Automatic Batch Sample Preparation Method for Button Cells

A button battery, batch production technology, applied in the field of automatic batch sample preparation of button batteries, can solve the problems such as the inability to batch assemble button batteries of different specifications, and achieve the effects of optimized assembly process, controllable capacity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

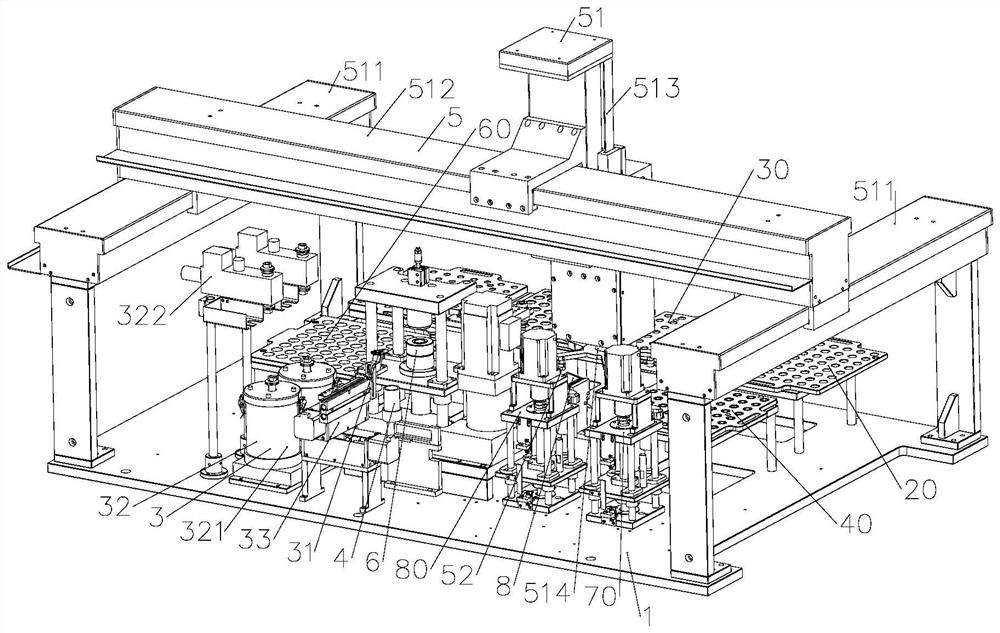

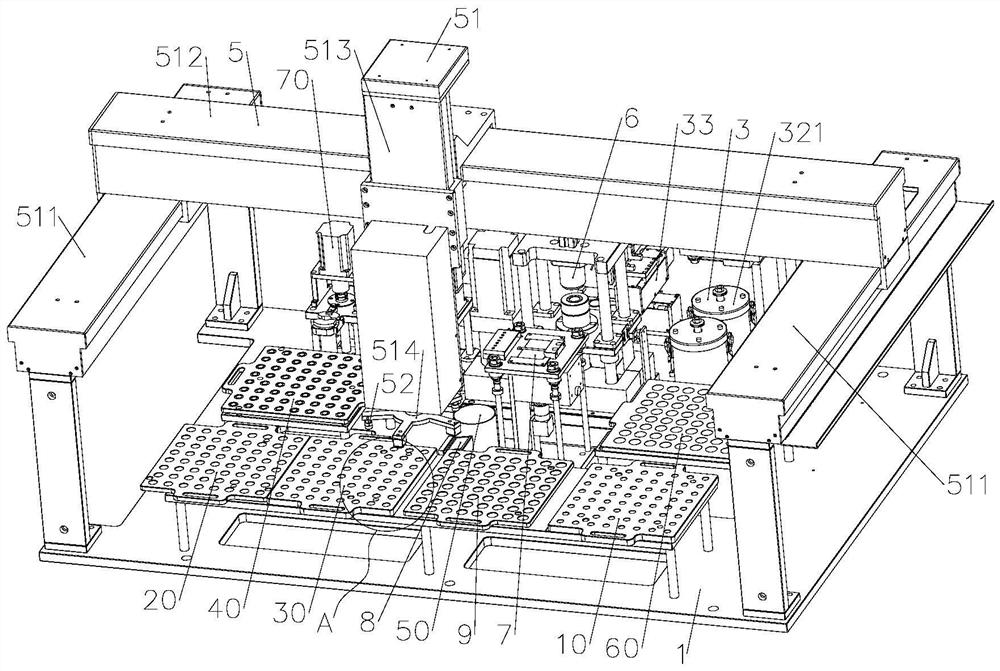

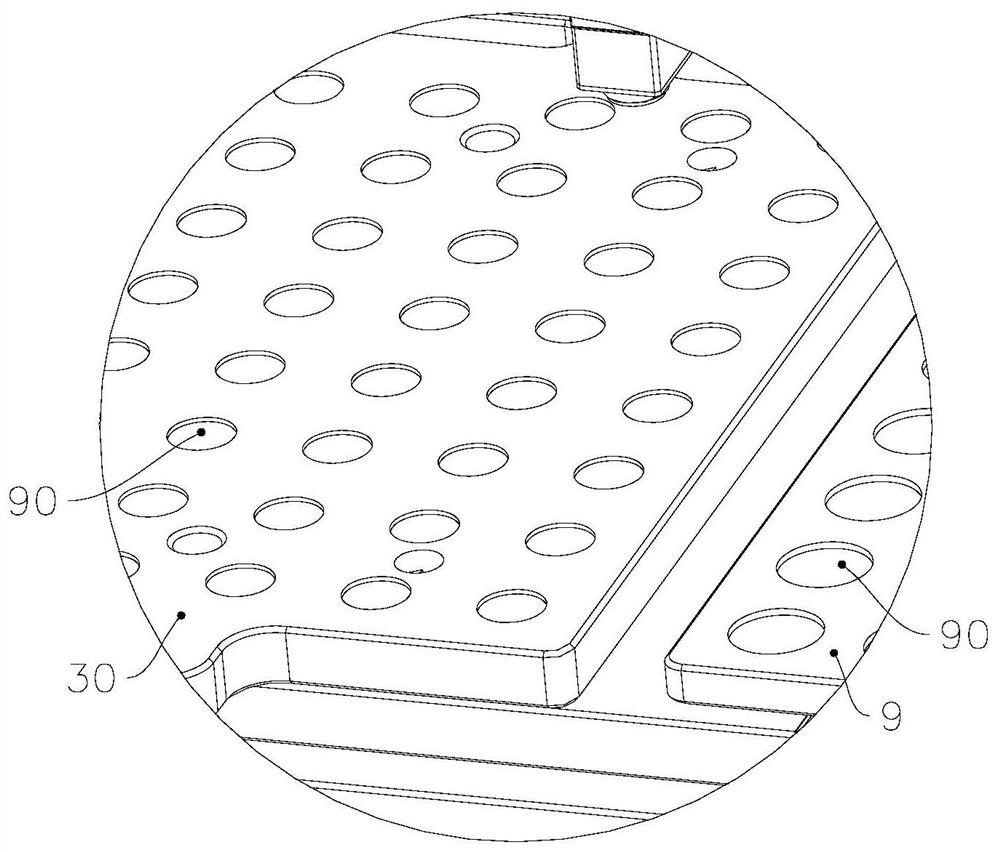

[0057] see Figure 1 to Figure 4 , the sample preparation device used to implement the button battery automatic batch sample preparation method provided by the embodiment of the present invention will now be described. An automatic batch sample preparation device for button cells, including a sealing component 6, a liquid injection component 3, a grasping component 5, a scanning component 8 and a liquid injection scalar component 4 for measuring the electrolyte 28;

[0058] The grabbing component 5 is used to grab components of different specifications from the component tray to the sealing component 6. The component tray is provided with a number of placement slots 90 for placing components of different specifications. The scanning component 8 is used to identify and record The identification information on the component, the liquid injection assembly 3 is used to inject the electrolyte 28 of the volume of the liquid injection scalar assembly 4 into the element located on the...

Embodiment 2

[0080] see figure 1 , figure 2 , Figure 4 and Figure 5 , the button battery automatic batch sample preparation method provided by the present invention is now described. Button battery automatic batch sample preparation method, comprises the following steps:

[0081] S1: Prepare electrolyte 28 and several components of different specifications;

[0082] S2: Adjust the liquid injection volume of the liquid injection component 3, and inject electrolyte 28 into the liquid injection scalar component 4 through the liquid injection component 3 to check the liquid injection volume of the liquid injection component 3 to a preset volume;

[0083] S3: The grabbing component 5 grabs the component to the scanning area of the scanning component 8; the scanning component 8 scans and records the identification information on the component; the grabbing component 5 grabs the component and places it on the sealing component 6; the liquid injection component 3 Inject some predetermine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com