Microwave horn antennas-based transducer system for CUI inspection without removing insulation

A horn antenna and isolation material technology, which is applied in the direction of using microwave flaw detection, using microwave to test moisture content, analyzing materials, etc., can solve the problems of high cost and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

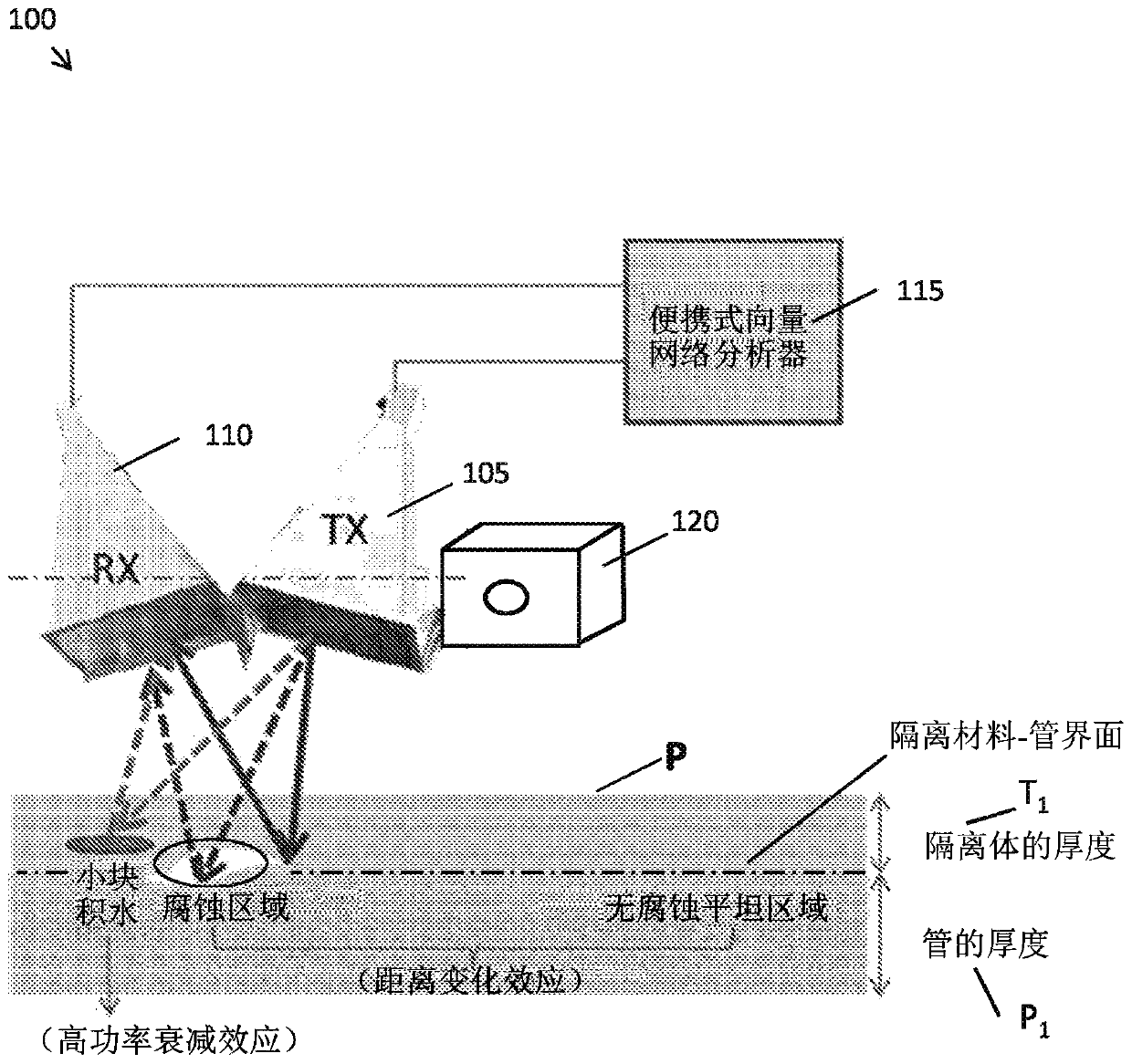

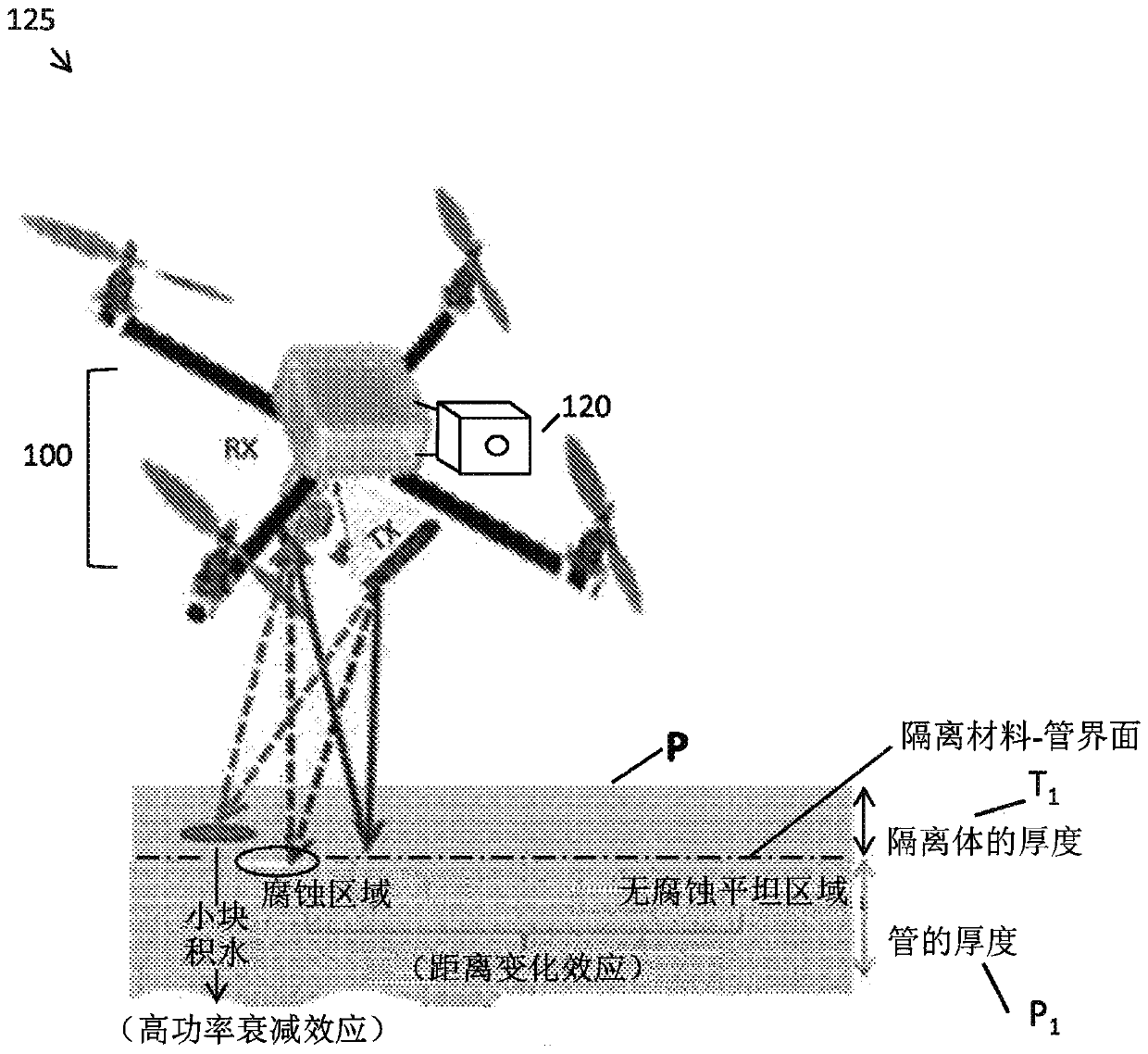

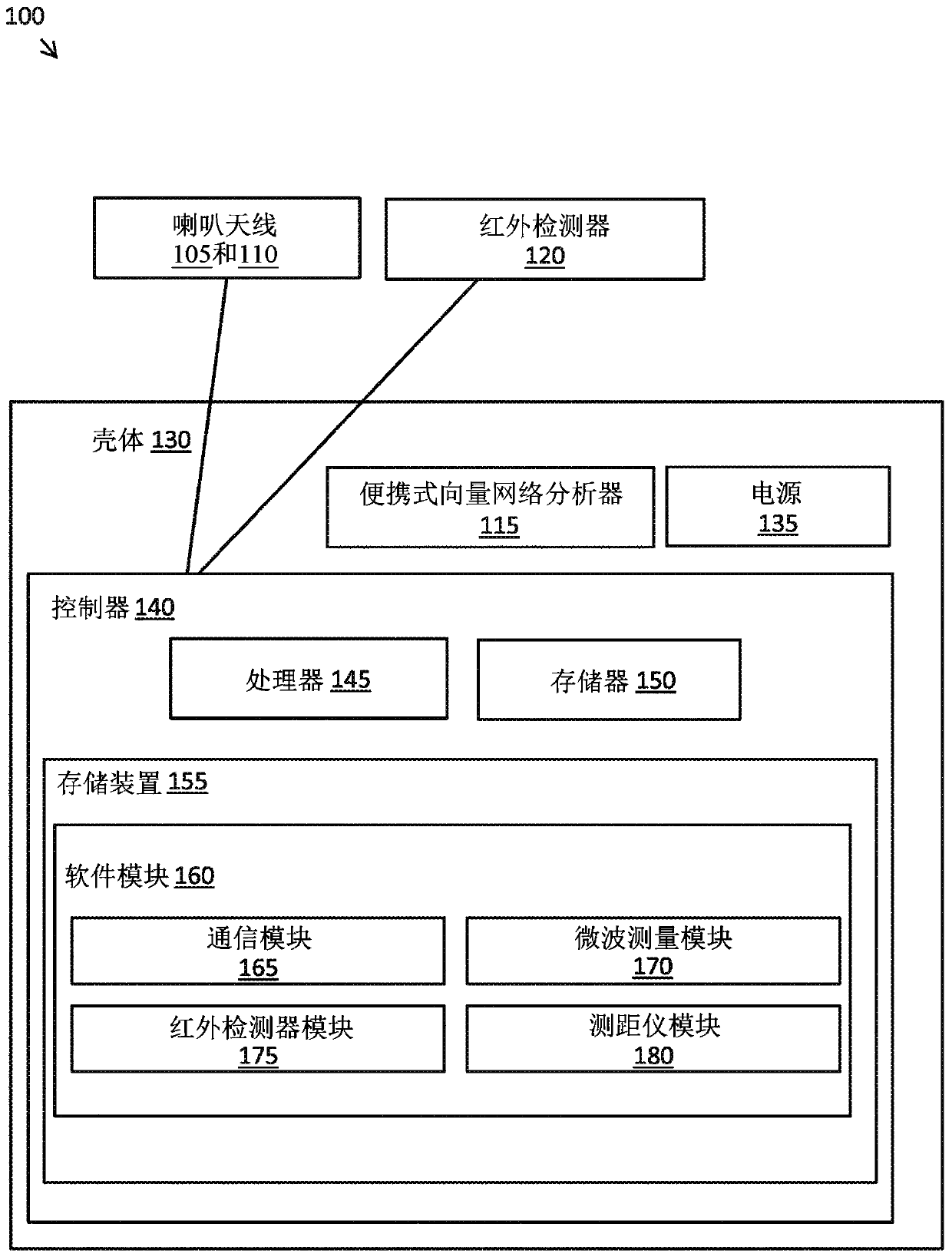

[0024] By way of overview and introduction, the present disclosure details systems and methods for inspecting isolated equipment for corrosion under isolation (CUI) using a microwave horn antenna based transducer system. While it is well understood in the art that CUI can cause substantial damage to isolated equipment, conventional procedures for identifying and repairing areas of equipment damaged by CUI cannot be accurately identified without removing the isolation material for visual inspection Time consuming and costly for damaged equipment areas. Thus, in an effort to increase the efficiency and cost effectiveness of inspections, the systems and methods described herein provide a sequence of operations in which isolated equipment is assessed for possible CUI damage without having to remove the isolation material in the equipment.

[0025] More specifically, in accordance with at least one embodiment of the present application, a microwave horn antenna based transducer sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com