Pump pipe quick docking device of automatic control cloth trolley for tunnel lining trolley

A technology for lining trolleys and cloth trolleys, which is applied to tunnel lining, components of pumping devices for elastic fluids, tunnels, etc., can solve problems such as difficulty in stable control of docking conditions, pollution of on-site working environment, labor-hour and labor consumption, etc. , to achieve the effect of convenient disassembly and cleaning, reduced position adjustment requirements, and reduced occupied man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

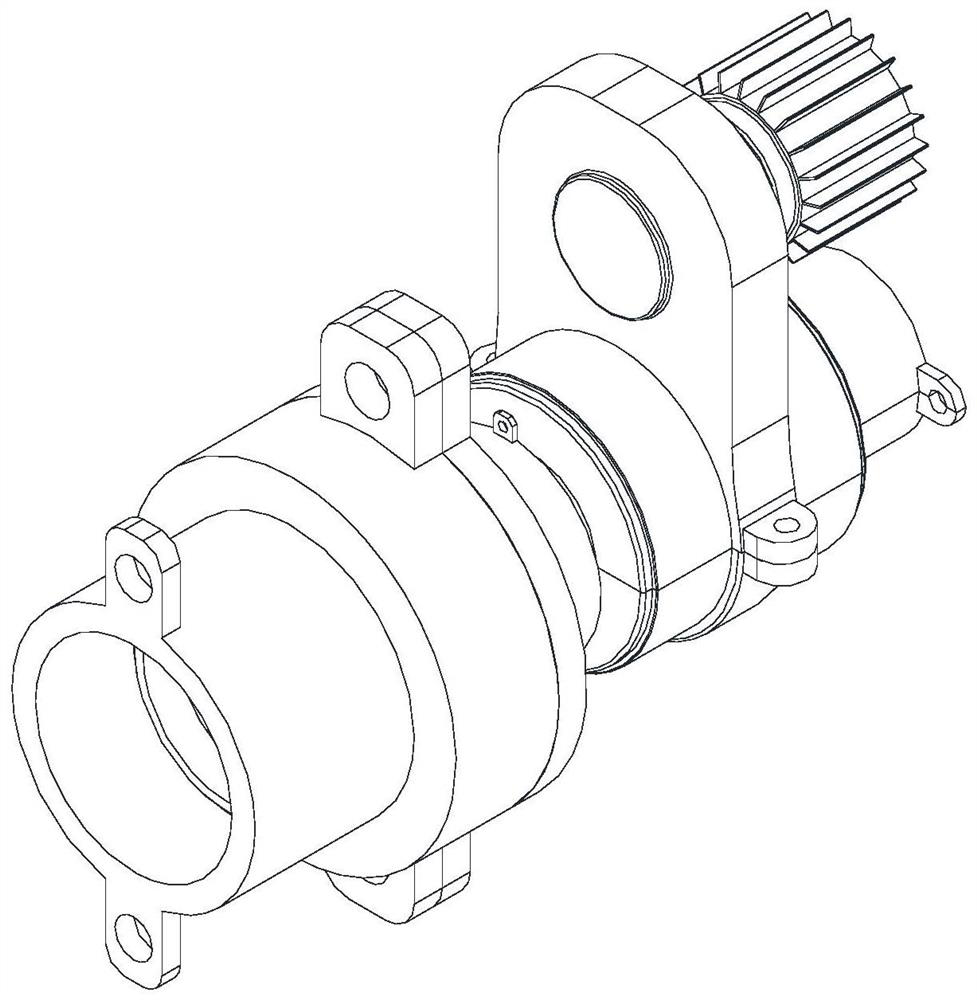

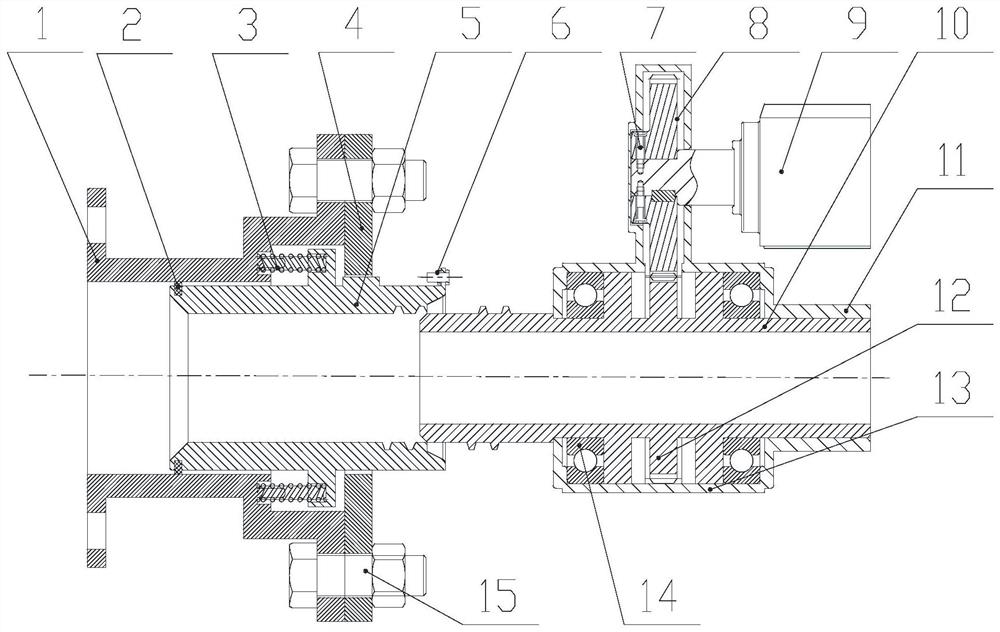

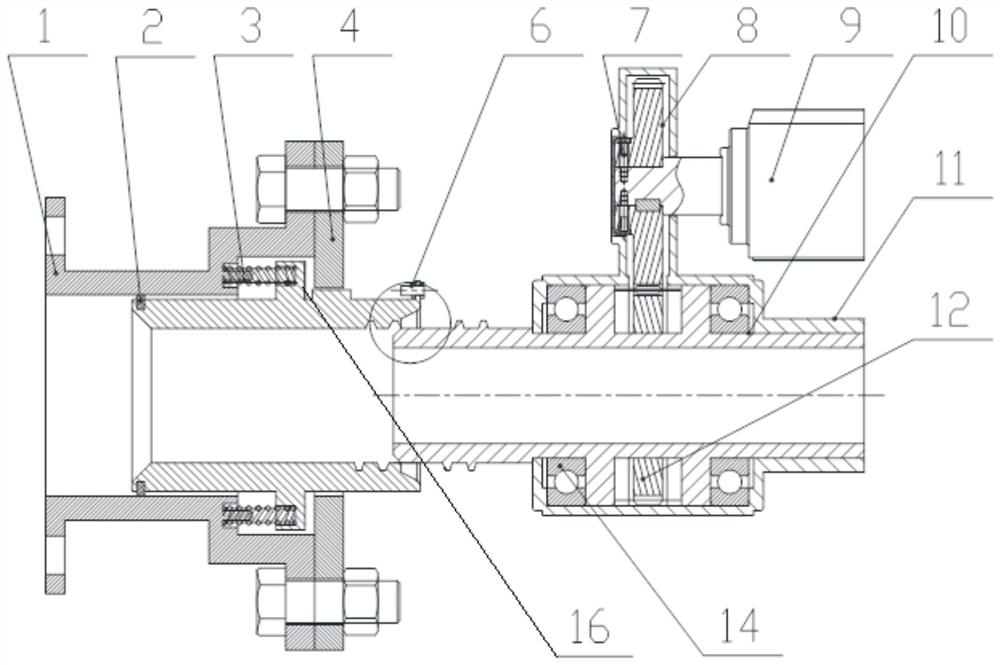

[0033] The following will combine Figure 1-Figure 10 The present invention is described in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0034] A pump pipe rapid docking device for an automatically controlled distributing trolley for a tunnel lining trolley, comprising a docking female pipe connected to the tunnel lining trolley and a docking male pipe connected to the fabric distributing trolley, the docking female pipe includes an internally threaded pump pipe 5 . The internally threaded pump pipe housing 1 arranged outside the internally threaded pump pipe and connected to the tunnel lining trolley also includes an internally threaded pump pipe cover 4 arranged at the entrance of the internally threaded pump pipe; the butt male pipe includes Externally threaded pump tube 10, an externally threaded pump tube housing located outside the externally threaded p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com