Large-diameter drilling and core taking device and method

A drilling core and large-diameter technology, which is applied in the direction of extracting undisturbed core devices, drill bits, drill pipes, etc., can solve the problem that the coring device cannot meet the needs of large-diameter coring, and achieve the identification of coal rock rock burst tendency demand, improve the core quality, and ease the drilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

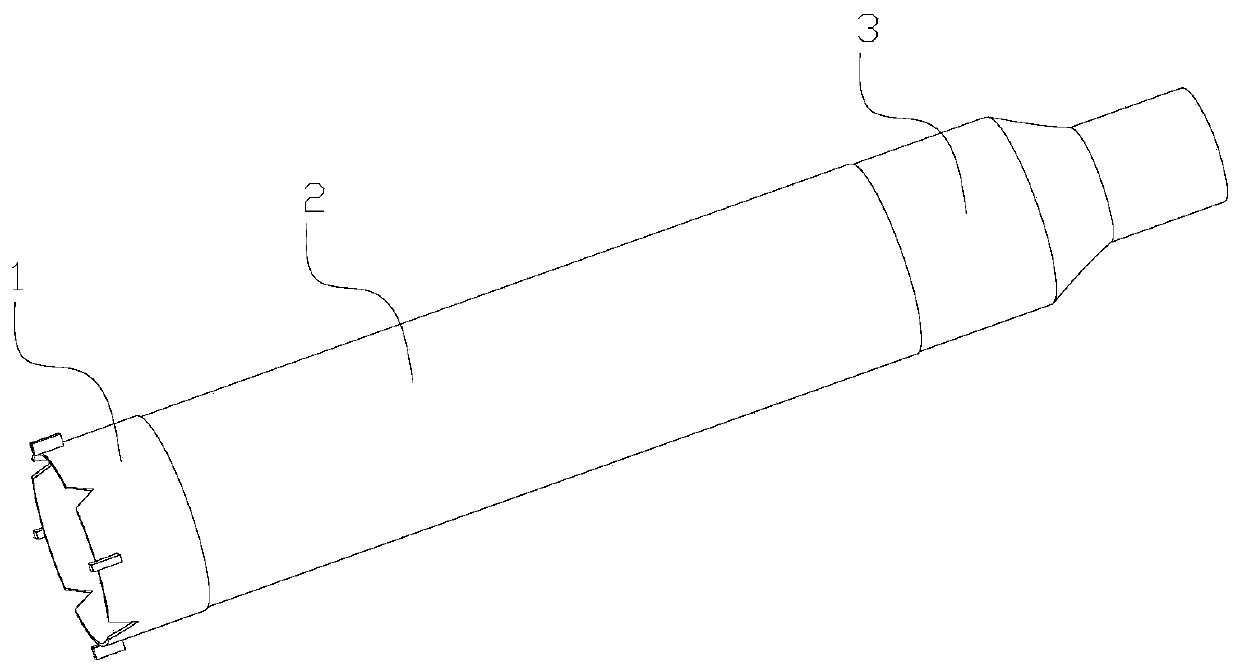

[0044] Such as Figure 1-Figure 3 As shown, the large-diameter drilling coring device includes a coring bit 1, a core tube 2, and a screw head 3 connected in sequence, and the coring bit 1, the core tube 2 and the screw head 3 are connected to form a front end that is empty. core space.

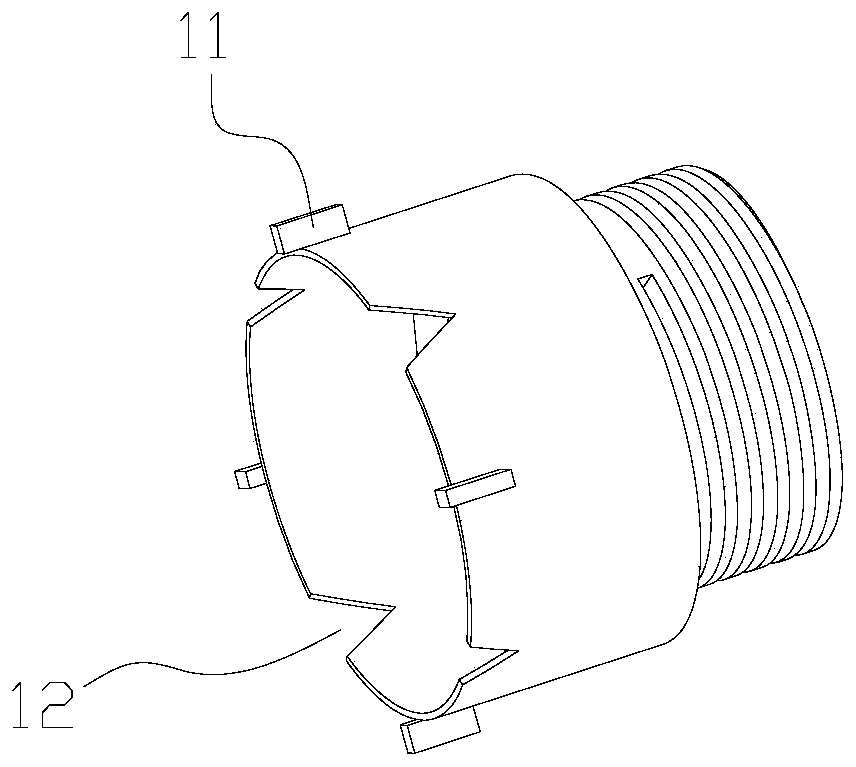

[0045] Such as figure 2 As shown, the core drill bit 1 has a diameter of Φ133mm, an external diameter of the drill bit of Φ130mm, and a wall thickness of 8mm. The front end is welded with a plurality of blades 11 along the circumference. In this embodiment, the blades are diamond composite sheets. mm, and four "V-shaped" water outlets 12 are processed at the front end of the drill bit. The diamond composite sheet is made of cemented carbide material, with a tensile strength of 750MPa-1500MPa, while the normal tensile strength of rocks in the rock formations taken is 20MPa-200MPa, and the maximum tensile strength is 350MPa, which can meet the needs.

[0046] Such as image 3 As shown, the...

Embodiment 2

[0065] The difference between this embodiment and the first embodiment is that the length of the core pipe 2 is 500 mm.

[0066] In Example 1, the length of the core tube 2 is 1m. Because the diameter difference between the core tube 2 and the drilled hole is small (about 3mm), coal and rock powder deposits in the drilled hole for a long time are easy to slagging and the slag is not smooth, resulting in buried drilling and coring. Failed, therefore, this embodiment processes a 500mm long core tube, reduces the length of the difference between the core tube 2 and the borehole diameter and the length of a single coring, to ensure the integrity of slag removal and coring.

Embodiment 3

[0068] The difference between the present embodiment three and the embodiment one is: the method of taking out the rock core from the rock core tube 2 is different in step S05;

[0069] The method of removing the core from the core tube 2 in Embodiment 1 is easy to cause destructive force on the core; in this embodiment, after the drilling rig is leveled, the pressure water is turned on to flush the core out of the core tube 2 to avoid damage from knocking core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com