Municipal wastewater treatment method

A technology of municipal sewage and treatment method, applied in the field of municipal sewage treatment, can solve the problem of difficult recycling of municipal sewage, and achieve the effect of high sewage treatment quality, reduction of bacterial and virus content, and improvement of capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

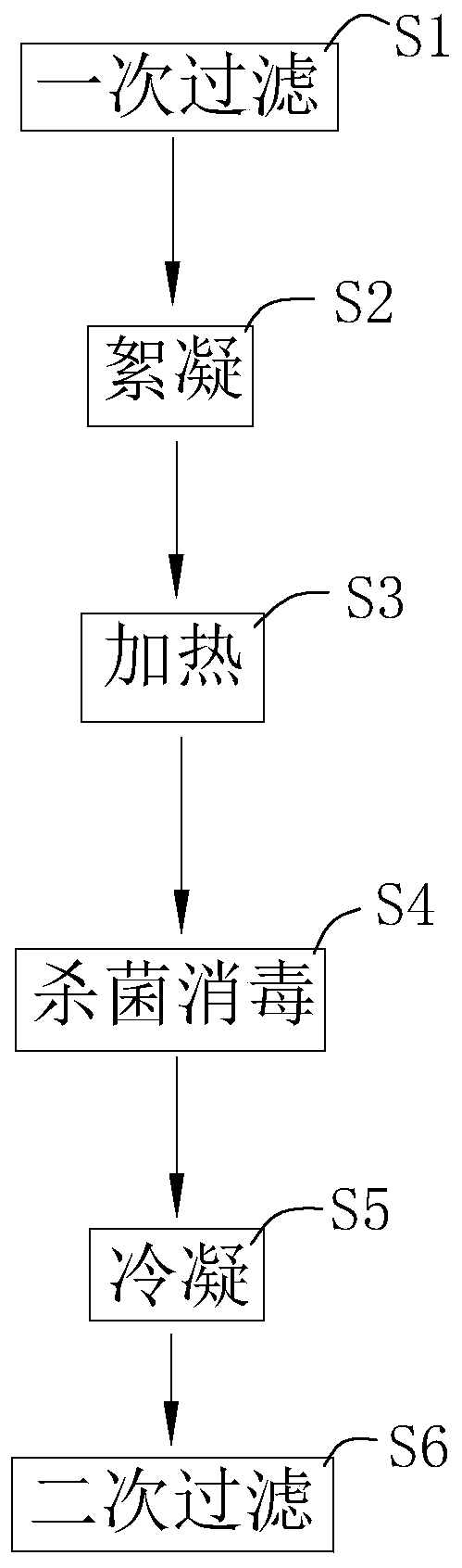

Method used

Image

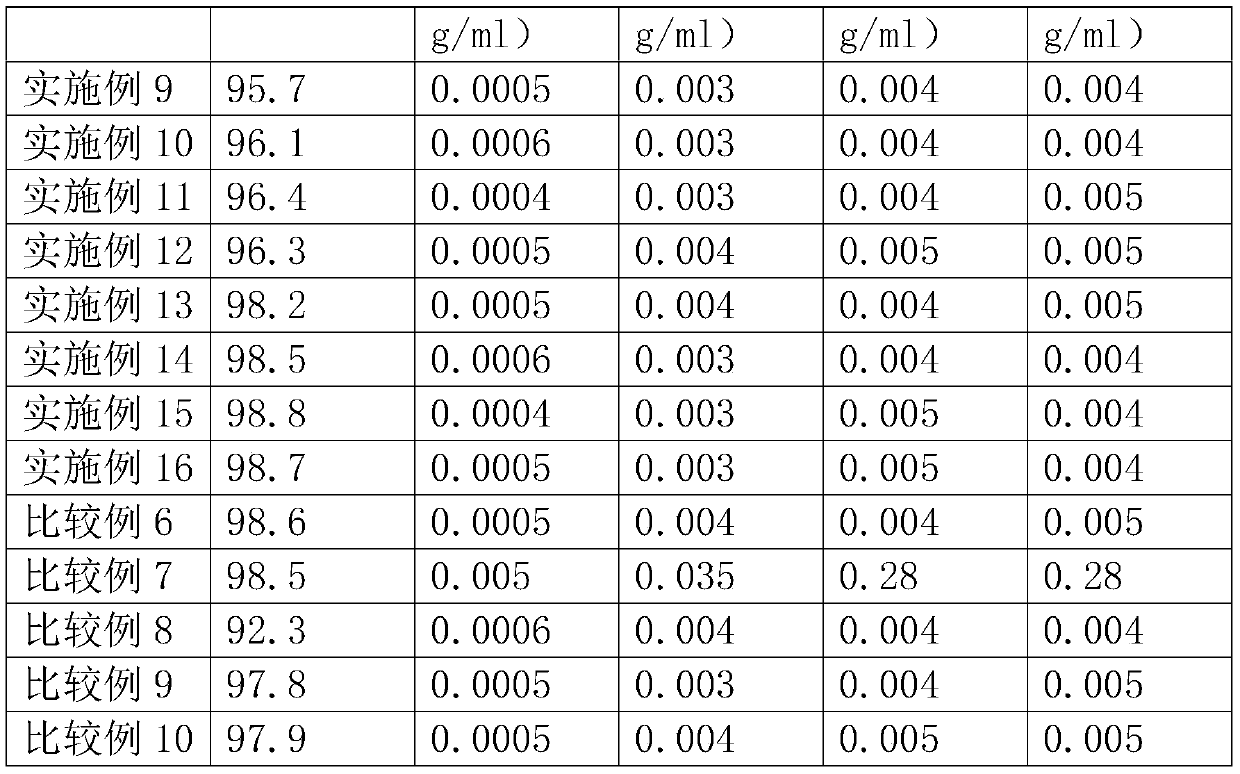

Examples

Embodiment 1

[0069] A kind of flocculant, the preparation method of flocculant is as follows:

[0070] a. Add polyacrylamide, methylcellulose, casein, and 2-aminoisonicotinic acid to the grinding equipment and grind them into powders with a particle size of 100nm±10nm;

[0071] b. Add 100kg of polyacrylamide powder, 20kg of methyl cellulose powder, 5kg of casein powder, and 0.01kg of 2-aminoisonicotinic acid powder into the stirred tank, close the stirred tank, feed in nitrogen, exhaust air, and rotate at 150r / min , stirred for 10 minutes to form a premix;

[0072] c. Put the premix into a granulator and press to form a granular flocculant, and then pack it for dry storage.

Embodiment 2

[0074] A kind of flocculant, the preparation method of flocculant is as follows:

