Online soft measurement method for as-fired coal amount based on burner video signals

A technology of the amount of coal into the furnace and video signals, which is applied in the field of combustion flame image processing, can solve the problems that the model performance is not mentioned, and the amount of pulverized coal into the boiler combustion system cannot be realized, so as to achieve the effect of optimal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

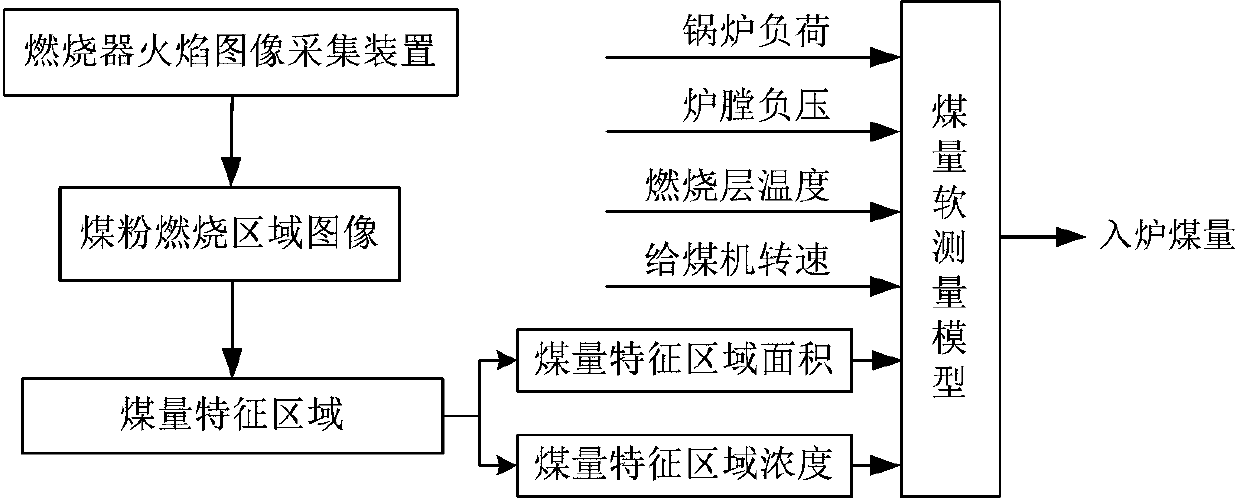

[0030] The combustion of pulverized coal in the boiler directly affects the temperature of the boiler furnace. Through the present invention, the amount of pulverized coal in the furnace can be measured online. The main steps are as follows: figure 1 shown.

[0031] Combustion image is collected by burner combustion image sensor, what the embodiment of the present invention uses is the 8-bit RGB color combustion image that CCD camera obtains, as figure 2 shown. The RGB image has three channels, which correspond to the red, green, and blue components of the color image respectively. Firstly, the burning image is processed in gray scale, which is expressed by the following formula. The processed image is as follows: image 3 shown

[0032]

[0033] In the formula, , , ——the value corresponding to each channel at the pixel point; ——...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com