Doubling image detector

A technology of magnifying mirror and support rod, which is applied in the field of magnifying image detectors, can solve the problems of unrecognizable by human eyes, large projector area, and inaccurate judgment, so as to improve detection accuracy, save working space, The effect of simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

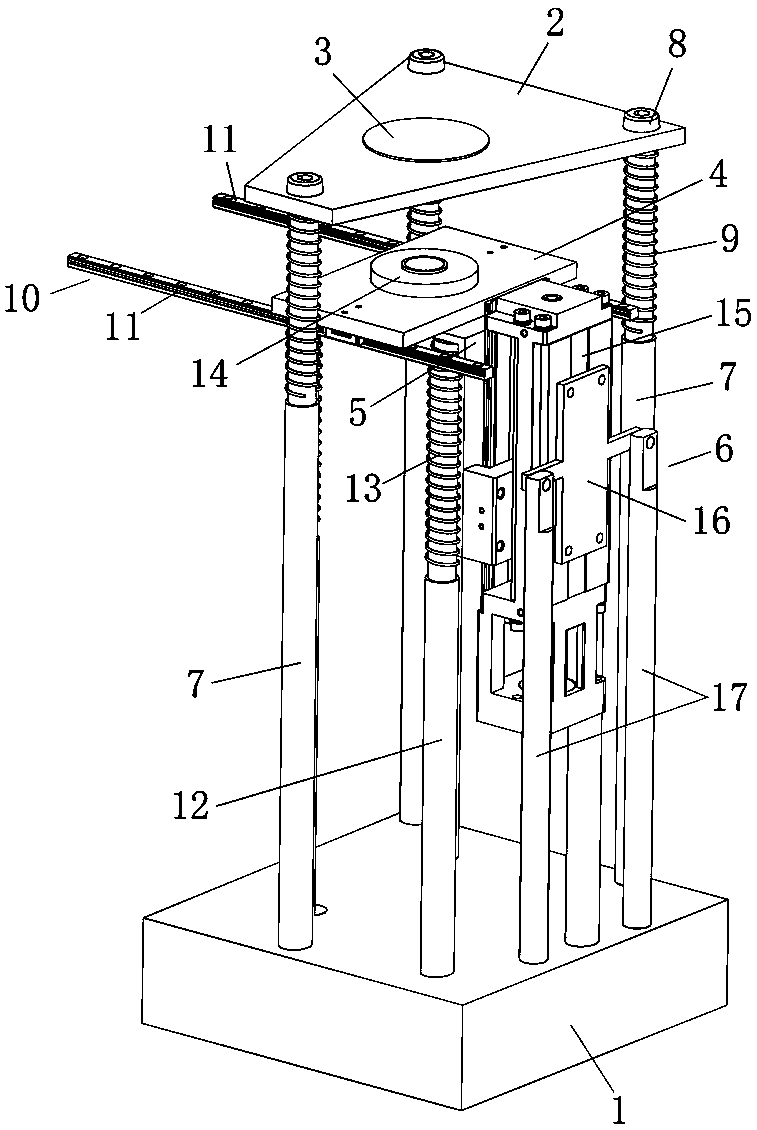

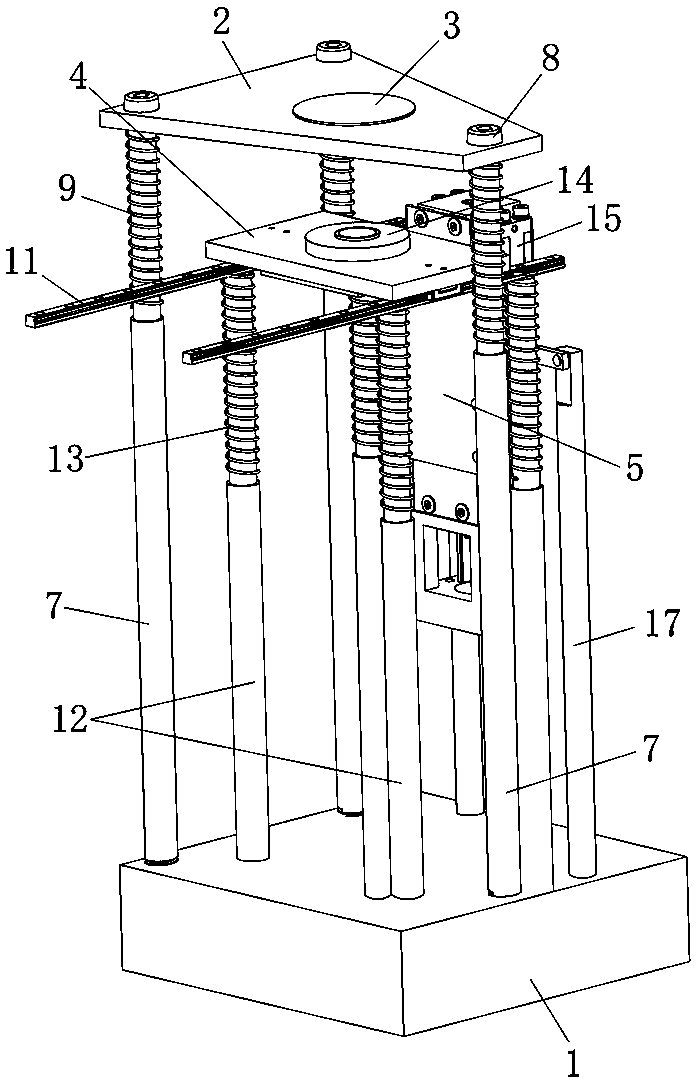

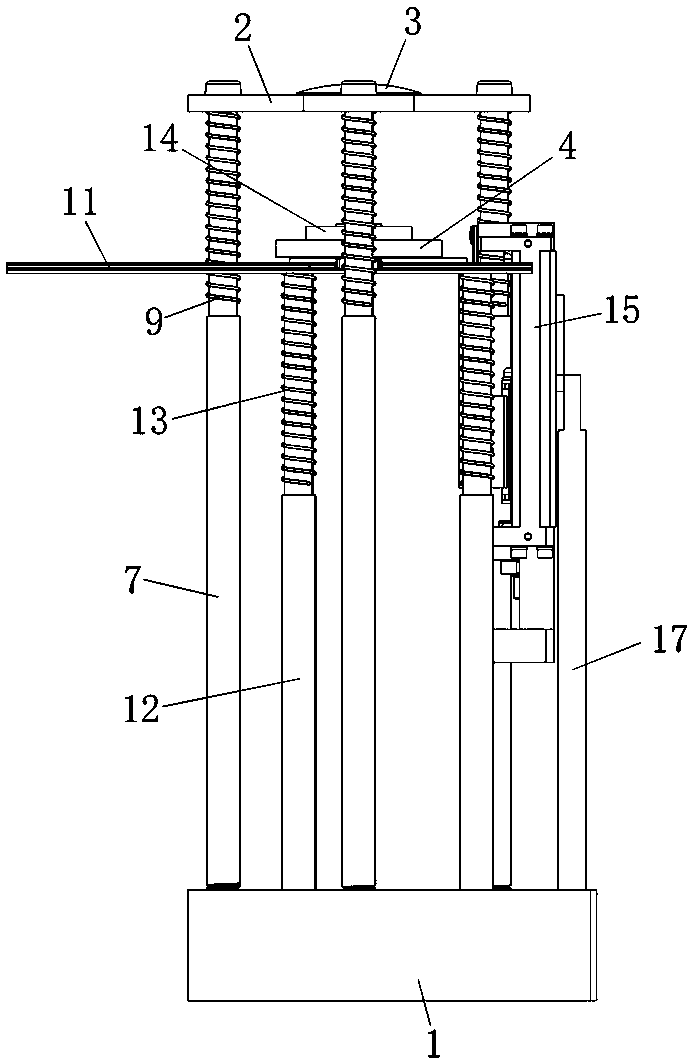

[0021] Such as Figure 1~4 As shown, a magnification image detector of the present invention includes a rectangular fixed workbench 1, and a magnifier base 2 for installing a magnifier 3 is fixed above the fixed workbench 1 via a support assembly. The bottom of the multiplier base 2 is provided with a lens base 4 for installing a lens, and the bottom of the lens base 4 is provided with a camera base 5 for installing a CMOS image sensor and driven up and down through a lifting mechanism 6, and the lifting mechanism 6 passes through the camera base. 5 Drive the CMOS image sensor to rise and fall vertically to adjust the back focus of the lens.

[0022] In this embodiment, the support assembly includes three support rods A7, and the three support rods A7 are distributed in a triangle. The lower ends of the support rods A7 are screwed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com