Construction structure for constructing road on soft soil foundation

A soft soil foundation and road technology, applied in infrastructure engineering, roads, roads, etc., can solve problems such as pedestrian and vehicle threats, concrete road collapse, etc., to improve the bearing capacity and anti-damage ability, reduce collapse, and improve resistance to horizontal displacement. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

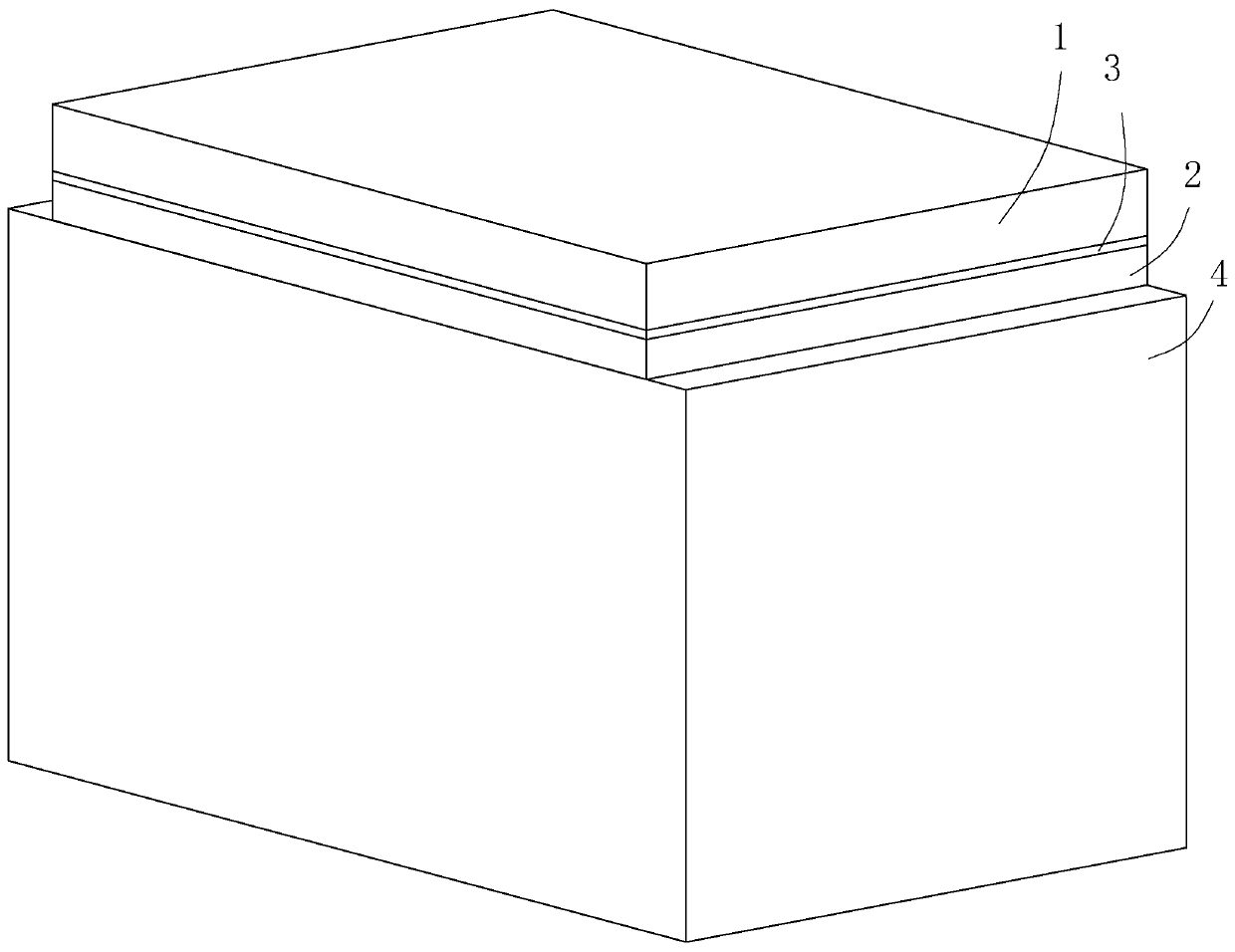

