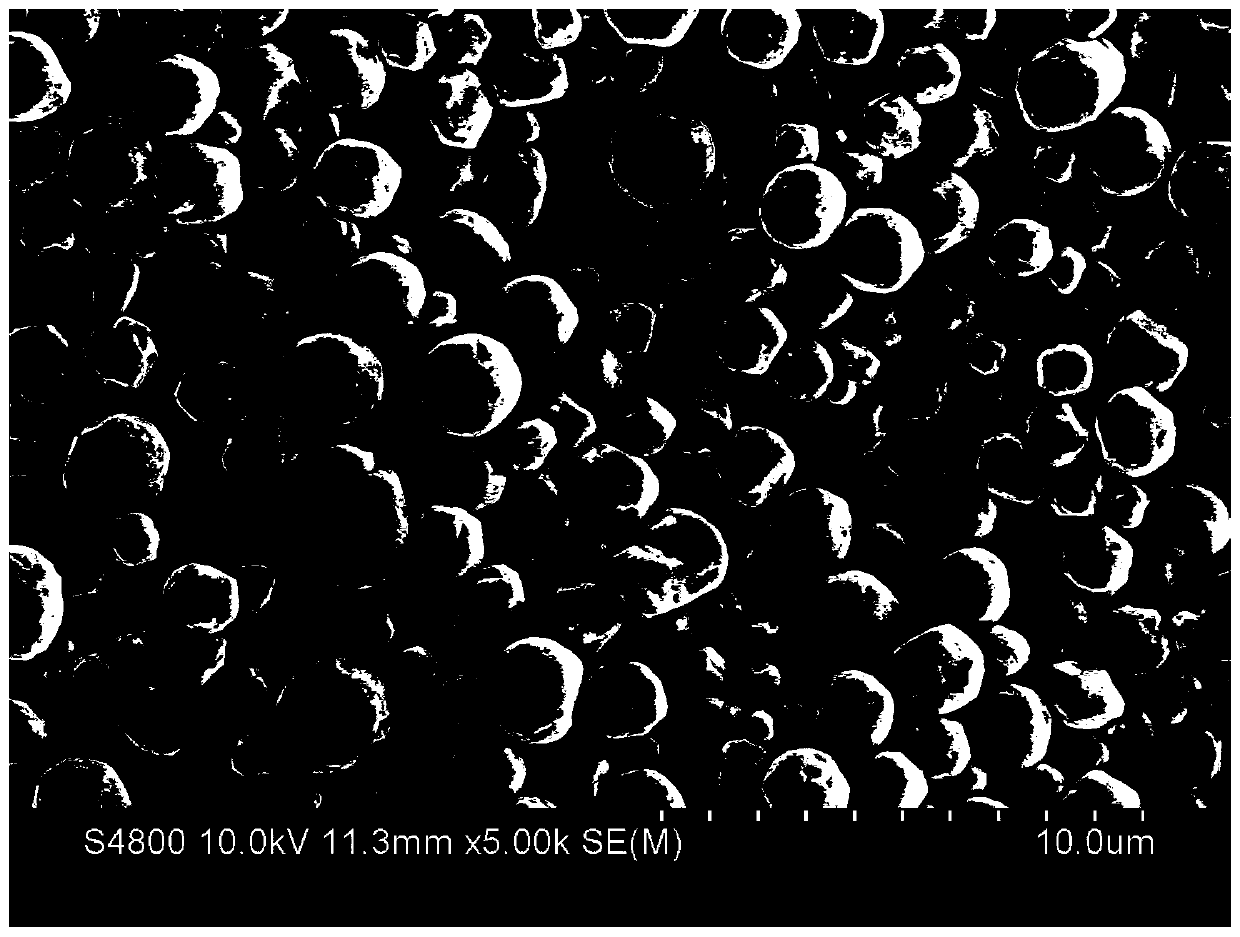

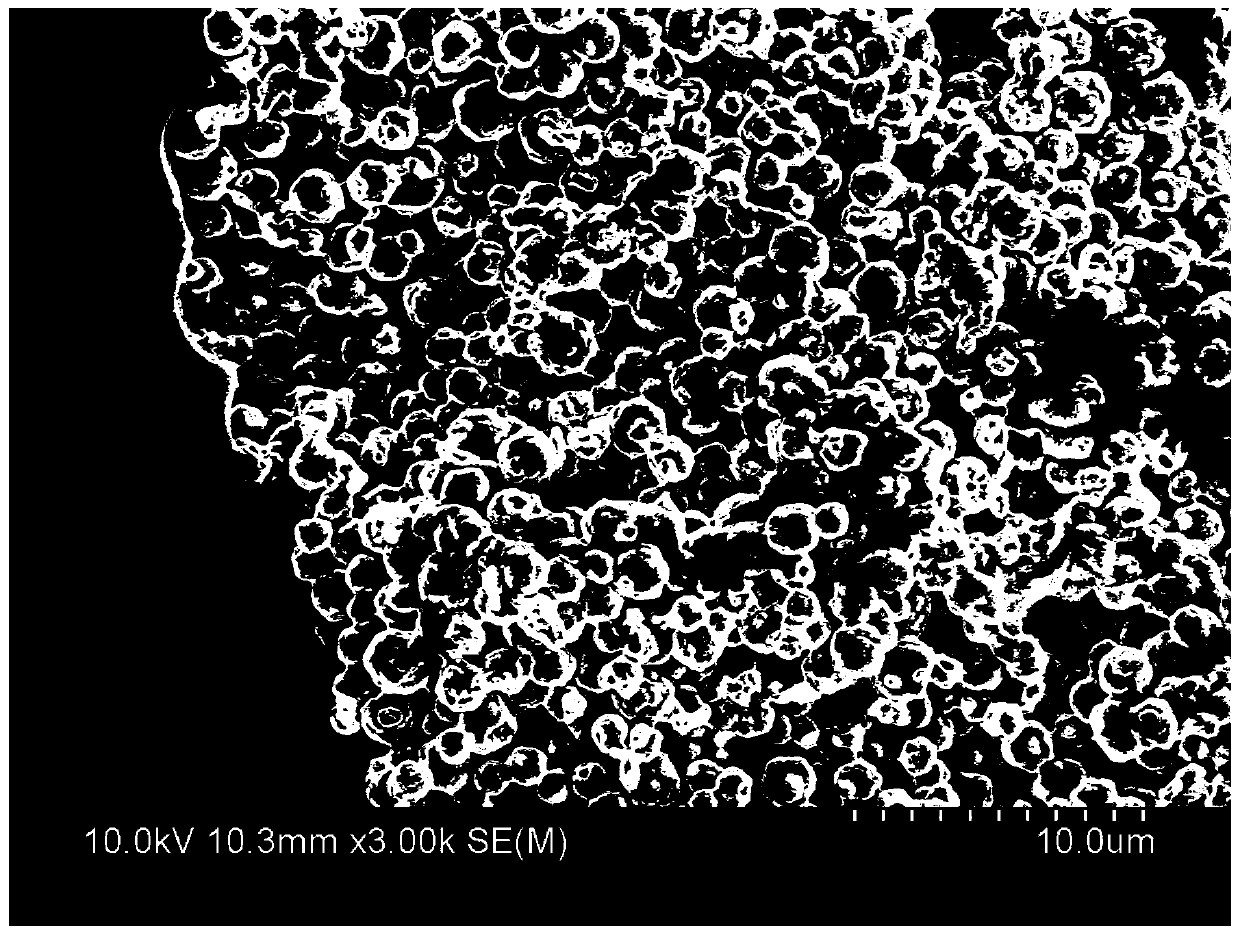

Preparation method of spheroidal silver powder

A silver powder and spherical technology, which is applied in the field of preparation of quasi-spherical silver powder, can solve the problems of continuity and uniformity of tension and instability, and achieve the effects of improving fluidity and filling performance, wide controllable range and wide window.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] A preparation method of spherical silver powder includes the following steps:

[0069] Step 1: Solution preparation, prepare silver nitrate solution A, reducing agent solution B, regulator solution C and dispersant solution D respectively;

[0070] Step 2: Reduction reaction

[0071] Under high-speed stirring, add a quantitative regulator solution C to the reducing agent solution B, and then quickly add the silver nitrate solution A to the reducing agent solution B at a certain flow rate through a flowmeter. In the silver nitrate solution A and the regulator solution C Before or after the addition, quickly add the dispersant solution D to the reducing agent solution B, adjust the temperature after the addition, and continue to stir and react for 15-30 minutes;

[0072] Step 3: Chemical modification of silver powder

[0073] After the above step 2 reduction reaction is completed, the supernatant after the reaction is removed by sedimentation, and the remaining part is transferred...

Embodiment 1

[0085] A preparation method of spherical silver powder includes the following steps:

[0086] Step 1: Solution preparation

[0087] Preparation of silver nitrate solution

[0088] Dissolve 10kg of silver nitrate in 40L of deionized water and control the temperature to 32.0~35.0℃ to prepare silver nitrate solution A;

