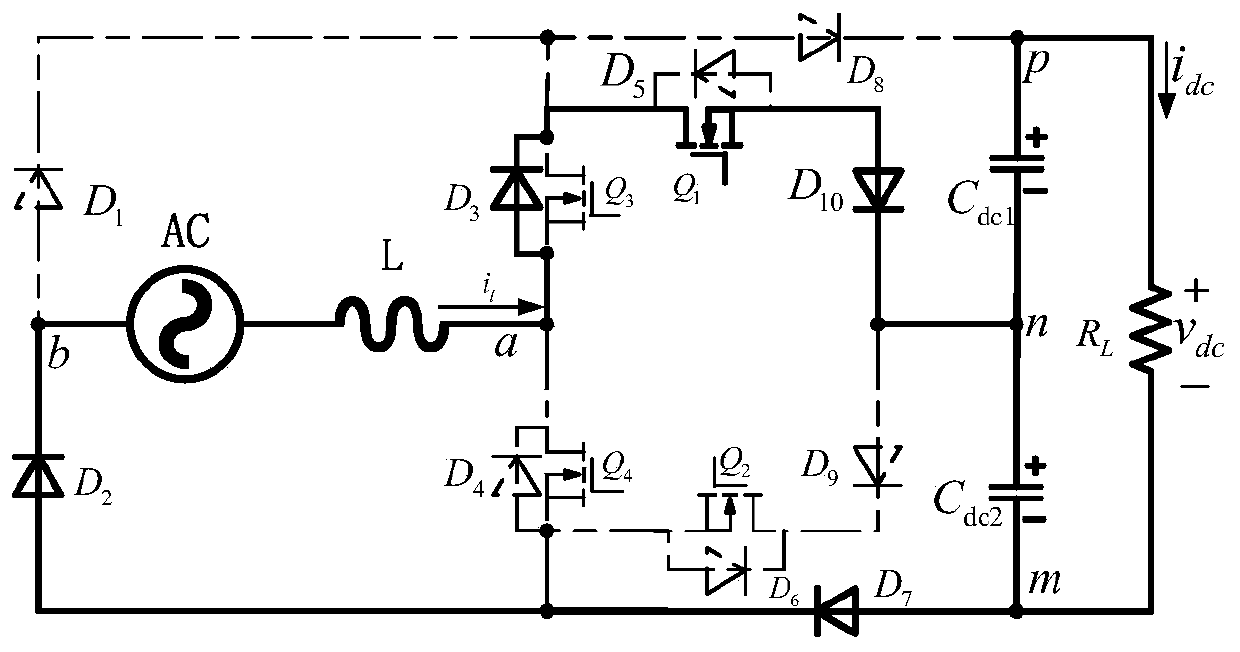

[0058] Such as figure 1 As shown, based on asymmetric four-port single-phase three-level power factor correction rectifier, including:

[0059] Including AC power supply, inductor L, switch tube Q 1 , Q 2 , Q 3 , Q 4 , Diode D 1 、D 2 、D 7 、D 8 、D 9 、D 10 , capacitance C dc1 、C dc2 ;

[0060] The AC side of the AC power supply is connected to the diode D 1 anode, diode D 2 a cathode connected to the nodes forming terminal b;

[0061] The other side of the AC power supply AC is connected to one end of the inductor L, and the other end of the inductor L is connected to the switch tube Q 3 Source, switch tube Q 4 Drains connected to nodes forming terminal a;

[0062] Switch tube Q 3 The drains are connected to the diode D 1 cathode, diode D 8 an anode, the junction of which constitutes terminal c;

[0063] Switch tube Q 4 The source is connected to the diode D respectively 2 anode, diode D 7 a cathode connected to the nodes forming terminal d;

[0064] Dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com