Drilling fluid comprehensive performance automatic detection system

A comprehensive performance and automatic detection technology, which is applied in the direction of analyzing materials and instruments, can solve the problems of manpower consumption and low degree of automation, and achieve the effect of improving cleaning strength and rapid cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

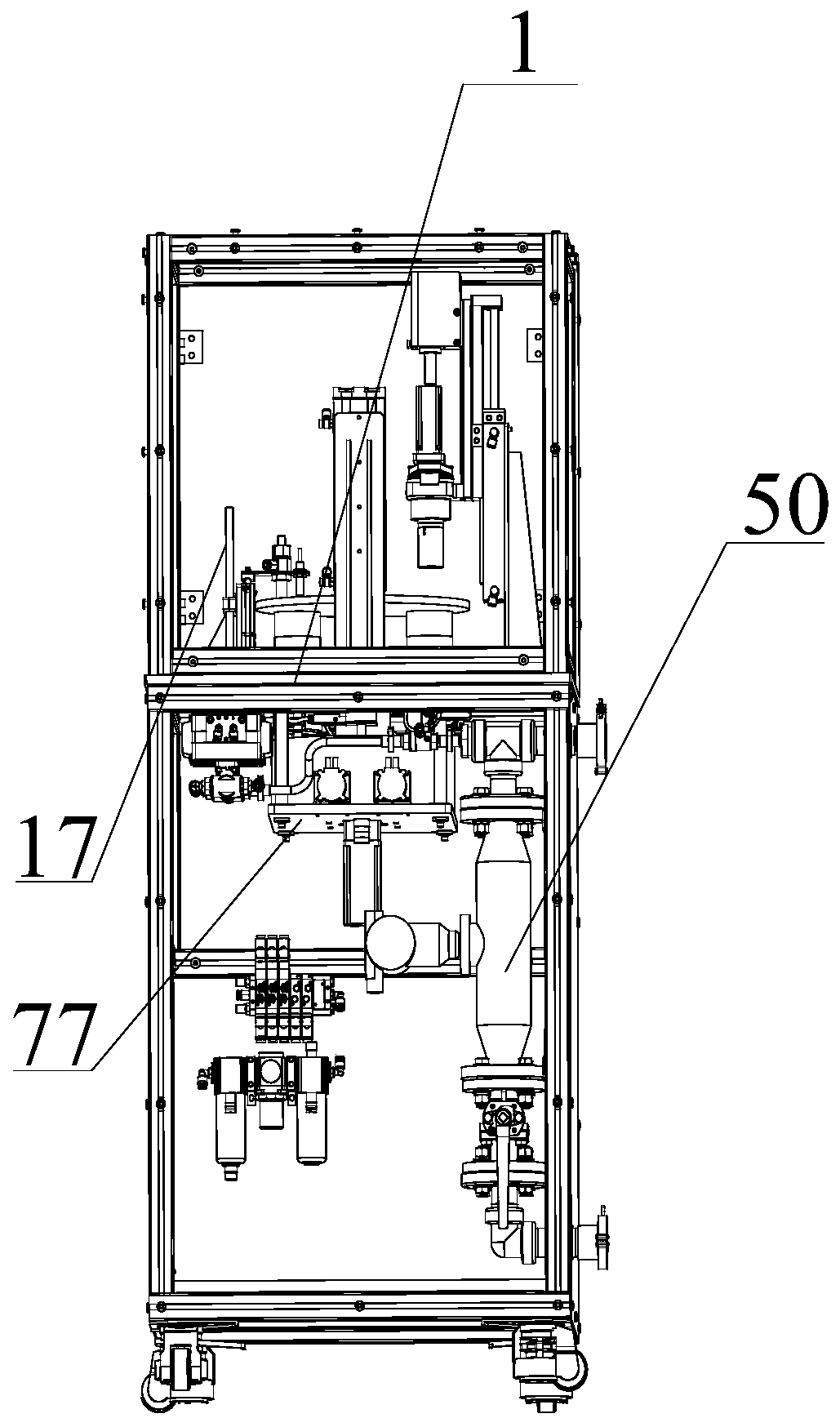

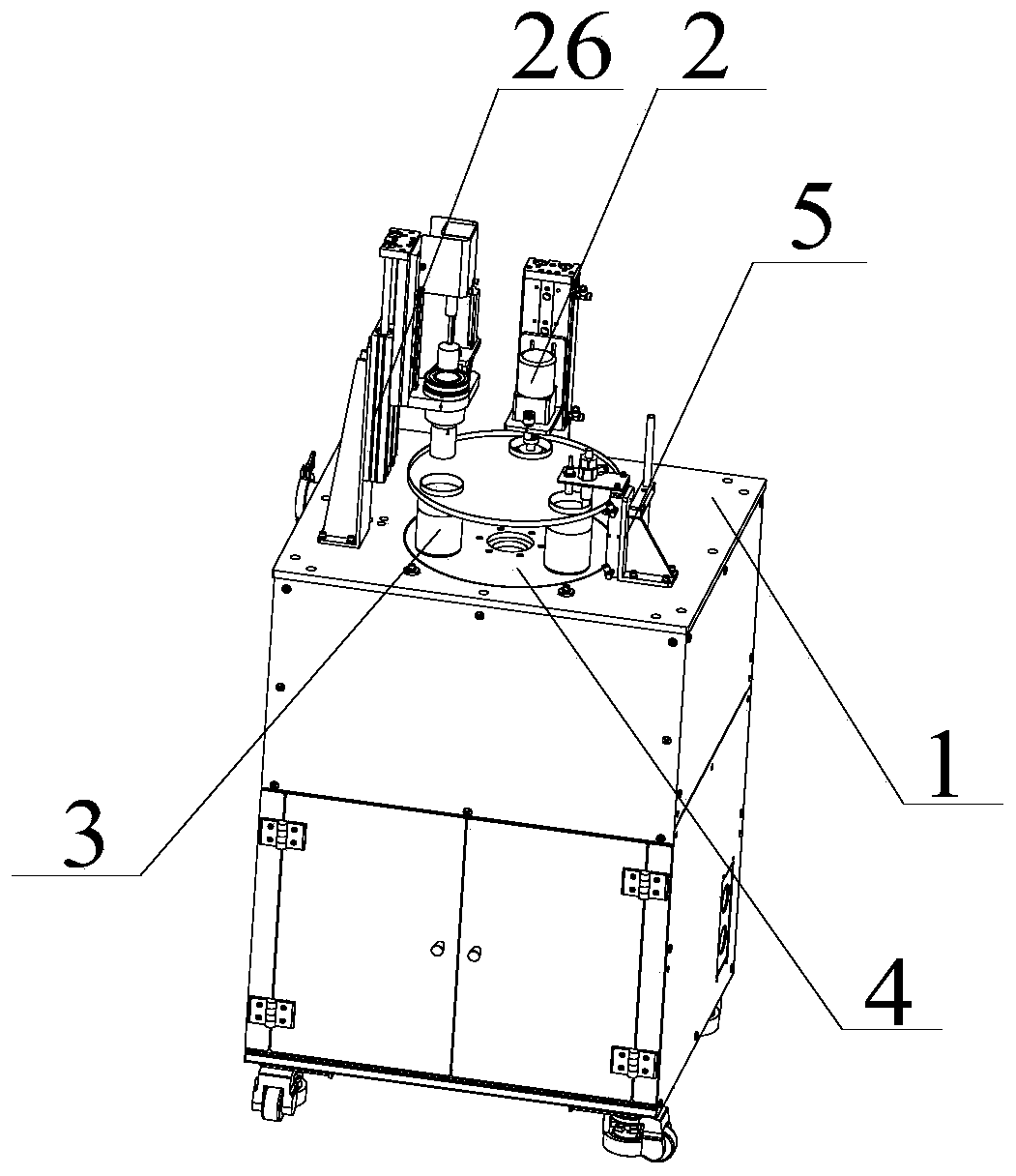

[0078] Such as Figures 1 to 26 The comprehensive performance automatic detection system of drilling fluid shown includes viscosity measurement system and water analysis system;

