Device used of high-pressure production of high-solid low-viscosity acrylic acid in laboratories, and production process

A technology for laboratory and preparation equipment, which is applied in the field of high-solid and low-viscosity acrylic acid preparation equipment for high-pressure production in the laboratory, and can solve the problems of large solvent usage, long process route, and failure to realize PLC automatic control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

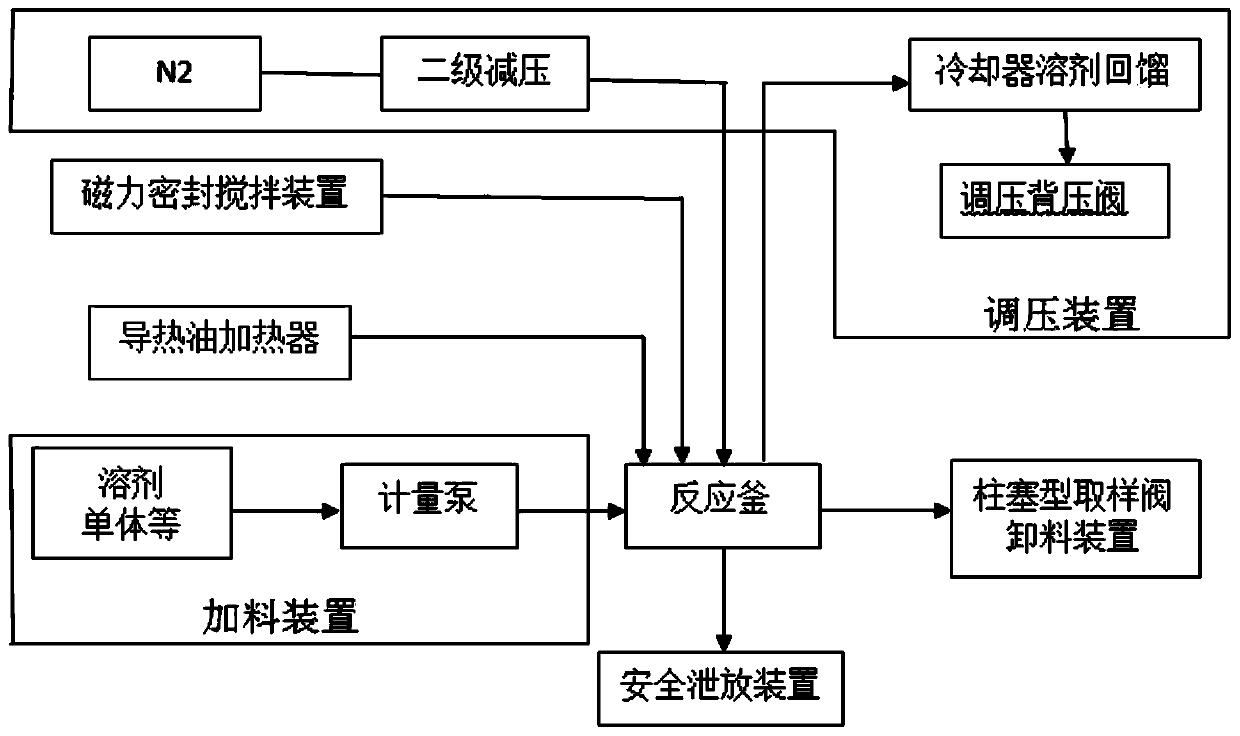

[0027] Such as figure 1 As shown, a laboratory high-pressure production of high-solid low-viscosity acrylic acid preparation equipment, including a reaction kettle for holding the reaction solvent, a feeding device for adding raw materials, a stirring device for reaction stirring, and a reaction liquid The back distillation device for feeding back and the discharge device for outputting the reaction product; the feeding device, the stirring device, the back distillation device and the discharge device are respectively installed on the reaction kettle.

[0028] In order to facilitate the heating or cooling of the mixture in the reactor, the preparation device of the present invention also includes a heating and cooling device for heating and cooling the reaction liquid, and the heating and cooling device is installed on the outer wall of the reactor.

[0029] In order to facilitate the monitoring of the pressure in the reactor and prevent danger caused by excessive pressure, th...

Embodiment 2

[0032] A production process for a high-solid and low-viscosity acrylic acid preparation device for high-pressure production in a laboratory, comprising the following steps:

[0033] (1) add initiator, monomer raw material and butyl acetate solvent in reactor by feeding device;

[0034] (2) The mixture in the reactor is heated by the heating and cooling device; meanwhile, the mixture is stirred and reacted by the stirring device;

[0035] (3) carry out back distillation condensation to the hot steam of the butyl acetate solvent that reaction in reactor produces by back distillation device;

[0036] (4) The pressure in the reaction kettle is detected by the pressure sensing device, and the detection data is transmitted to the control device. When the pressure in the reaction kettle reaches the preset upper limit, the control device controls the pressure regulating device to open and release Pressure, when the pressure in the reactor reaches the preset lower limit, the control d...