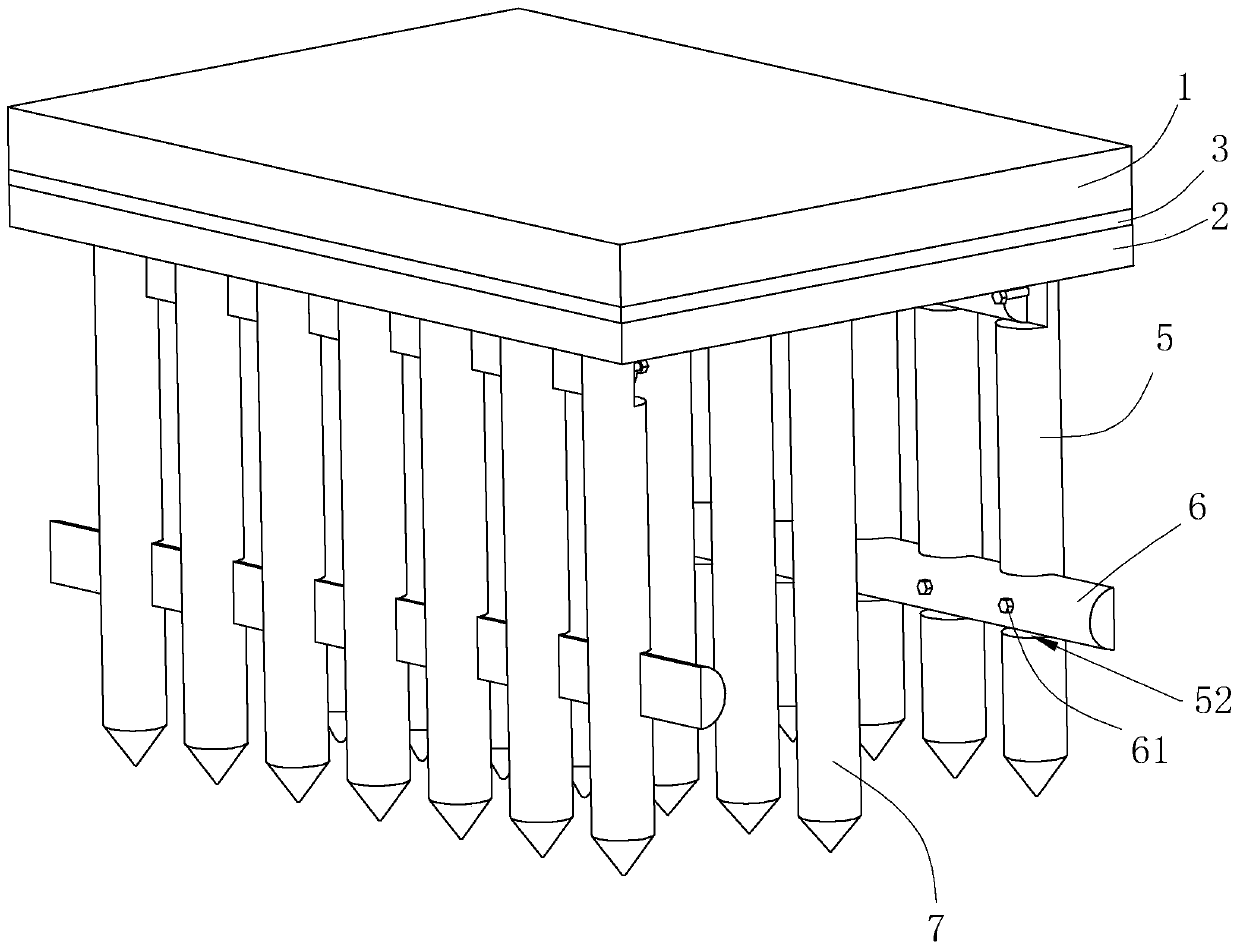

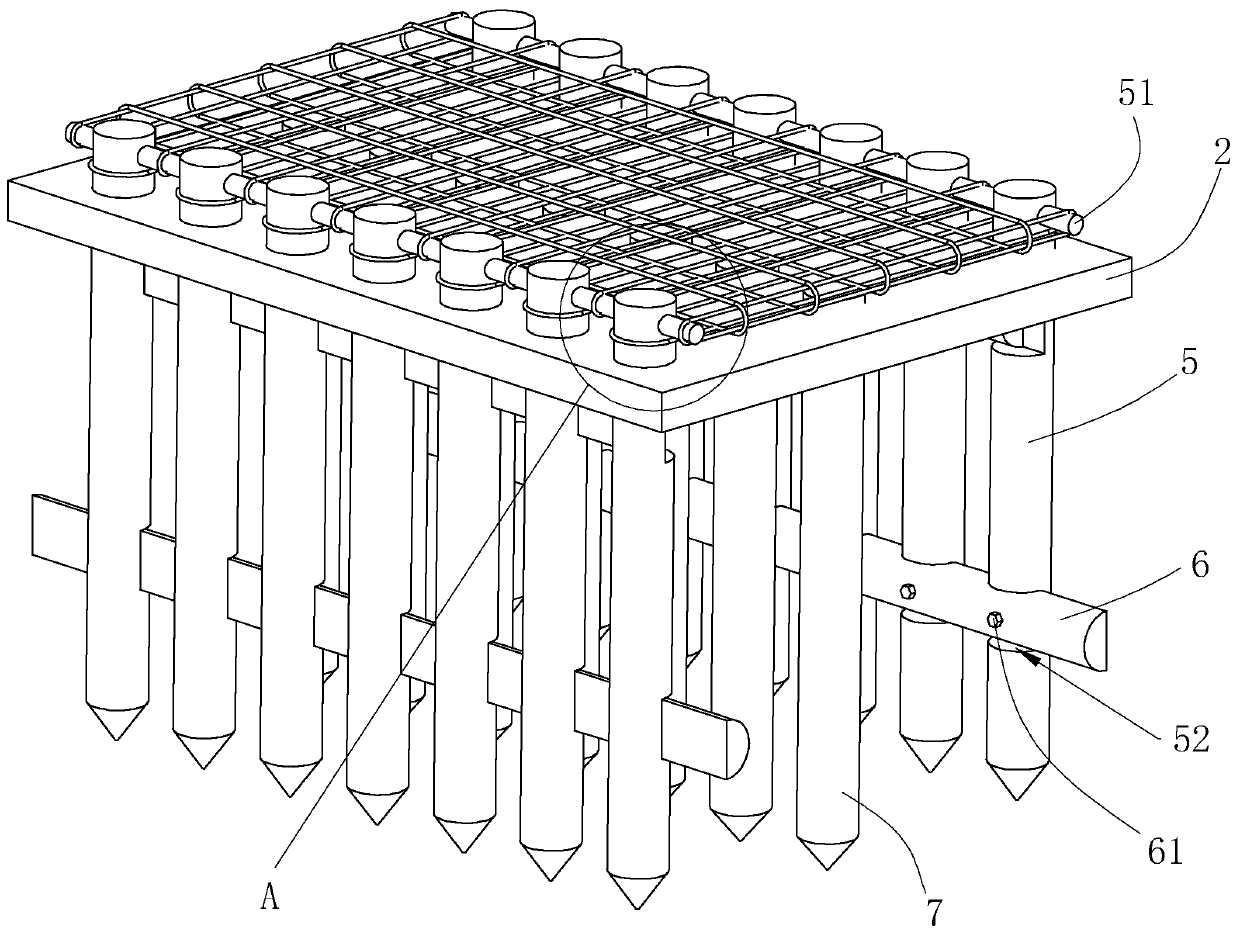

[0034] Such as Figure 1 to Figure 2 As shown, a construction structure for constructing a road on a soft soil foundation disclosed by the present invention includes a gravel layer 2 , a mortar isolation layer 3 and a concrete layer 1 sequentially laid on the soft soil layer 4 . Among them, before laying the crushed stone layer 2, the mortar isolation layer 3 and the concrete layer 1 in turn, drive some vertical pine piles 5 perpendicular to the ground and parallel to each other in the soft soil layer 4, and the vertical pine piles 5 are divided into two arranged side by side. Line up and divide the two sides of the road surface extension direction, wherein a row of anti-bending pine piles 7 is driven between two rows of longitudinal pine piles 5, and the bending-resistant pine piles 7 are parallel to the extension direction of the road surface and parallel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com