Automatic grinding rust removal device for steel pipe outer wall

A steel pipe, automatic technology, applied in the direction of grinding drive device, grinding machine, grinding frame, etc., can solve the problems of low rust removal efficiency, easy surface moisture, hidden dangers, etc., to achieve simple structure, reduce labor intensity, avoid channeling moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

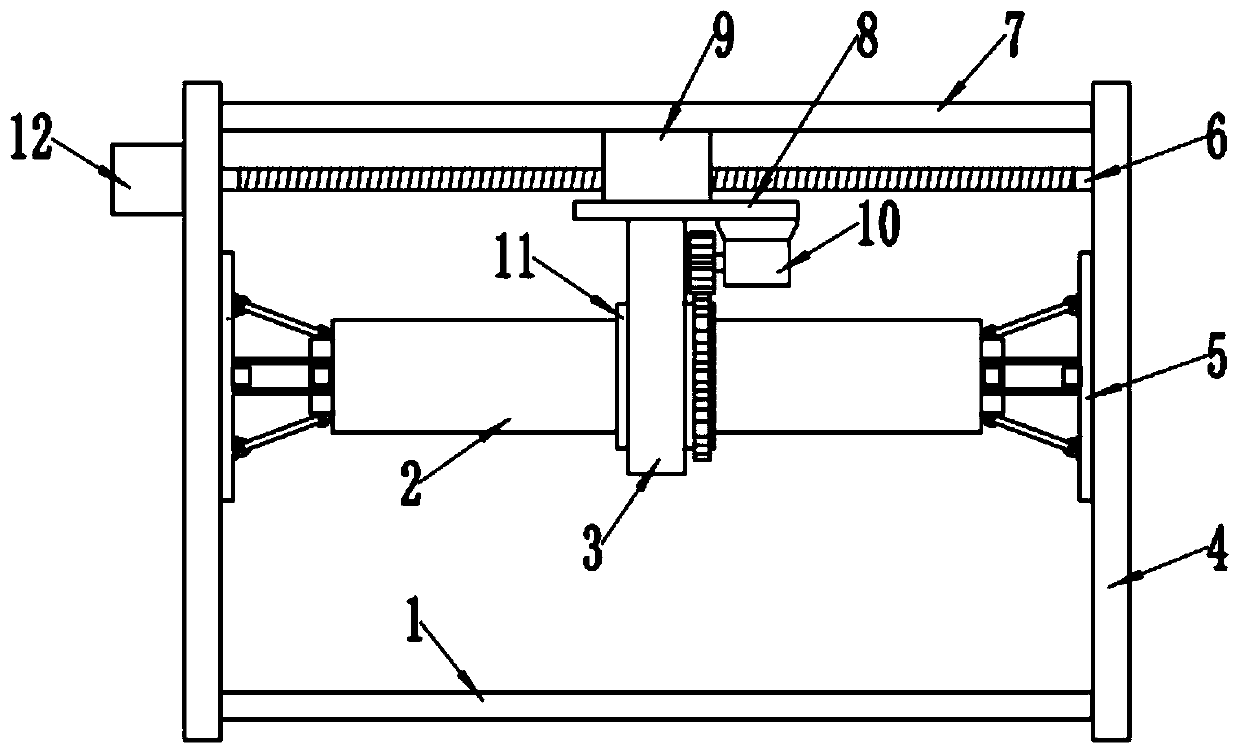

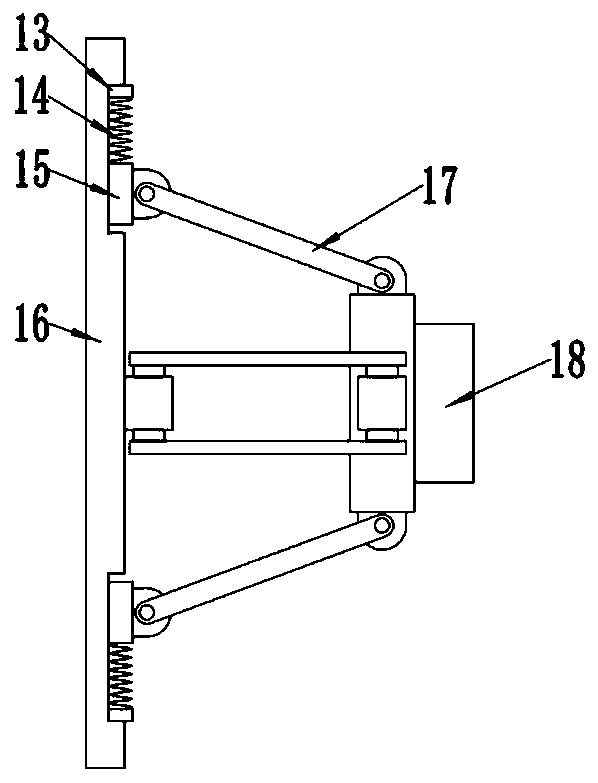

[0026] see Figure 1~3 , in an embodiment of the present invention, an automatic grinding and derusting device for the outer wall of a steel pipe includes a base 1, a grinding mechanism 3 and a fixing mechanism 5; A top plate 7 is fixedly installed on the top of the top plate 7, and a first screw rod 6 is arranged below the top plate 7. The left and right sides of the first screw rod 6 are respectively rotatably connected with two side plates 4, and the first screw rod 6 is threadedly connected with a first screw sleeve. 9. The upper side of the first screw sleeve 9 is slidingly connected with the top plate 7, and the rotation of the first screw rod 6 drives the first screw sleeve 9 to slide left and right at the bottom of the top plate 7;

