Shield tunnel segment capable of being reinforced and preparing method thereof

A shield tunnel segment and segment technology, which is used in reinforcement molding, manufacturing tools, ceramic molding machines, etc., can solve the problems of poor durability and fire resistance of structural adhesives, decreased stiffness and bearing capacity, and heavy ring steel plates. Achieve the effect of improving compressive strength, tensile strength, and stress strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

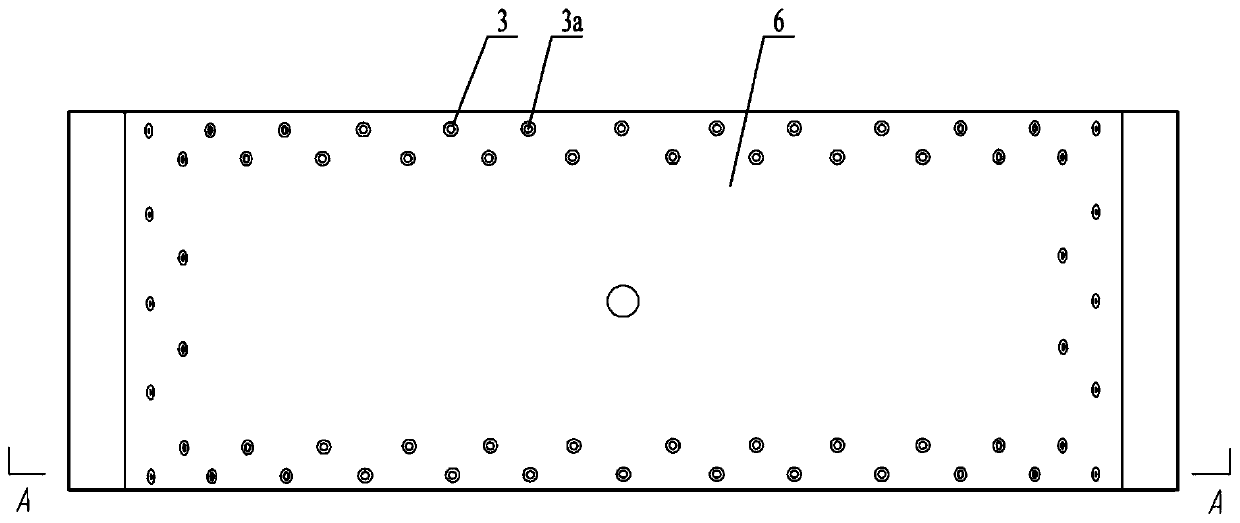

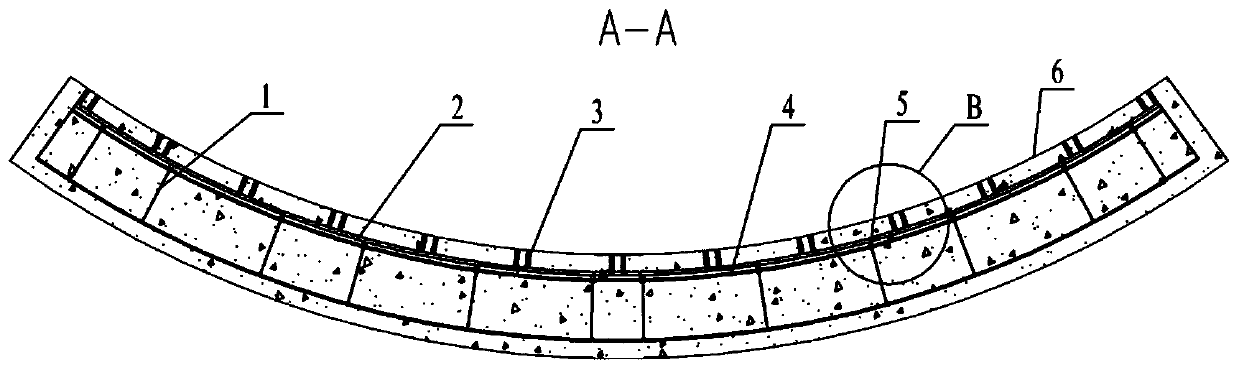

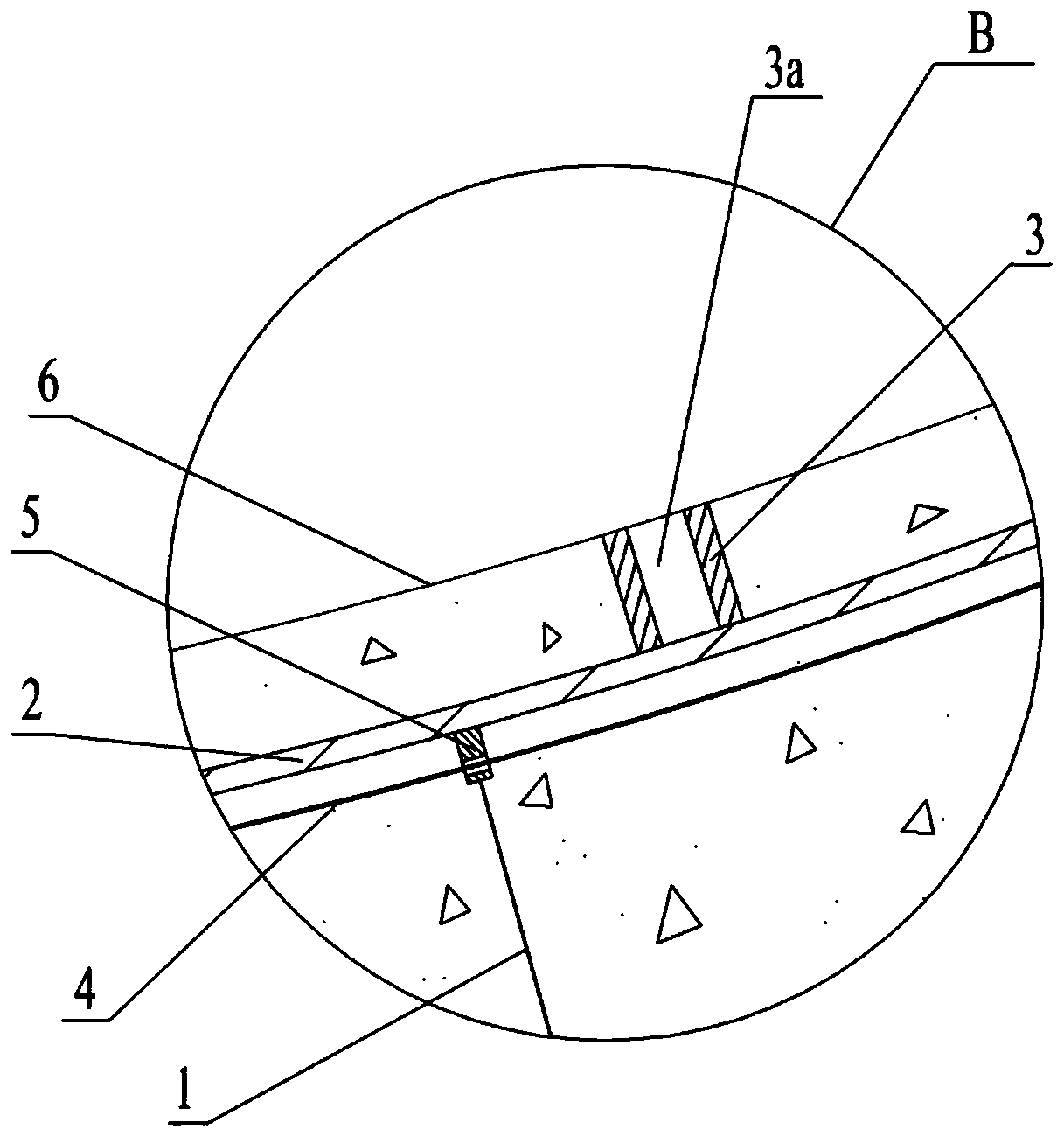

[0030] Figure 1-3 It is shown that a specific implementation of this embodiment is: a shield tunnel segment that can be reinforced, including an arc-shaped segment, and a steel mesh 1 embedded in the segment, characterized in that: the tube The inner arc side of the sheet is also pre-embedded with a bolted steel plate 2, and a bolted connector 3 is fixed, and the end of the bolted connector 3 is flush with the inner arc surface of the segment; the outer arc surface of the bolted steel plate 2 is fixed with The connecting steel bar 4 is bound on the reinforcing bar mesh 1 .

[0031] The bolted connectors 3 in this example are welded or threaded on the inner arc surface of the bolted steel plate 2; and the bolted connectors 3 are distributed around the inner arc surface of the bolted steel plate 2 in a double-row dislocation arrangement.

[0032] The bolt connection part 3 of this example is provided with an internally threaded connection hole, and a rubber plug 3a is plugged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com