Rolling process of bismuth-containing free cutting steel

A technology of process and process, applied in the field of rolling production process of easy-cut steel, to achieve good organization, avoid steel stamping accidents, excellent structure and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

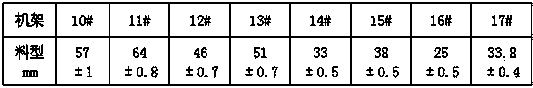

[0026] Example 1. In this embodiment, a round bismuth-containing free-cutting steel bar with a diameter of 22 mm is rolled.

[0027] Billet size: 150×150mm continuous casting billet, billet length 3m. Rolling is carried out through the rough rolling unit, the intermediate rolling unit, the pre-finishing rolling unit and the finishing rolling unit, and the entire continuous rolling unit is arranged alternately. The prepared bismuth-containing free-cutting steel continuous casting billet is sent to a continuous heating furnace for heating, and the heating temperature is controlled at 1150 to 1230°C, and it is discharged into the rolling process. Before entering the rough rolling mill, high-pressure water is used to descaling the surface of the rolling piece to break all the oxide scales on the surface of the billet and remove the surface oxide layer. The pressure of the high-pressure water is 18-20 MPa.

[0028] In order to achieve uniform deformation of free-cutting steel, the sta...

Embodiment 2

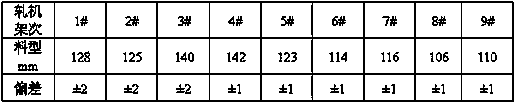

[0034] Example 2. In this embodiment, S29mm hexagonal free-cutting steel bars containing bismuth are rolled.

[0035] Billet size: 150×150mm continuous casting billet, billet length 3m. Rolling is carried out through the rough rolling unit, the intermediate rolling unit, the pre-finishing rolling unit and the finishing rolling unit, and the continuous rolling unit is arranged alternately. The prepared bismuth-containing free-cutting steel continuous casting billet is sent to a continuous heating furnace for heating, and the heating temperature is controlled at 1150-1230°C, and then it is discharged into the rolling process. Before entering the rough rolling, high-pressure water is used to descaling the surface of the rolling piece, all the oxide scale on the surface of the billet is broken, and the surface oxide layer is removed. The pressure of the high-pressure water is 18-20 MPa.

[0036] The rough rolling mill adopts a combination of box-square and rhombus-square pass systems...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com