Catalyst structure for syngas production, syngas production device provided with said catalyst structure for syngas production, and production method of catalyst structure for syngas production

A technology for synthesizing gas and manufacturing methods, applied in the direction of catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of reduced catalytic activity and insufficient catalytic activity, and achieve the effect of reducing and suppressing catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~384

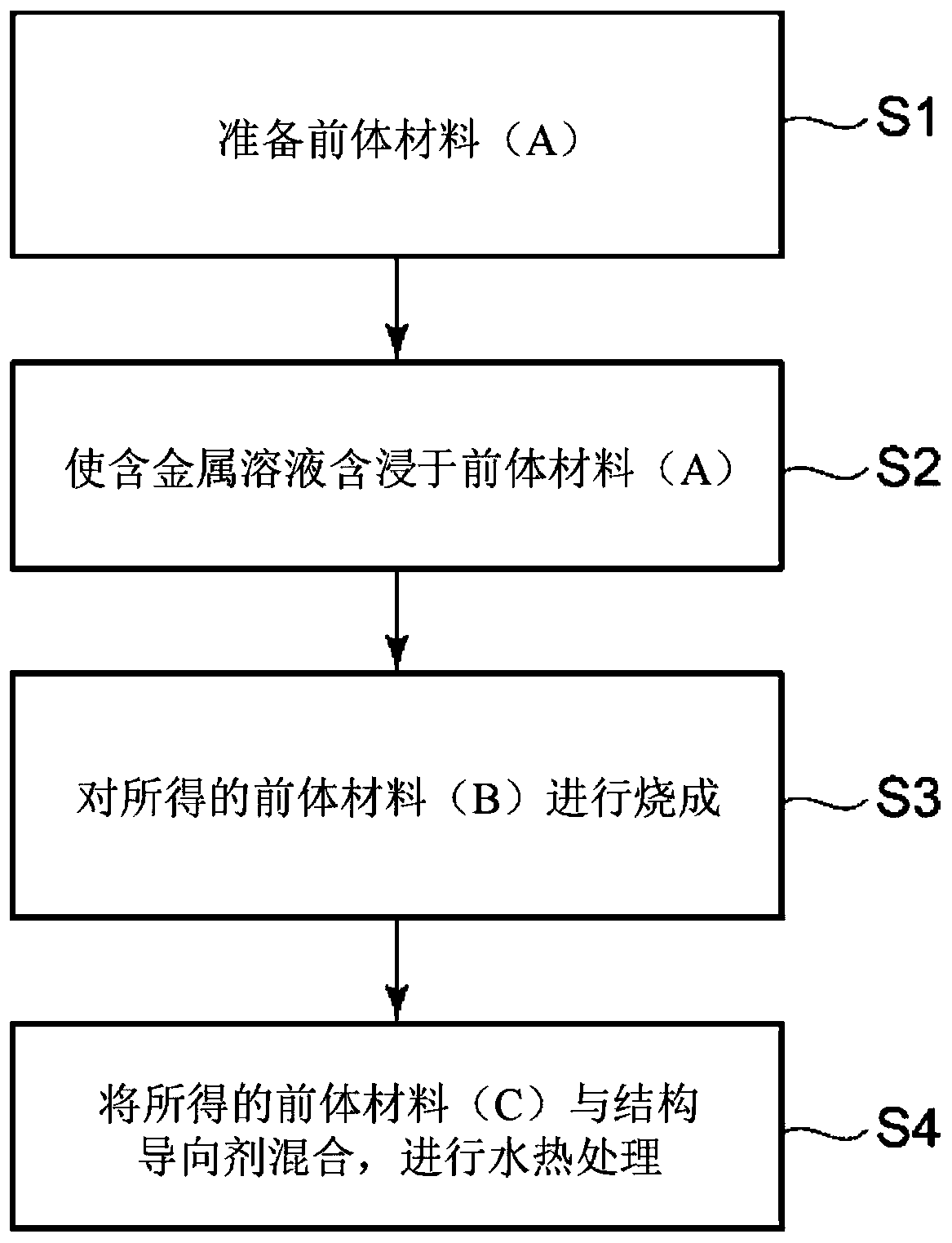

[0109] [Synthesis of precursor material (A)]

[0110] A mixed aqueous solution obtained by mixing a silica agent (tetraethoxysilane (TEOS), manufactured by Wako Pure Chemical Industries, Ltd.) and a surfactant as a templating agent was prepared, and the pH was adjusted appropriately. Hydrothermal treatment was performed at 80 to 350° C. for 100 hours. Then, the generated precipitate was filtered, washed with water and ethanol, and fired at 600° C. in air for 24 hours to obtain precursor materials (A) of the types and pore sizes shown in Tables 1 to 8. In addition, as surfactant, the following thing was used according to the kind of precursor material (A) ("kind of precursor material (A): surfactant").

[0111] ●MCM-41: cetyltrimethylammonium bromide (CTAB) (manufactured by Wako Pure Chemical Industries, Ltd.)

[0112] ●SBA-1: Pluronic P123 (manufactured by BASF Corporation)

[0113] [Production of precursor materials (B) and (C)]

[0114] Next, depending on the metal eleme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com