[0027] Specifically, in this embodiment, the outer side of the side plate 4 is fixedly installed with a first rotating motor 12 that drives the first screw rod 6 to rotate;

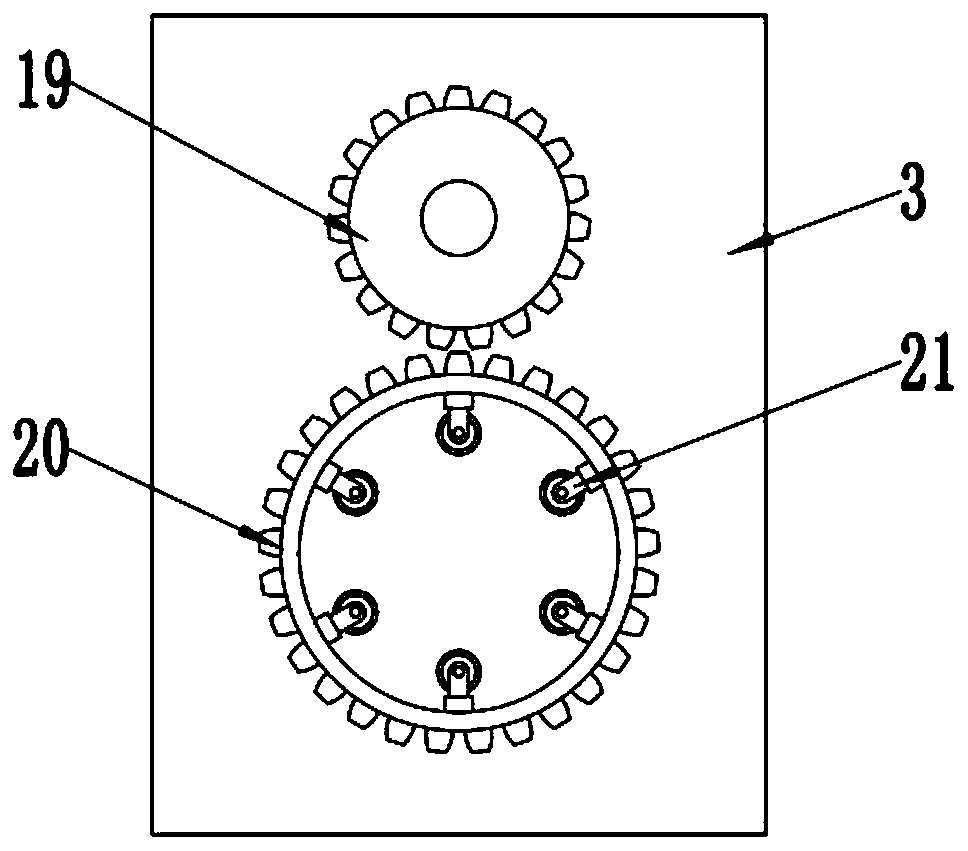

[0028] The grinding mechanism 3 is fixedly installed under the ...

Embodiment 2

[0032] see Figure 1~3 , in an embodiment of the present invention, an automatic grinding and derusting device for the outer wall of a steel pipe includes a base 1, a grinding mechanism 3 and a fixing mechanism 5; A top plate 7 is fixedly installed on the top of the top plate 7, and a first screw rod 6 is arranged below the top plate 7. The left and right sides of the first screw rod 6 are respectively rotatably connected with two side plates 4, and the first screw rod 6 is threadedly connected with a first screw sleeve. 9. The upper side of the first screw sleeve 9 is slidingly connected with the top plate 7, and the rotation of the first screw rod 6 drives the first screw sleeve 9 to slide left and right at the bottom of the top plate 7;

[0033] Specifically, in this embodiment, the outer side of the side plate 4 is fixedly installed with a first rotating motor 12 that drives the first screw rod 6 to rotate;

[0034]The grinding mechanism 3 is fixedly installed under the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com