A method for synthesizing gem-grade colorless diamonds by seed crystal method

A technology of synthetic gemstones and seed crystal method, which is applied in the direction of using atmospheric pressure to change substances chemically, chemical instruments and methods, and the process of applying ultra-high pressure, etc., which can solve the problem of unsatisfactory chromaticity and clarity of colorless diamonds , internal defects, impurities, many inclusions, long synthesis process time, etc., to improve product quality, nitrogen removal efficiency, growth promotion and growth inhibition coordination, and good synthesis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for synthesizing gem-grade colorless diamonds by seed crystal method, comprising the steps of:

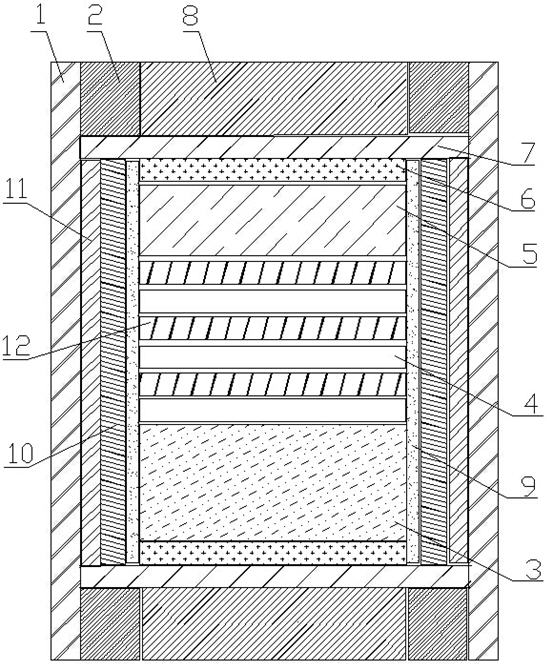

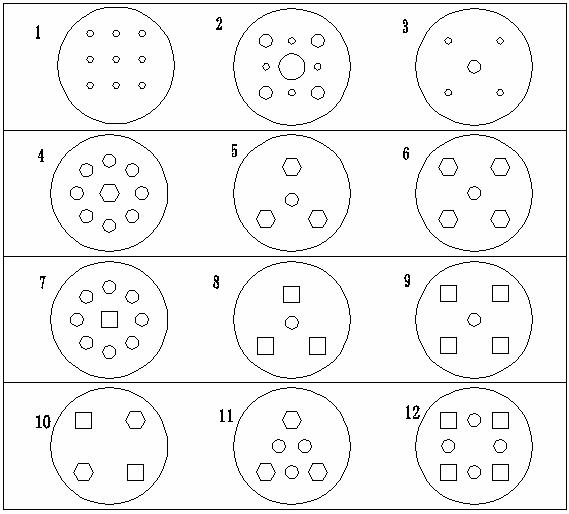

[0026] (1) FeMnCo is used as a catalyst sheet, graphite with a purity of 99% is used as a carbon source, and Cu foil is used as a nitrogen removal agent. The thickness of the Cu foil is 0.03 mm. The end faces are flush according to figure 1 Assemble the blocks;

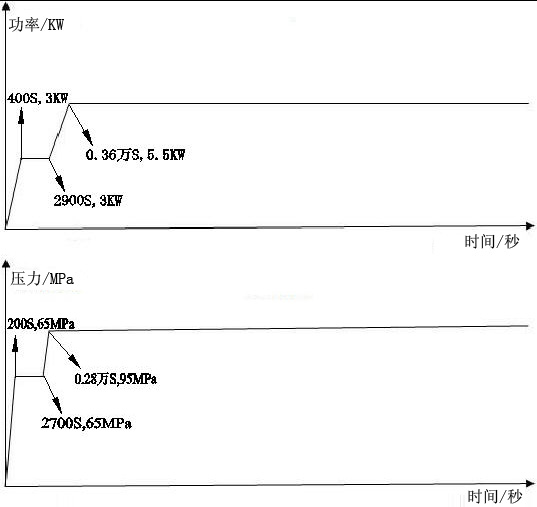

[0027] (2) Then start high temperature and high pressure synthesis, the pressure rises to 65MPa at a constant speed in 200s and then maintains for 2500s, and then rises to 95MPa at a constant speed for 100s; the heating power rises to 3.0KW at a constant speed for 400s, then keeps for 2500s, and then increases to 700 Rise to 5.5 KW at a constant speed in seconds; heat preservation and pressure at 95MPa pressure and 5.5KW heating power until the 10,000th second. The heating power and pressure are gradually reduced and then gradually increased to 5.5KW and 95MPa. The total synthesis time is 900,000 Seconds...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com