[0089] Preparation of reducing agent solution

[0090] Dissolve 6.4kg of ascorbic acid in 220L of deionized water and control the temperature to 32.0~35.0℃ to prepare reducing agent solution B;

[0091] Preparation of conditioner solution

[0092] Prepare 2 kg of nitric acid with a mass concentration of 10% to prepare regulator solution C;

[0093] Preparation of dispersant solution

[0094] Dissolve 50g of gelatin in 2L of deionized water and control the temperature to 50-60°C to prepare dispersant solution D;

[0095] Step 2: Reduction reaction

[0096] Under high-speed stirring, quickly add the conditioner solution C to the reducing agent solution B, and then add the silver n...

Embodiment 2

[0105] A preparation method of spherical silver powder includes the following steps:

[0106] Step 1: Solution preparation

[0107] Preparation of silver nitrate solution

[0108] Dissolve 10kg of silver nitrate in 30L of deionized water and control the temperature to 41.0~43.0℃ to prepare silver nitrate solution A;

[0109] Preparation of reducing agent solution

[0110] Dissolve 4.5kg of ascorbic acid and 1.5kg of glucose in 200L of deionized water and control the temperature to 41.0~43.0℃ to prepare reducing agent solution B;

[0111] Preparation of conditioner solution

[0112] Prepare 3 kg of ammonia water with a mass concentration of 8% to prepare regulator solution C;

[0113] Preparation of dispersant solution

[0114] Dissolve 30g of gelatin in 2L of deionized water and control the temperature at 50-52°C to prepare dispersant solution D1. Dissolve 30g of polyvinyl alcohol in 2L of deionized water and control the temperature at 50-52°C to prepare dispersant solution D2;

[0115] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com