A kind of nanocrystalline soft magnetic alloy, amorphous soft magnetic alloy and preparation method thereof

A nanocrystalline soft magnetic and soft magnetic alloy technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problems of low amorphous forming ability, poor high-frequency magnetic properties, etc., to improve the amorphous forming ability, Improved toughness, high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

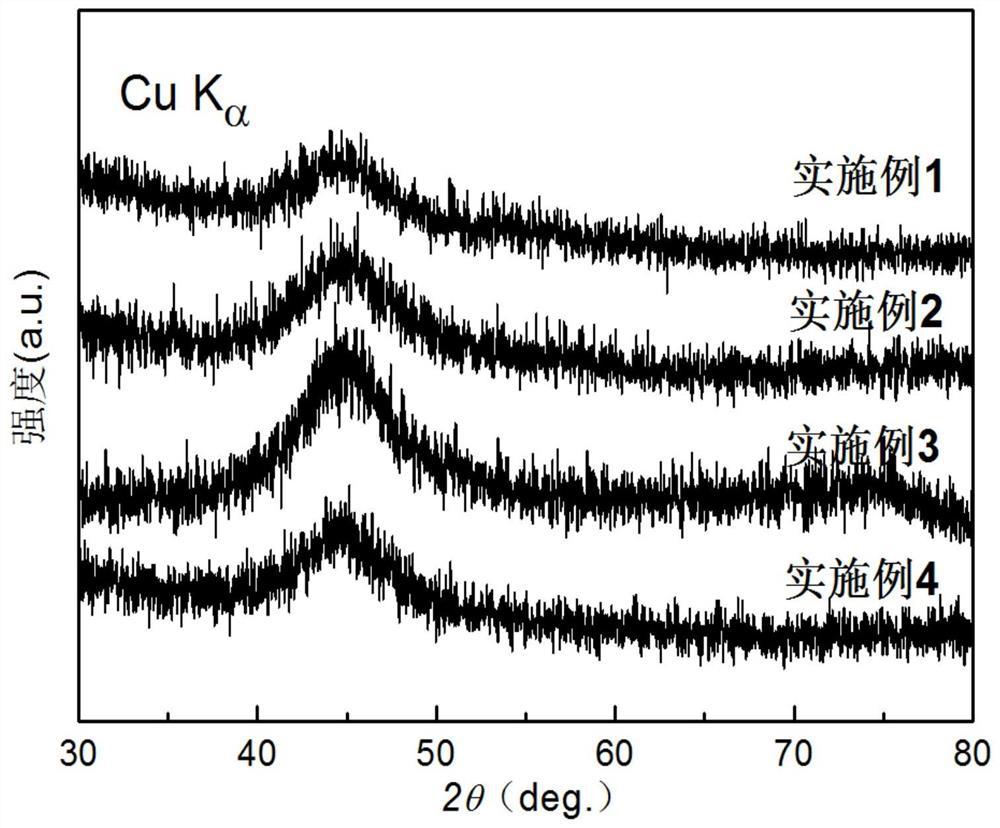

Embodiment 1

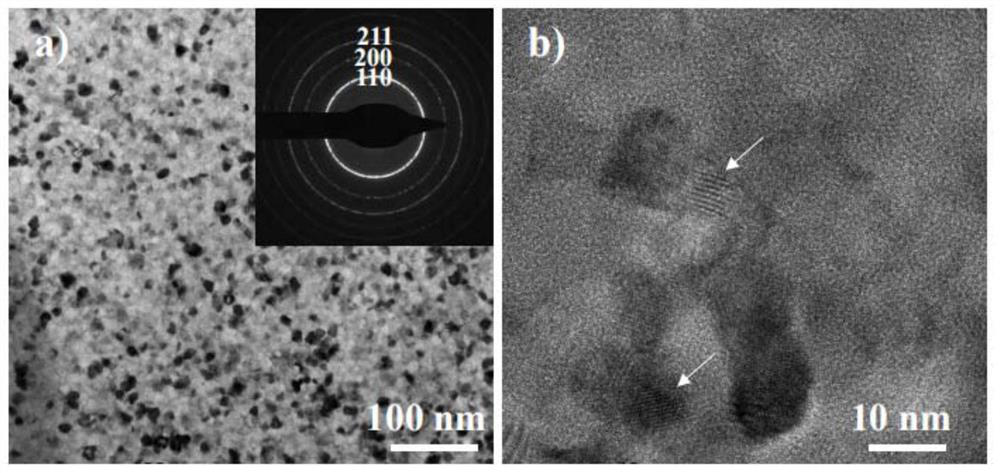

[0110] This embodiment provides a nanocrystalline soft magnetic alloy, its composition and atomic percentage are: Fe74.9at%, Mn 1at%, Cr 0.1at%, Cu 1at%, Si 18at%, B 4at%, Nb 1at %, that is, the molecular formula is Fe 74.9 mn 1 Cr 0.1 Cu 1 Si 18 B 4 Nb 1 .

[0111] The preparation method of nanocrystalline soft magnetic alloy comprises the following steps:

[0112] 1) Mix iron raw materials, manganese raw materials, chromium-containing alloy ingots, copper raw materials, silicon raw materials, boron-iron pre-alloyed ingots and niobium-iron pre-alloyed ingots according to the atomic percentage of the above-mentioned nanocrystalline soft magnetic alloy, and heat at 1200 ° C 60min, obtain high-temperature alloy molten steel;

[0113] 2) The high-temperature alloy molten steel is sprayed onto a 30m / s rotating copper roller through a nozzle of a certain shape by a melt quenching method to obtain an amorphous strip; the width of the amorphous strip is 100 mm, and the thickn...

Embodiment 2

[0116] This embodiment provides a nanocrystalline soft magnetic alloy, its composition and atomic percentage are: Fe74.5at%, Mn0.5at%, Cr1at%, Cu0.8at%, Si16.5at%, B5.5at% , Nb 1.2at%, that is, the molecular formula is Fe 74.5 mn 0.5 Cr 1 Cu 0.8 Si 16.5 B 5.5 Nb 1.2 .

