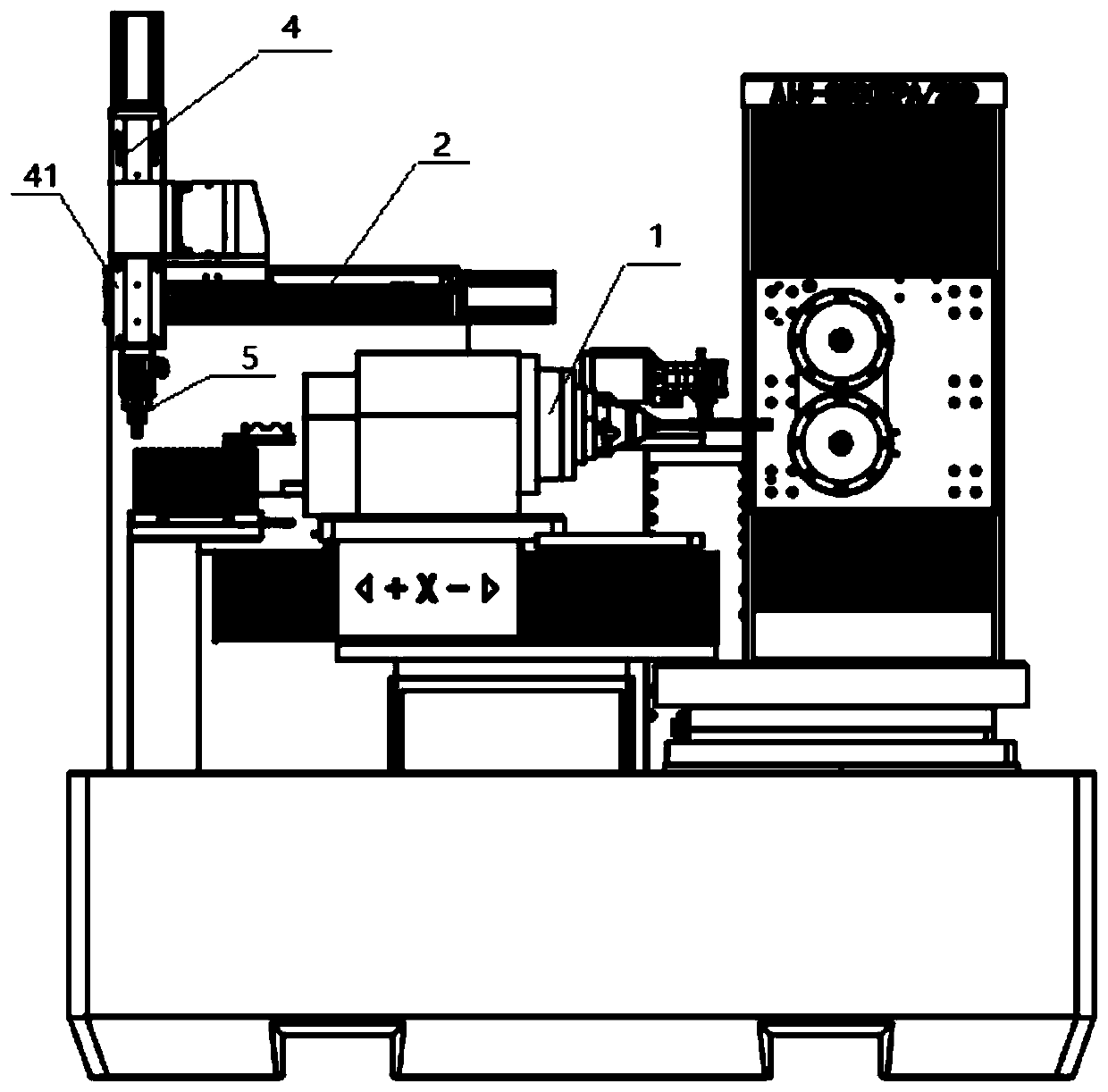

Automatic feeding and discharging mechanism for five-axis grinding machine

An automatic loading and unloading and grinding machine technology, which is applied to the parts of grinding machine tools, grinding feed movement, grinding/polishing equipment, etc., can solve the problems of large safety hazards, increased costs, unfavorable manual operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

