Primary and secondary bottom spray type laser welding diamond drill bits and manufacturing method thereof

A diamond drill bit and laser welding technology, which is used in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of inability to guarantee the quality of the drill bit and restrict the development of the diamond bit, so as to improve the safety performance, reduce thermal fatigue damage, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

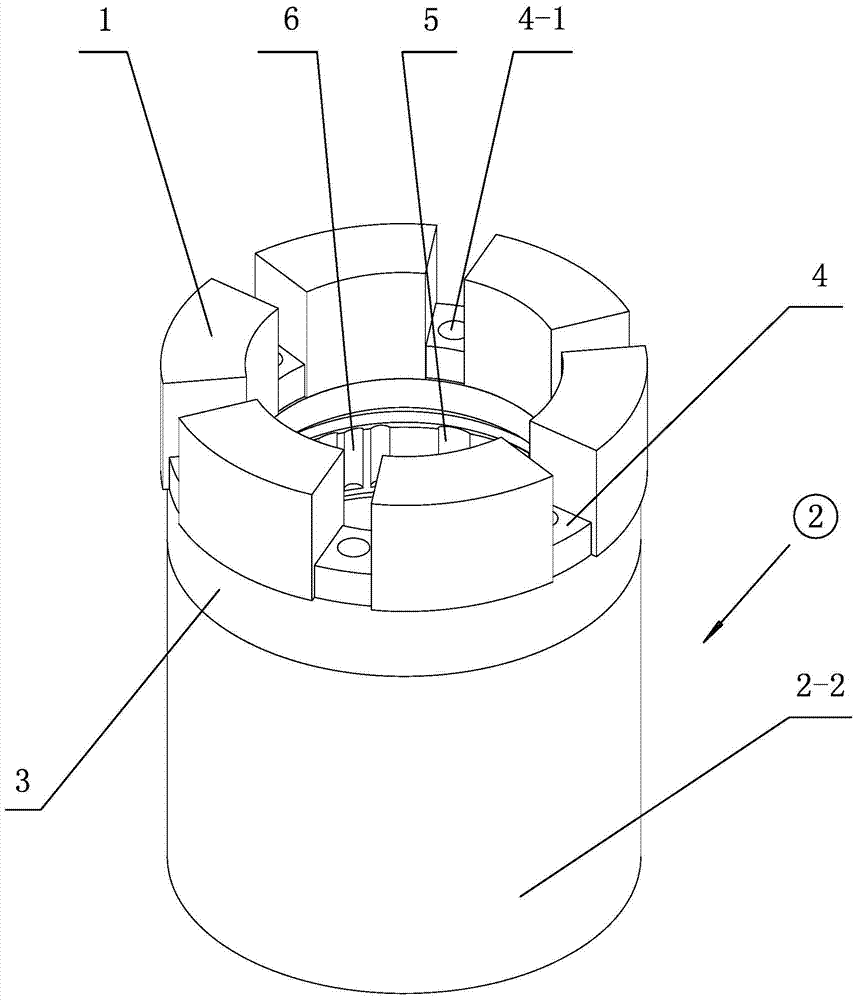

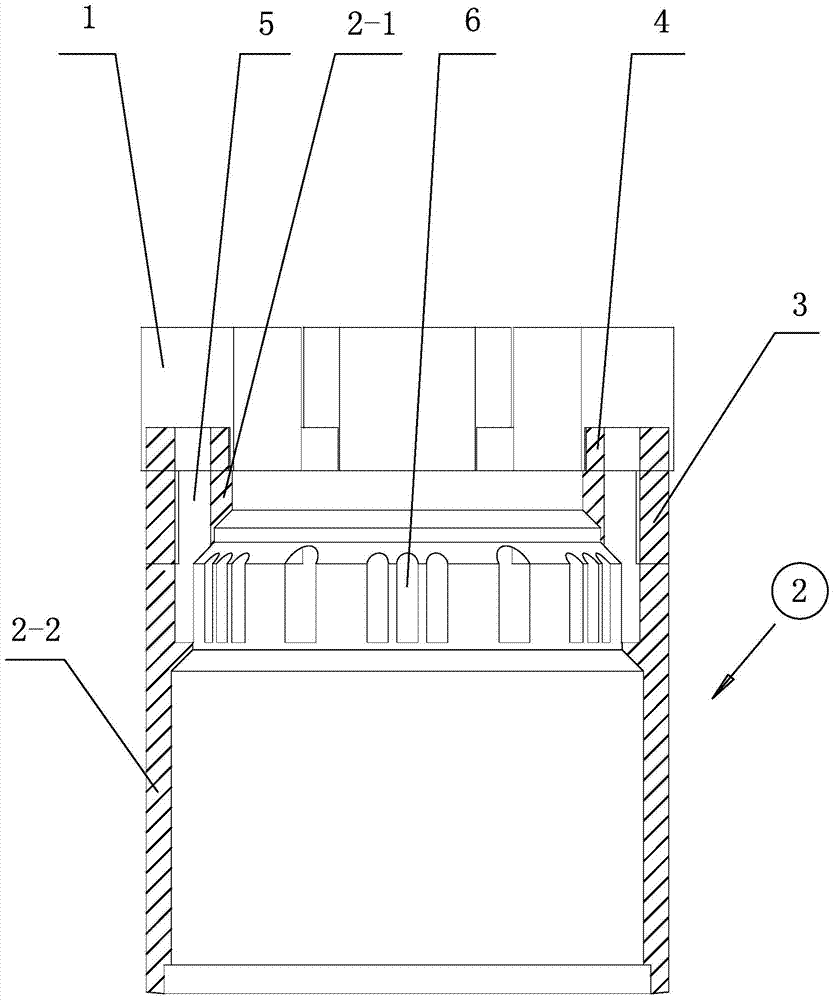

[0034] The main and auxiliary bottom spray type laser welding diamond drill bits of the present invention include six drill matrixes 1 , a steel pipe matrix 2 , a reinforcing ring 3 and six water blocking blocks 4 .

