Method for improving absorption of traditional tobacco leaf atomizing agent

A technology of atomizing agent and tobacco leaves, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of low work efficiency, poor effect of atomizing agent addition, and slow immersion process, so as to retain the remaining amount, avoid complicated procedures, and accelerate absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

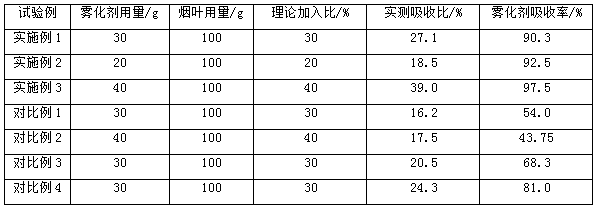

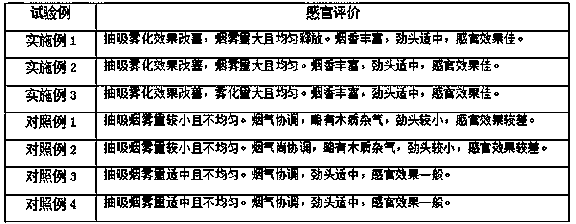

Examples

Embodiment 1

[0027] A method for improving the absorption of traditional tobacco leaf aerosol, comprising the following steps:

[0028] (1) Preparation of an atomizer for cigarettes: According to parts by mass, 1 part of glycerin, 10 parts of propylene glycol, 20 parts of dipropylene glycol, and 3 parts of sorbitol were mixed to prepare an atomizer for cigarettes.

[0029] (2) Weigh 30g of the tobacco atomizer prepared in step (1) and quickly spray it on the surface of 100g of uniformly mixed formula tobacco leaves, and then ultrasonically treat it for 28min at 3°C, with an ultrasonic power of 150W and an ultrasonic frequency of 25KHz. , Accelerate the absorption of aerosol by tobacco leaves.

[0030] (3) Send the tobacco leaves obtained by ultrasonication in step (2) into a closed container, and inject CO into the container 2 Pressurize to 31kg / cm 3 . Then filled with liquid CO 2 , so that the tobacco leaves are completely immersed in liquid CO 2 In, soak for 4min. Then open the val...

Embodiment 2

[0033] A method for improving the absorption of traditional tobacco leaf aerosol, comprising the following steps:

[0034] (1) Preparation of an atomizer for cigarettes: According to parts by mass, 1 part of glycerin, 5 parts of propylene glycol, 15 parts of dipropylene glycol, and 2 parts of sorbitol were mixed to prepare an atomizer for cigarettes.

[0035] (2) Weigh 20g of the tobacco atomizer prepared in step (1) and quickly spray it on the surface of 100g of uniformly mixed formula tobacco leaves, and then ultrasonically treat it for 15min at 0°C, with an ultrasonic power of 400W and an ultrasonic frequency of 20KHz. , Accelerate the absorption of aerosol by tobacco leaves.

[0036] (3) Send the tobacco leaves obtained by ultrasonication in step (2) into a closed container, and inject CO into the container 2 Pressurize to 30kg / cm 3 . Then filled with liquid CO 2 , so that the tobacco leaves are completely immersed in liquid CO 2 In, soak for 2min. Then open the valv...

Embodiment 3

[0039] A method for improving the absorption of traditional tobacco leaf aerosol, comprising the following steps:

[0040] (1) Preparation of an atomizer for cigarettes: According to parts by mass, 1 part of glycerin, 20 parts of propylene glycol, 50 parts of dipropylene glycol, and 10 parts of sorbitol were mixed to prepare an atomizer for cigarettes.

[0041] (2) Weigh 40g of the tobacco atomizer prepared in step (1) and quickly spray it on the surface of 100g of uniformly mixed formula tobacco leaves, and then ultrasonically treat it for 30min at 25°C, with an ultrasonic power of 1000W and an ultrasonic frequency of 30KHz. , to accelerate the absorption of aerosol by tobacco leaves

[0042] (3) Send the tobacco leaves obtained by ultrasonication in step (2) into a closed container, and inject CO into the container 2 Pressurize to 40kg / cm 3 . Then filled with liquid CO 2 , so that the tobacco leaves are completely immersed in liquid CO 2, the soaking time is 15min. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com