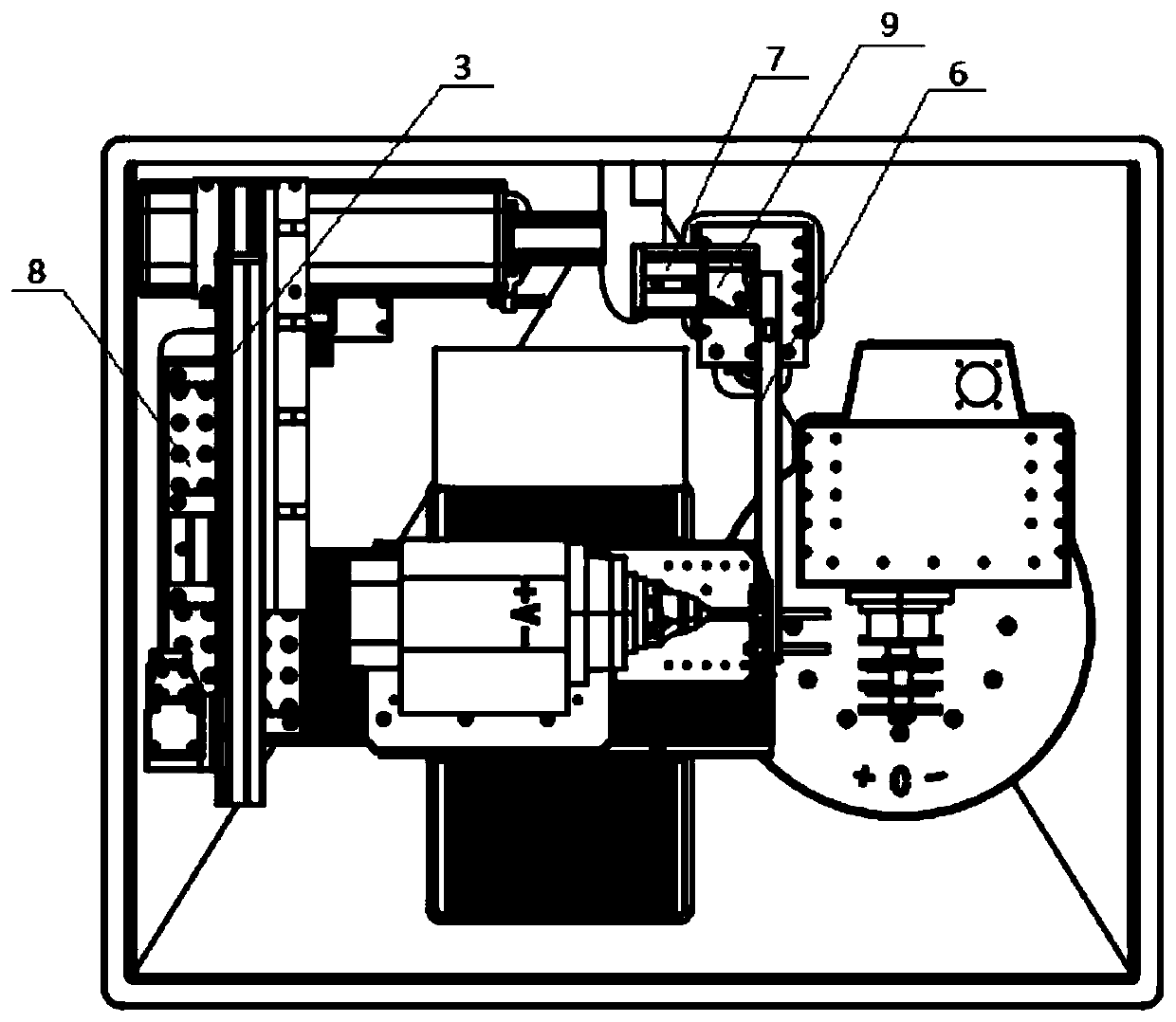

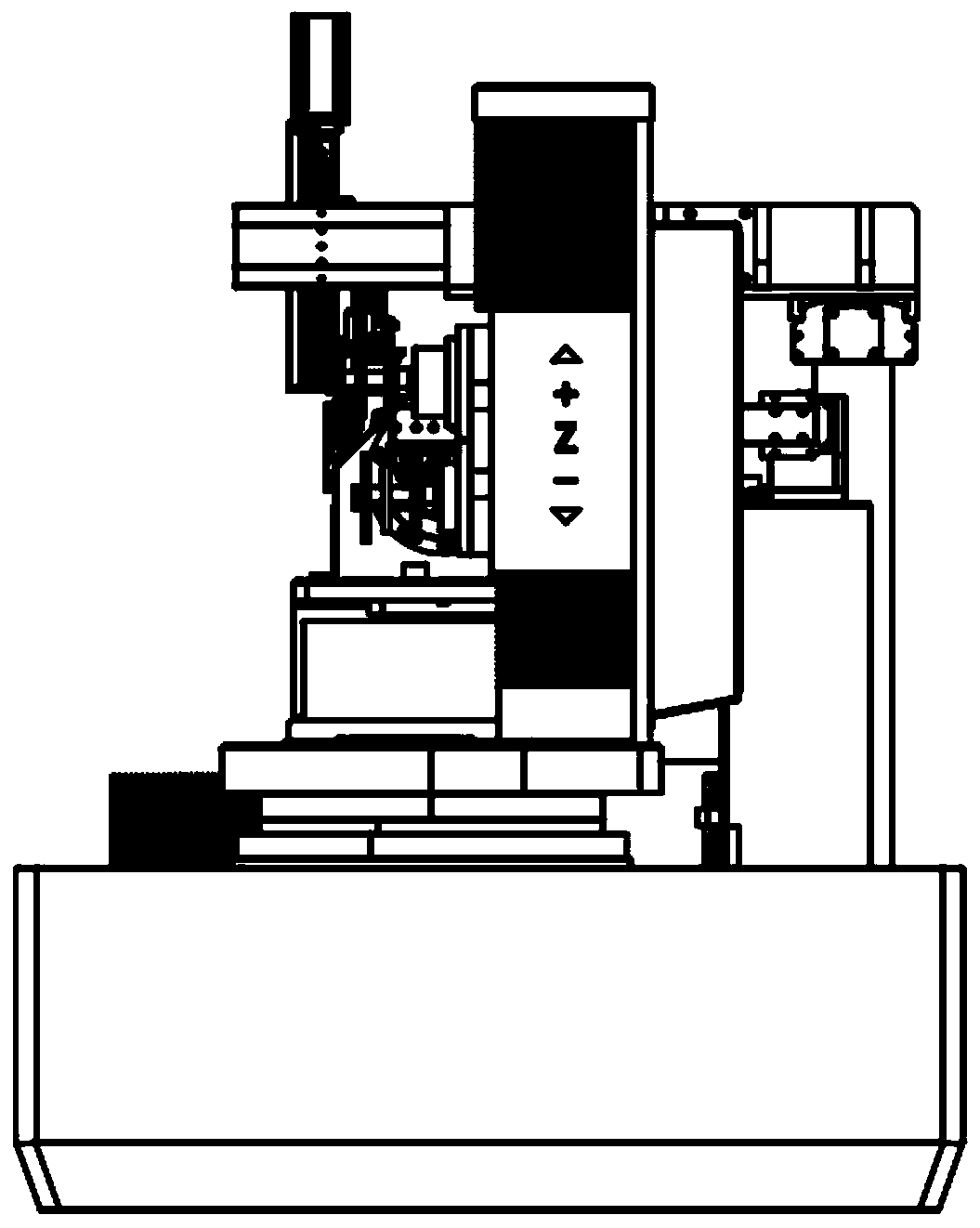

[0026] The five-axis CNC grinding machine disclosed in this case integrates the five-axis grinding machine with the automatic loading and unloading device of this case, and places the loading and unloading device in a limited space, which not only saves the space occupied by the equipment, but also makes maintenance more convenient.

[0027] The first track of the automatic loading and unloading device disclosed in this case is fixedly connected to the base of the grinding machine (bolt connection is enough), and then the signal control end of the automatic loading and unloading device is connected with the control system of the CNC grinding machine, so that it can be controlled through the operation interface of the CNC grinding machine Automatic loading and unloading, and receiving the torque feedback of the servo motor in the additional axis, it is convenient for the on-site operators to control the equipment and improve work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com