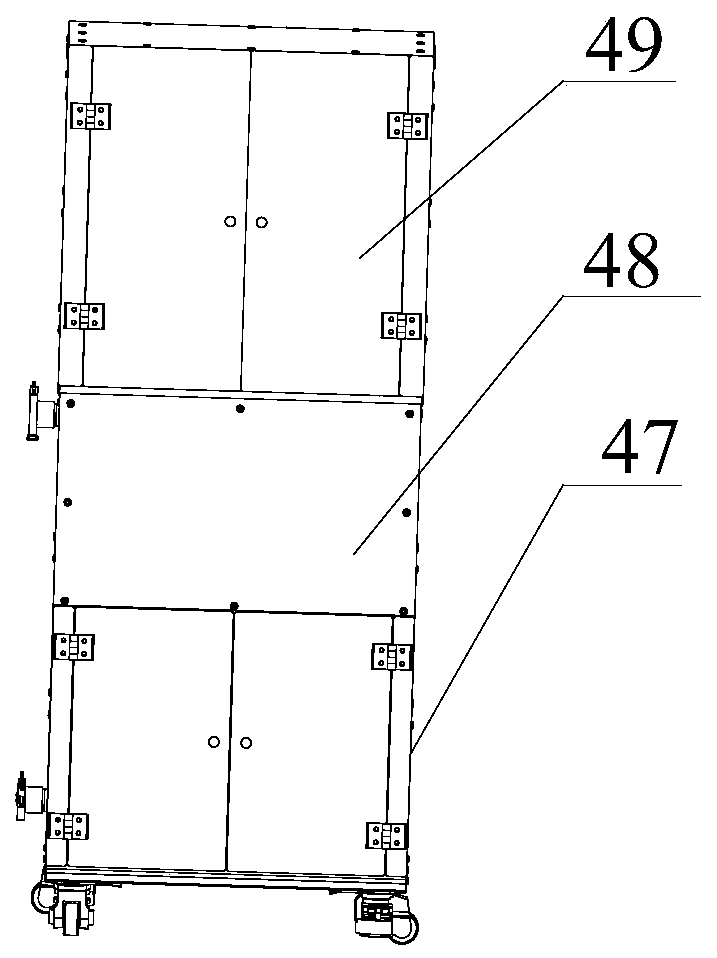

[0079] The viscosity measurement system includes a cabinet, the cabinet includes a lower layer 47, a middle layer 48, and an upper layer 49, the lower layer 47 is provided with a waste liquid bucket 51, and the middle layer 48 is provided with an effusion tank 85, and the effusion tank 85 and the waste liquid bucket 51 pass through the water pipe connection, the upper layer 49 is provided with a workbench 1, and the top of the workbench 1 is provided with a movable disk 4, a grouting assembly 5, a cleaning assembly 2 and a measuring assembly 26, and the movable disk 4 can surround the center of circle of the movable disk 4 on the workbench 1 Rotate, movable plate 4 is provided with some paddle cups 3, and the bottom of paddle cup 3 is all provided with connecting pipe 79, and one end of connecting pi...

Embodiment 2

[0082] Drilling fluid comprehensive performance automatic detection system, on the basis of embodiment 1, in the viscosity measurement system:

[0083] The grouting assembly 5 also includes a first support frame 8 and a cross plate 16, the first support frame 8 is fixed on the top of the workbench 1, the first drive mechanism 9 is fixed on the side wall of the first support frame 8, the cross plate 16 and the first support frame The output end of a driving mechanism 9 is connected, and a connecting sleeve 12 is provided on the horizontal plate 16, and the connecting sleeve 12 runs through the horizontal plate 13. A connecting rod 11 is arranged in the connecting sleeve 12, and a through hole is provided on the connecting rod 11, and the conduit 10 is inserted In the through hole, and the conduit 10 is matched with the through hole gap; the side wall of the connecting sleeve 12 is provided with a connector 15, the connector 15 communicates with the through hole, and the connecto...

Embodiment 3

[0087] Drilling fluid comprehensive performance automatic detection system, on the basis of embodiment 2, in the viscosity measurement system:

[0088] The correction box 35 is provided with a connecting block 38, which can move on the moving plate 34, and the connecting block 38 is provided with a protruding block 43. The protruding block 43 is provided with a mounting sleeve 44, and the mounting sleeve 44 is provided with a first spring. 42 , the first spring 42 is provided with two pressing sleeves 46 , one of which is connected to the torque detector 41 , and the other pressing sleeve 46 is provided with an adjusting nut 45 , and the torque detector 41 is connected to the rotor 11 . The side wall of the fourth driving mechanism 39 is also provided with two second slide tables 40, and the moving plate 34 is provided with two second slide grooves matched with the second slide table 40, and the second slide table 40 is positioned at the second slide table 40. In the groove; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com