Surface-mounted inductor with composite structure and manufacturing method of surface-mounted inductor

A surface-mounted, composite structure technology, applied in the direction of inductance/transformer/magnet manufacturing, inductors, fixed inductors, etc., can solve the problems of exposed magnetic flux leakage of the coil, unbalanced body left and right, and unfixable coil position. Achieve the effects of increasing the area ratio, reducing leakage flux, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

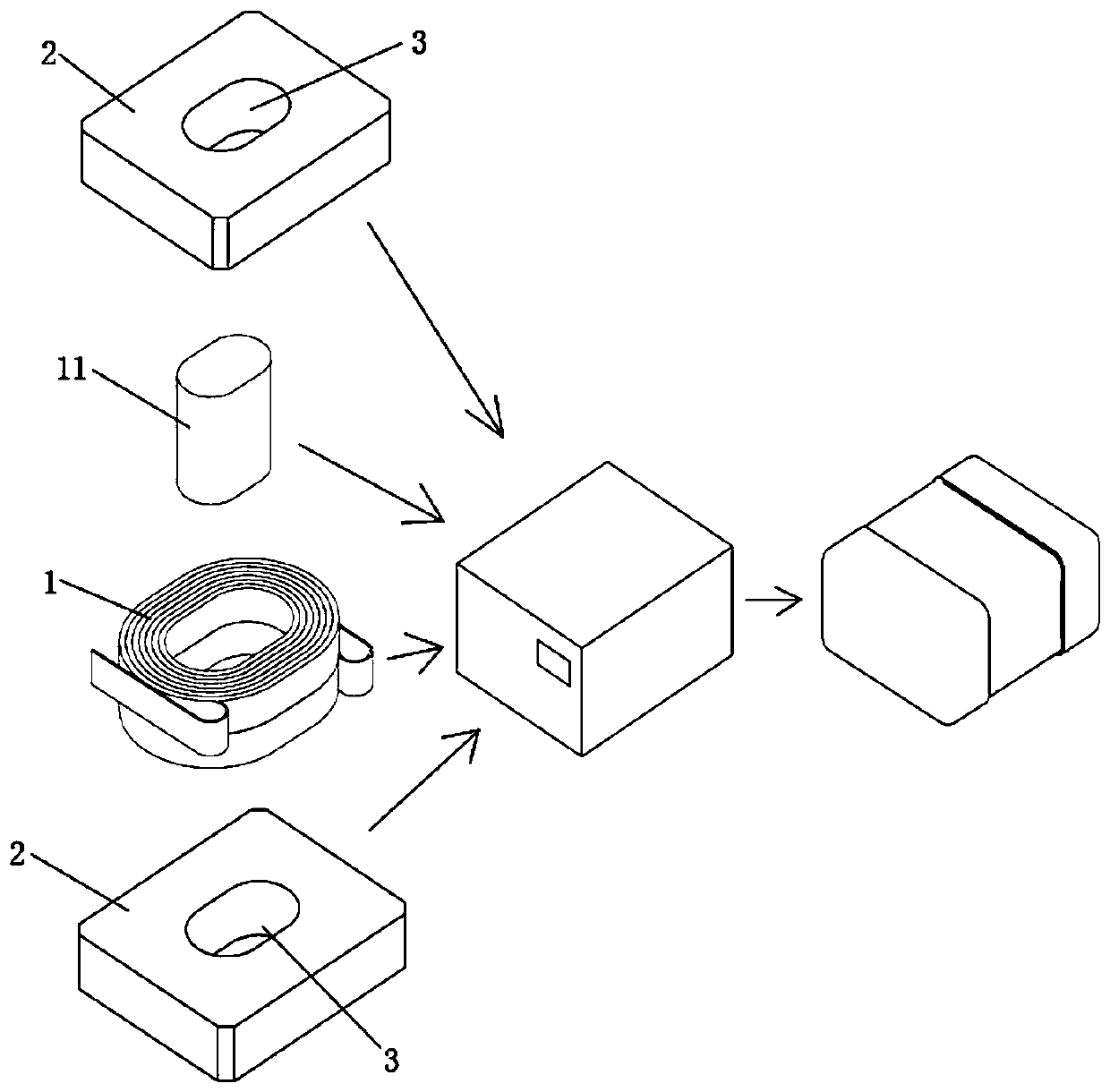

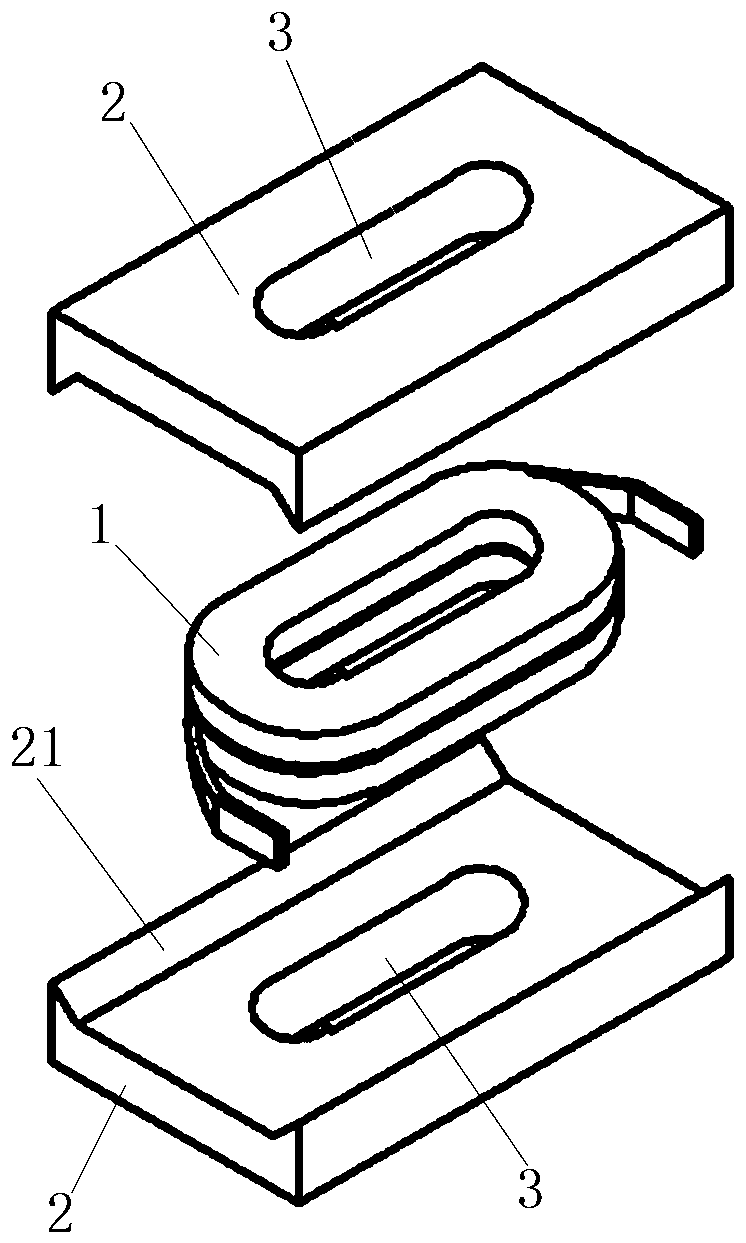

[0021] see figure 1 , figure 2 As shown, it is a structural schematic diagram of a preferred embodiment of the present invention. The present invention is a surface mount inductor with a composite structure, which has a built-in coil 1, a central column 11, and two sets of pressure plate main bodies 2, and the density of the central column 11 It is higher than the density of the main body 2 of the pressing plate, preferably the density of the center column 11 is more than twice the density of the main body 2 of the pressing plate. Through the independently arranged high-density central pillars 11, the magnetic permeability can be improved, and the electrical characteristics can be improved while reducing the overall size of the inductor.

[0022] The specific structure is that the main body 2 of the pressing plate is in the shape of a plate, and the center of the main body 2 of the pressing plate is provided with a track-shaped hole 3, the hole 3 of the main body 2 of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com