[0117] The preparation method of nanocrystalline soft magnetic alloy comprises the following steps:

[0118] 1) Mix iron raw materials, manganese raw materials, chromium-containing alloy ingots, copper raw materials, silicon raw materials, boron-iron pre-alloyed ingots and niobium-iron pre-alloyed ingots according to the atomic percentage of the above-mentioned nanocrystalline soft magnetic alloy, and heat at 1400 ° C 20min, obtain high-temperature alloy molten steel;

[0119] 2) The high-temperature alloy molten steel is sprayed onto a 30m / s rotating copper roller through a nozzle of a certain shape by a melt quenching method to obtain an amorphous strip; the width of the amorphous strip is 10 mm, and ...

Embodiment 3

[0122] This embodiment provides a nanocrystalline soft magnetic alloy, its composition and atomic percentage are: Fe 74at%, Mn 2at%, Cu 1at%, Si 13at%, B 8at%, Nb 2at%, that is, the molecular formula is Fe 74 mn 2 Cu 1 Si 13 B 8 Nb 2 .

[0123] The preparation method of nanocrystalline soft magnetic alloy comprises the following steps:

[0124] 1) Mix iron raw materials, manganese raw materials, copper raw materials, silicon raw materials, boron-iron pre-alloyed ingots and niobium-iron pre-alloyed ingots according to the atomic percentage of the above-mentioned nanocrystalline soft magnetic alloy, and heat at 1350 ° C for 30 minutes to obtain a superalloy molten steel;

[0125] 2) The high-temperature alloy molten steel is sprayed onto a 30m / s rotating copper roller through a nozzle of a certain shape by a melt quenching method to obtain an amorphous strip; the width of the amorphous strip is 40 mm, and the thickness is 20 μm ;

[0126] 3) The nanocrystalline soft magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com