[0075] a. Add polyacrylamide, methylcellulose, casein, and 2-aminoisonicotinic acid to the grinding equipment and grind them into powders with a particle size of 100nm±10nm;

[0076] b. Add 100kg of polyacrylamide powder, 22.5kg of methyl cellulose powder, 7.5kg of casein powder, and 0.015kg of 2-aminoisonicotinic acid powder into the stirred tank, close the stirred tank, feed in nitrogen, discharge air, and rotate at a speed of 150r / min, stirring for 10min to form a premix;

[0077] c. Put the premix into a granulator and press to form a granular flocculant, and then pack it for dry storage.

Embodiment 3

[0079] A kind of flocculant, the preparation method of flocculant is as follows:

[0080] a. Add polyacrylamide, methylcellulose, casein, and 2-aminoisonicotinic acid to the grinding equipment and grind them into powders with a particle size of 100nm±10nm;

[0081] b. Add 100kg of polyacrylamide powder, 25kg of methyl cellulose powder, 10kg of casein powder, and 0.02kg of 2-aminoisonicotinic acid powder into the stirred tank, close the stirred tank, feed in nitrogen, and exhaust air at a speed of 150r / min , stirred for 10 minutes to form a premix;

[0082] c. Put the premix into a granulator and press to form a granular flocculant, and then pack it for dry storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com