Aero-engine fuel combustion characteristic experiment detection system

An aero-engine and detection system technology, which is used in jet engine testing, gas turbine engine testing, color/spectral characteristic measurement, etc. Realistic, low-cost effects on ignition and combustion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

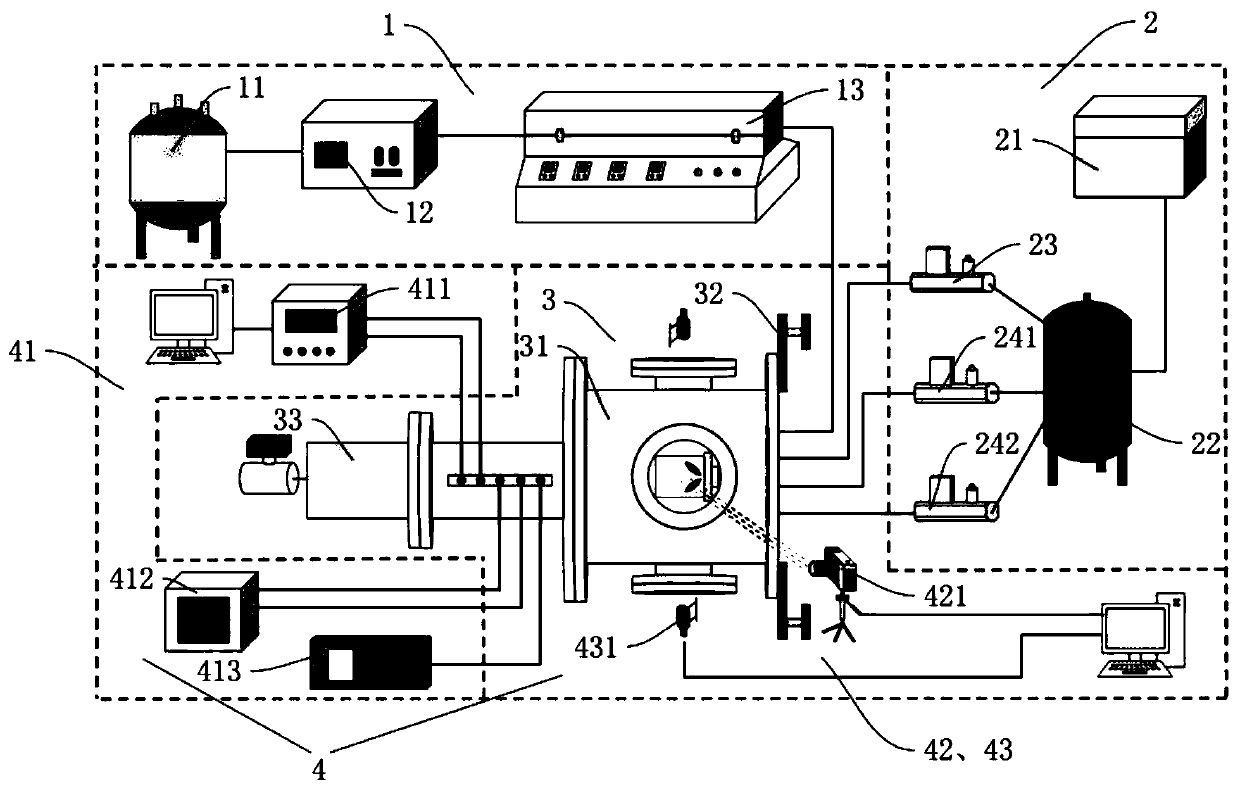

[0037] Such as figure 1 As shown, an aero-engine fuel combustion characteristic experimental detection system includes a fuel system 1, an air intake system 2, a combustion system 3, and a data sampling and detection system 4;

[0038] Fuel system 1 is used to provide controllable flow of vaporized fuel for combustion system 3;

[0039] Air intake system 2 is used to provide main combustion air and cooling air for combustion system 3;

[0040] The combustion system 3 is used to provide a confined space with controllable combustion pressure for the combustion of fuel oil;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com