Embodiment 3

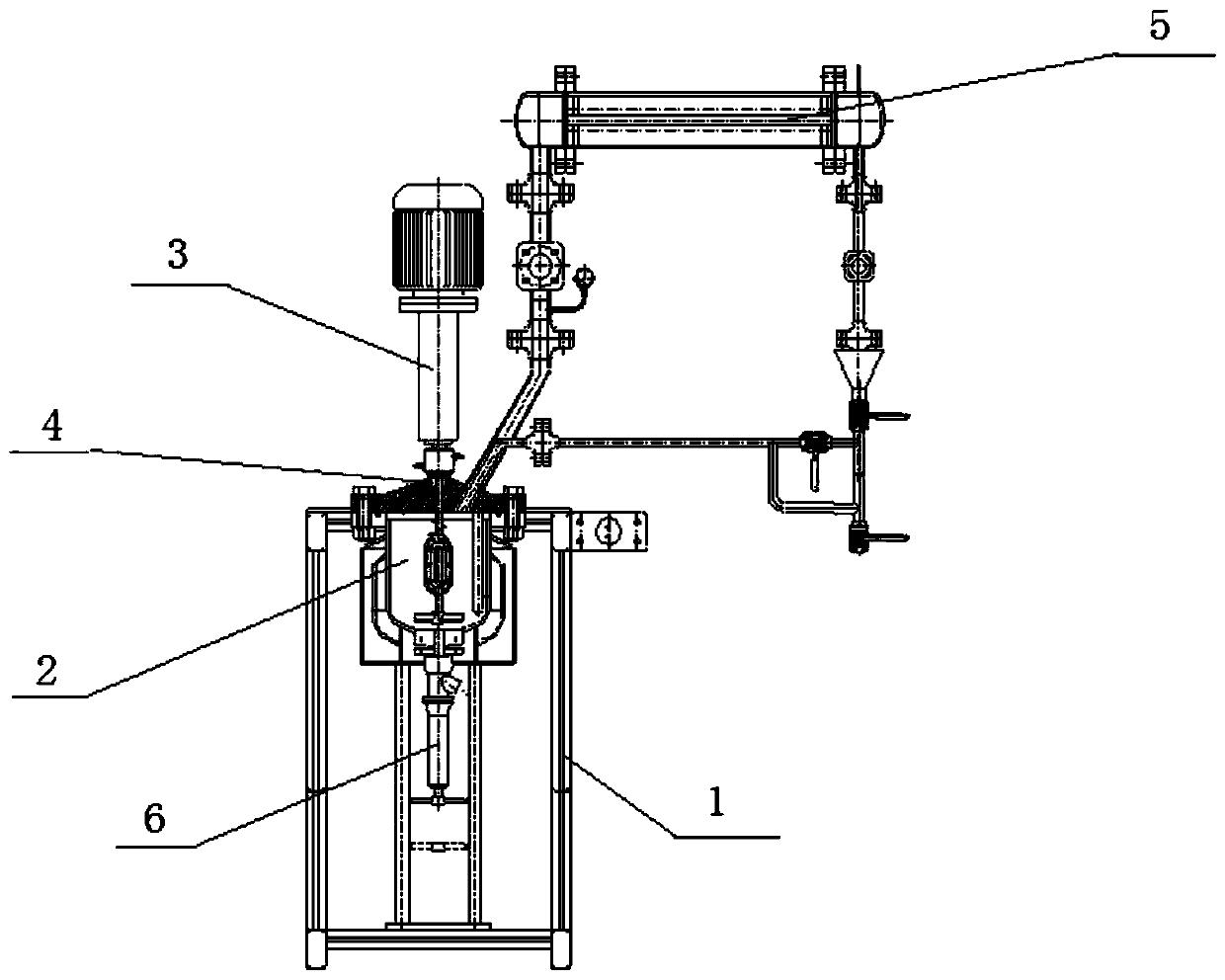

[0040] A laboratory high-pressure production of high-solid and low-viscosity acrylic acid preparation equipment, including a frame 1, a high-pressure reactor 2 is fixedly installed on the frame 1, a magnetic coupling stirrer 3 is sealed and installed on the high-pressure reactor 2, and the magnetic coupling The stirring shaft of the agitator 3 extends into the autoclave 2, and a gooseneck (not shown) is also installed on the autoclave 2, one end of the gooseneck is connected with the autoclave 2, and the other end of the gooseneck is One end is connected with the tubular condenser 5, and the return end of the tubular condenser 5 is communicated with the high-pressure reactor 2, and the high-pressure reactor 2 is also provided with a dosing metering pump (not shown) for adding raw materials, A plunger type sampling valve 6 is installed at the bottom of the autoclave 2 to discharge the product after the reaction. A pressure sensor for detecting the reaction pressure, a back press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com