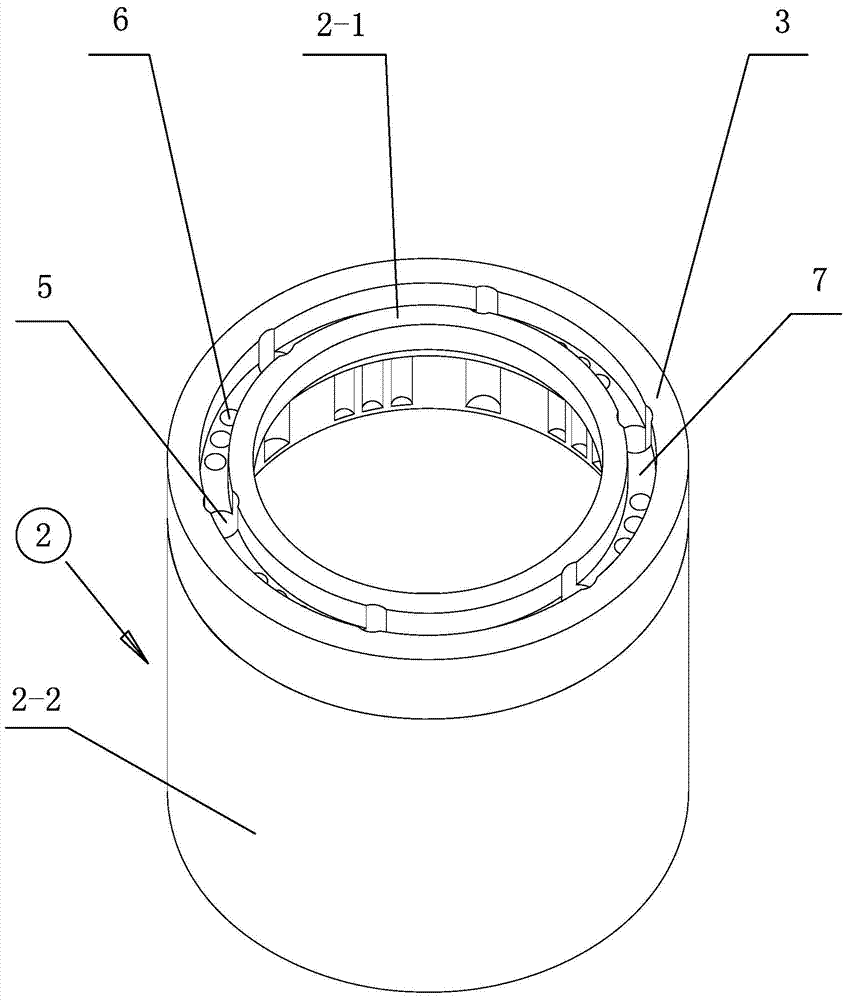

[0035] The nozzle 2-1 at the upper end of the steel pipe matrix 2 (with a wall thickness of 3 mm to 10 mm) is smaller than the pipe body 2-2 and a step is formed between the nozzle 2-1 and the pipe body 2-2 (the axial height is 3 mm to 8 mm) , the outer diameter of the reinforcing ring 3 is equal to the diameter of the pipe body 2-2, and the height is flush with the nozzle 2-1, and the reinforcing ring 3 is coaxially fitted with the nozzle 2-1 on the step and is fitted with the pipe body 2- 2. Laser welding is used to form a semi-closed water flow ring cavity 7 between the reinforcing ring 3, the nozzle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com