Grabbing industrial robot for complex workpiece matching and positioning

A technology for industrial robots and complex workpieces, used in manipulators, manufacturing tools, program-controlled manipulators, etc., to increase structural rigidity, improve grasping accuracy, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

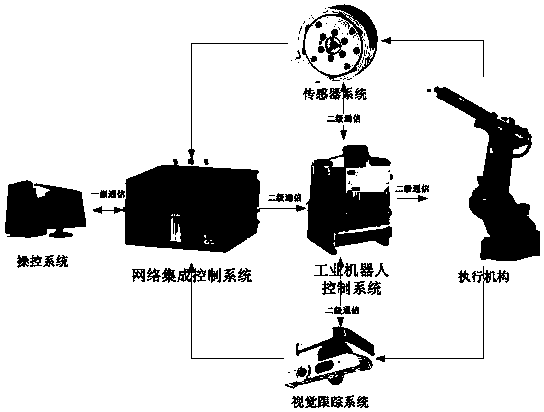

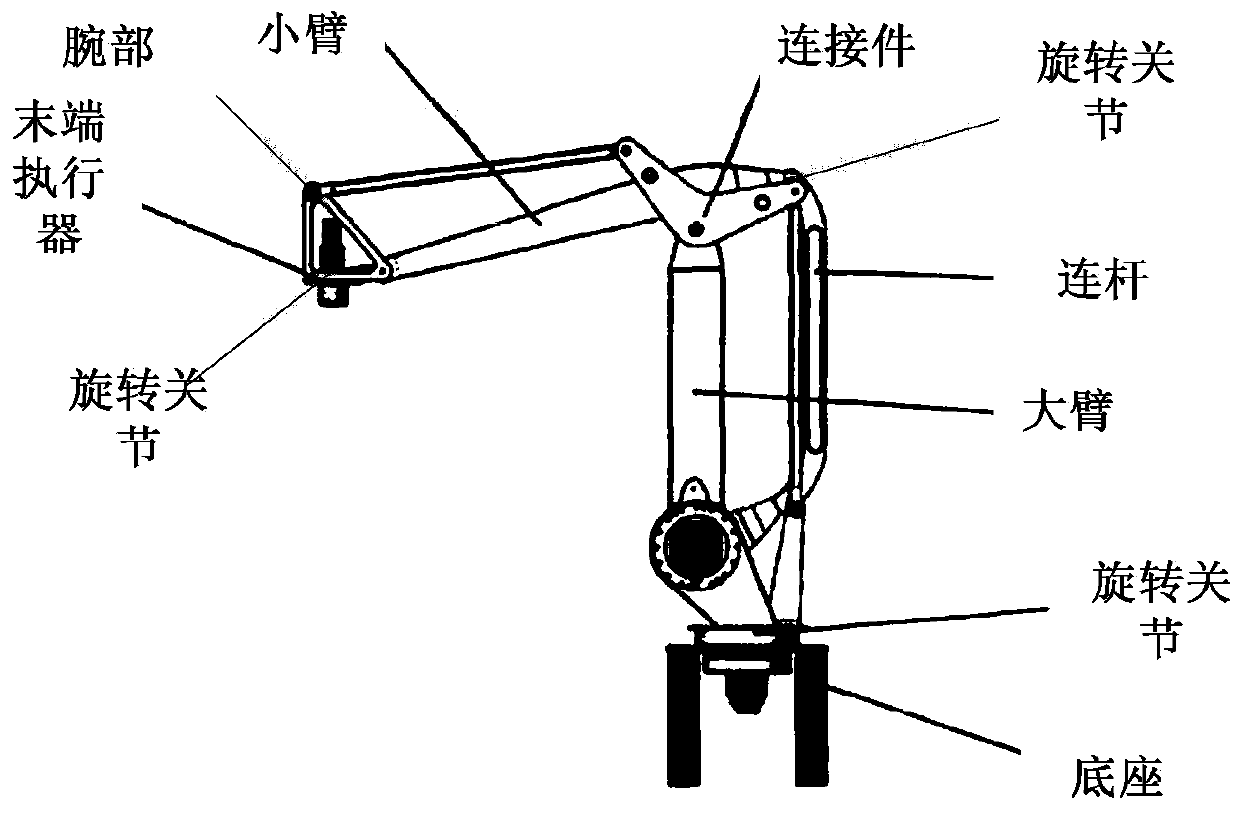

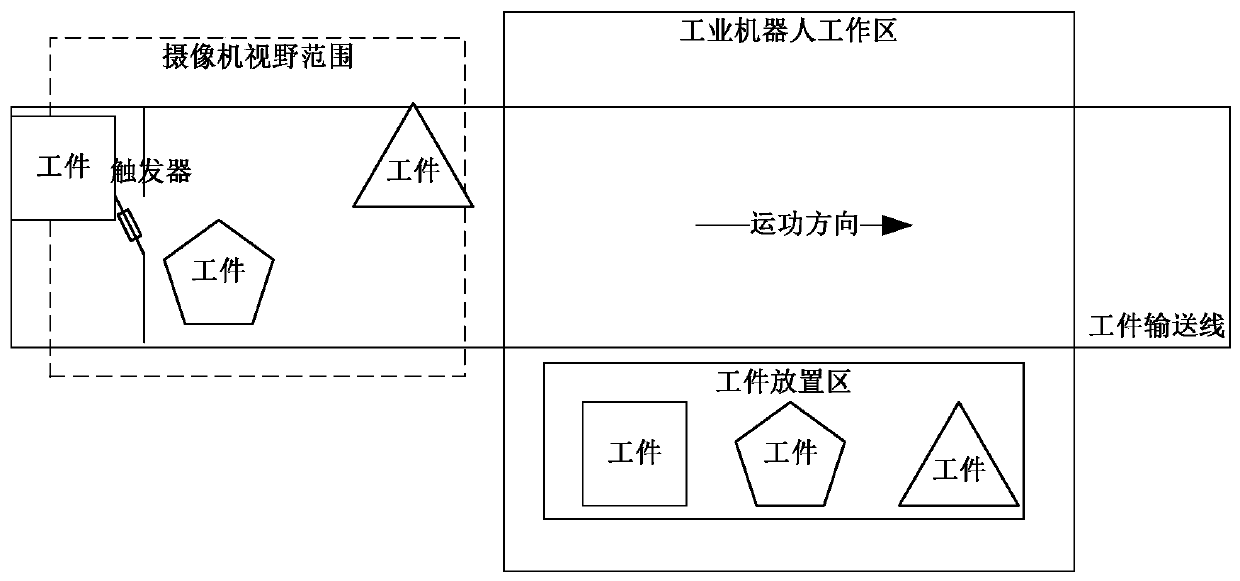

[0027] A grasping industrial robot for complex workpiece matching and positioning, including an industrial robot control system, a sensor system, a control system, a network integrated control system, a visual tracking system, and an actuator, the sensor system is connected to the industrial robot control system,

[0028] The control system receives data from the sensor system and the visual tracking system through the network integrated control system and sends control instructions to the industrial robot control system. The industrial robot control system controls the actuator, and the sensor system is installed on the actuator to monitor the position and posture of the actuator in real time. , the sensor system and visual tracking system are also connected with the industrial robot control system for real-time feedback of the working status of the actuator and monito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com