Rotational symmetrical and non-symmetrical plastic forming machine

A molding machine, plastic technology, used in forging presses, forging presses, transportation and packaging, etc., can solve problems such as difficult plastic molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

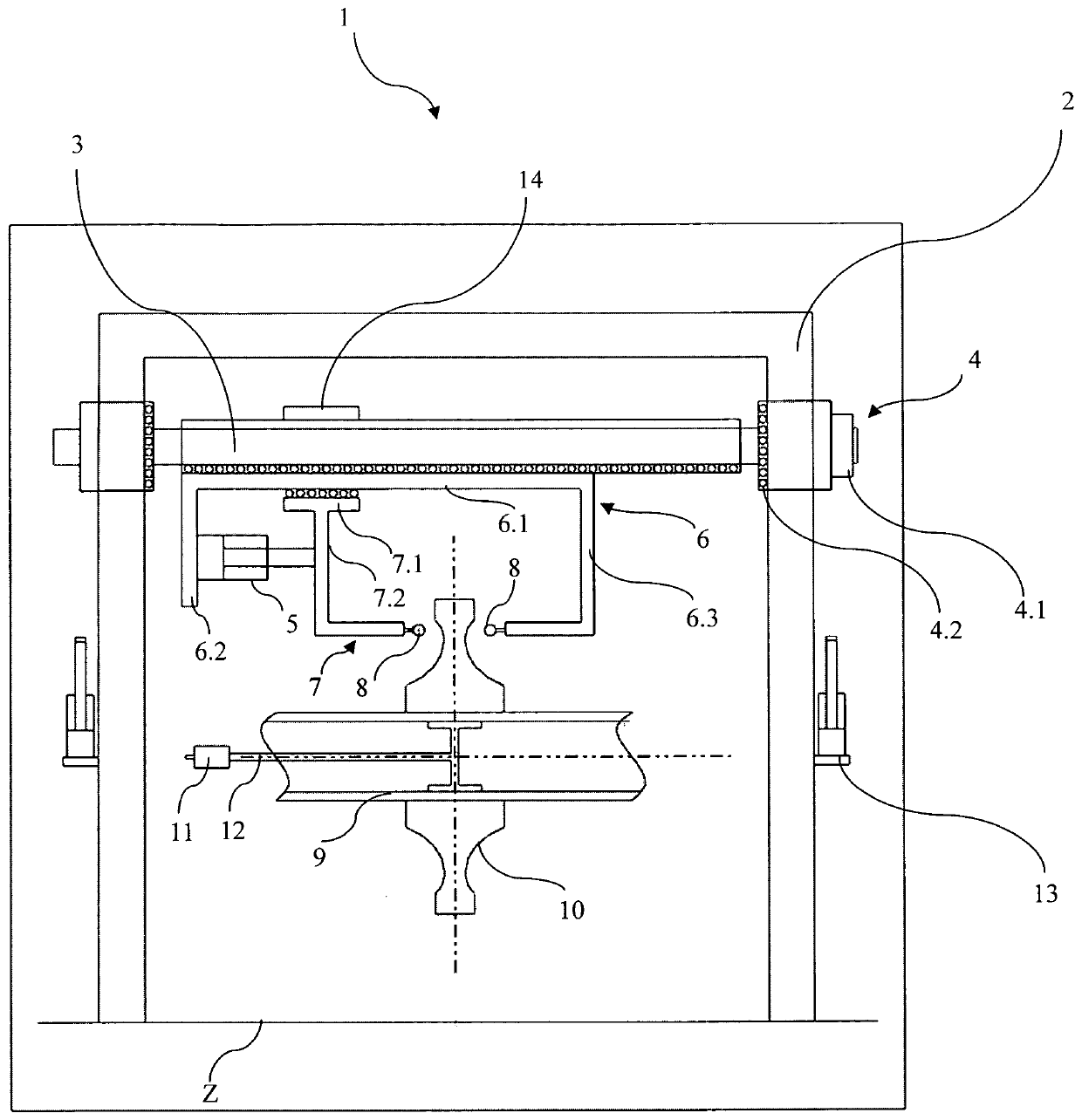

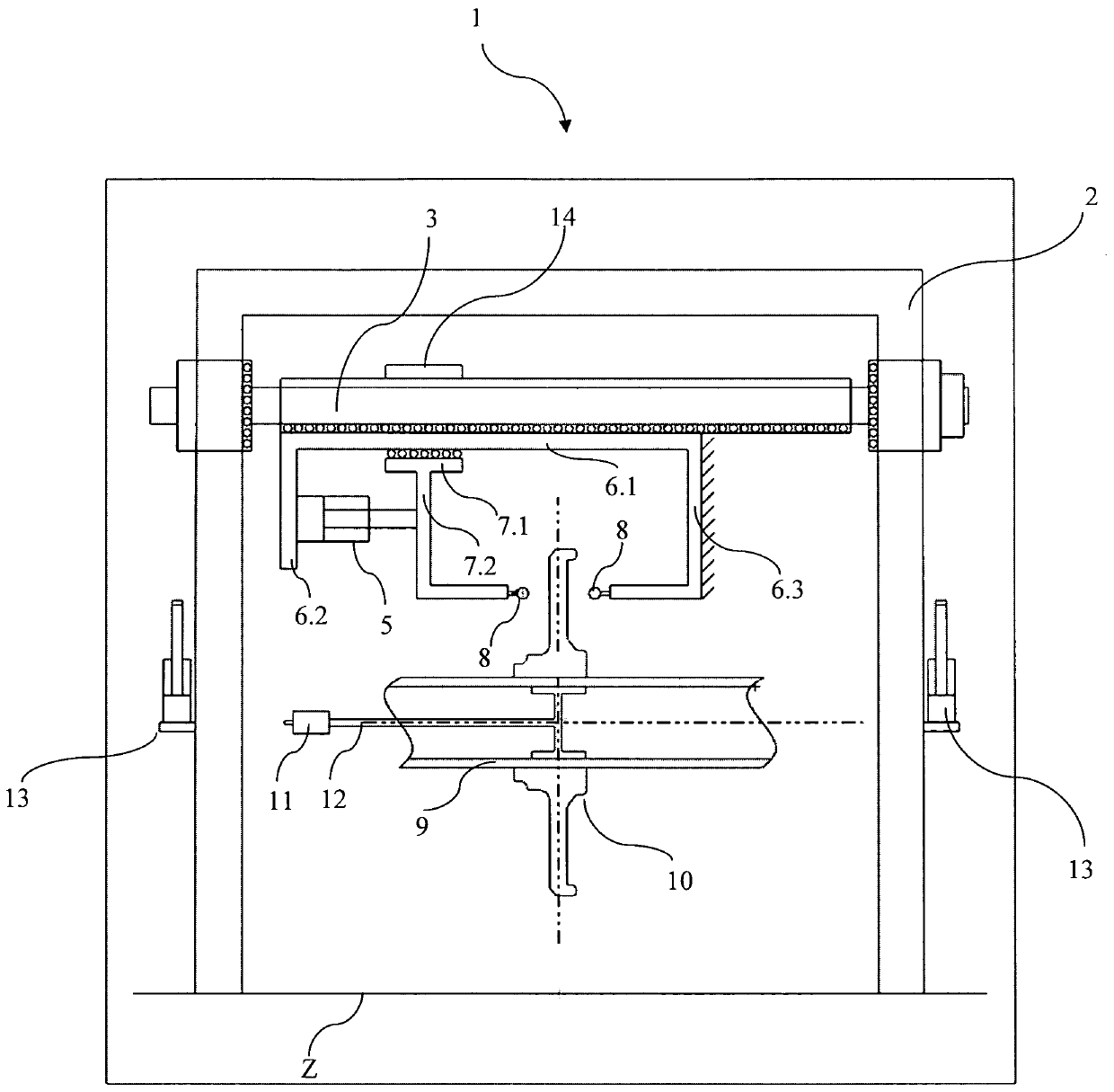

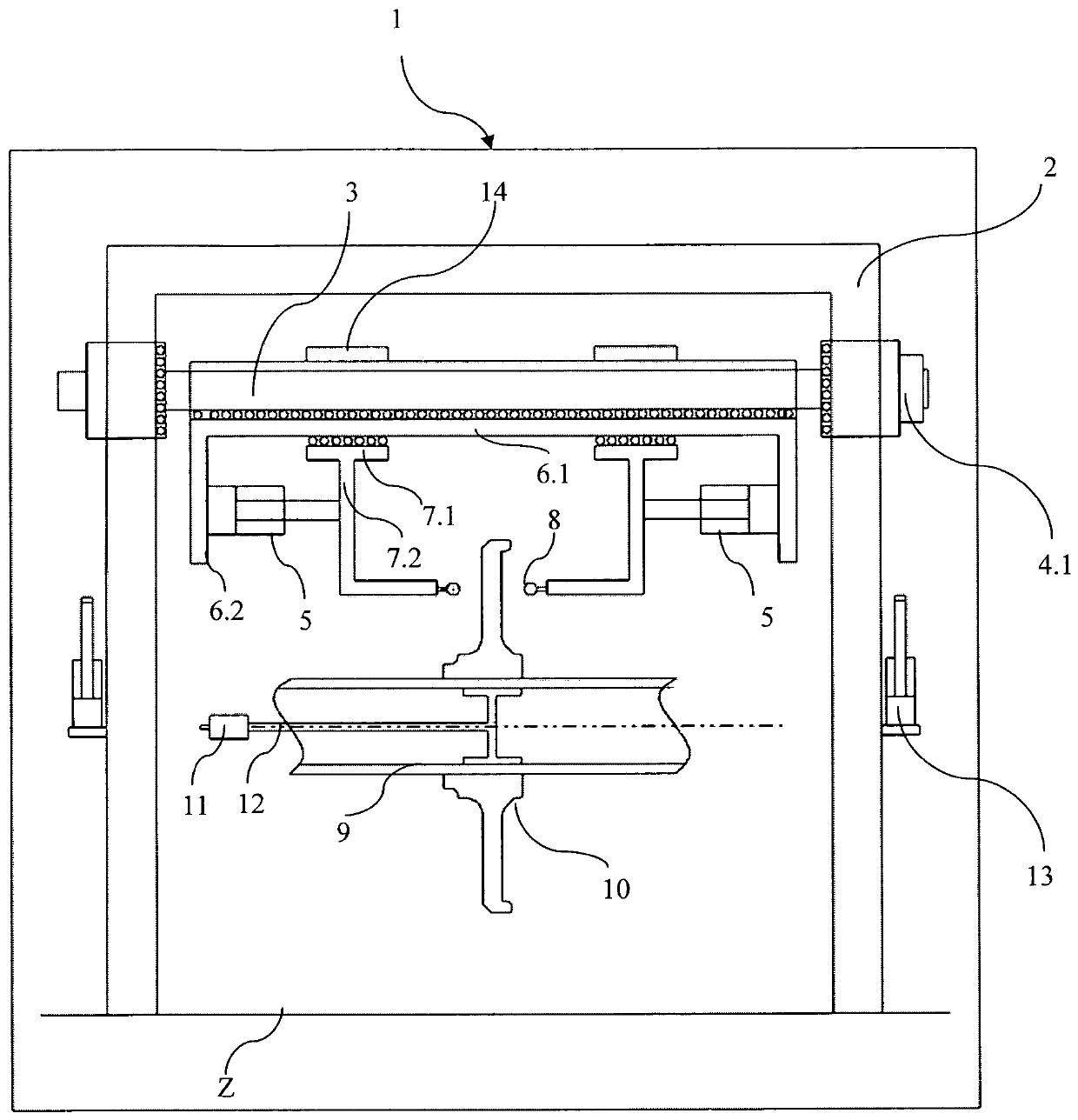

[0012] Components shown in the drawings are given reference numbers as follows:

[0013] 1. Plastic forming machine

[0014] 2. Fixed column

[0015] 3. Movable column

[0016] 4. Linear moving system

[0017] 4.1 Linear motor

[0018] 4.2 The first linear sliding bearing

[0019] 5. Actuator

[0020] 6. The first pressure rod

[0021] 6.1. First arm

[0022] 6.2. Second arm

[0023] 6.3. Third arm

[0024] 7. Second pressure rod

[0025] 7.1. Fourth arm

[0026] 7.2. Fifth arm

[0027] 8. Contact end

[0028] 9. Shaft

[0029] 10. Raw materials

[0030] 11. Electric motor

[0031] 12. Handle

[0032] 13. Stop piston

[0033] 14. The second linear sliding bearing

[0034] 15. Control system

[0035] Z. Ground

[0036] - a rotational plastic molding machine 1 for processing materials with a symmetrical or asymmetrical final geometry, essentially comprising at least one fixed column 2,

[0037] - a movable column 3 positioned such that the movable column wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com