Method for ultrasonic welding of fabric

An ultrasonic welding and fabric technology, which is applied to the seams of textile materials, the cutting of textile materials, textiles and papermaking, etc., can solve the problems of prolapse and inconvenient operation, and achieve the convenience of starting the next time, reduce the difficulty of processing, and save labor resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

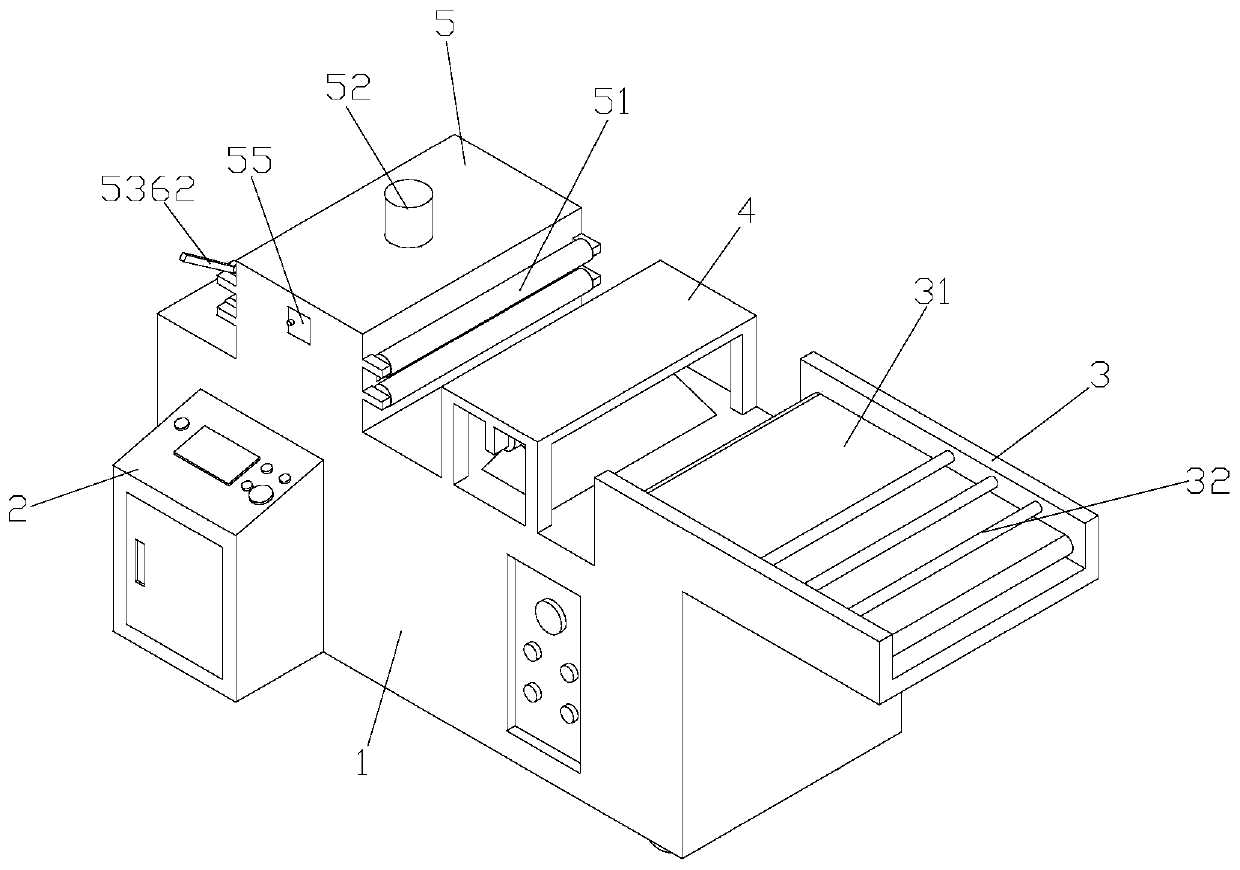

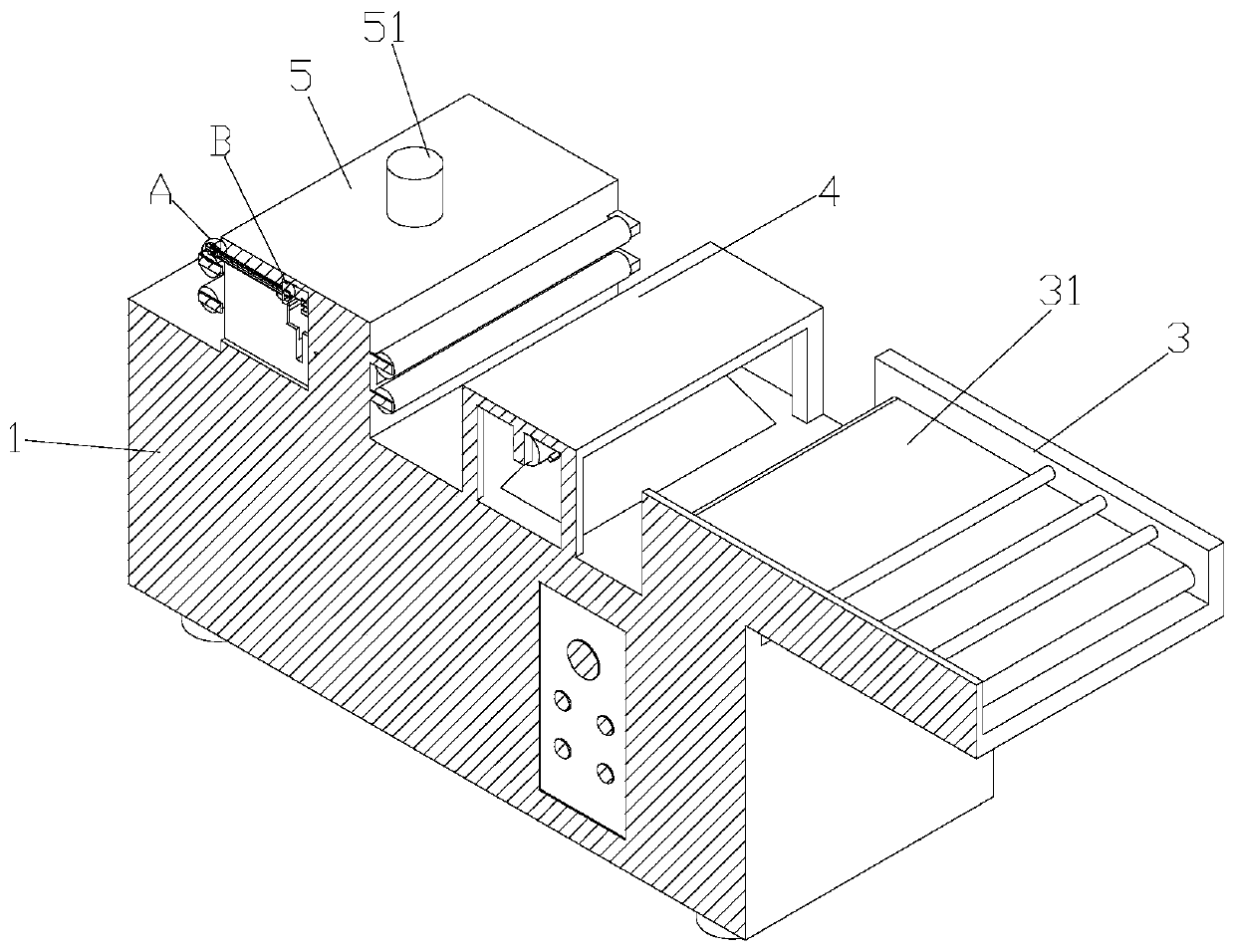

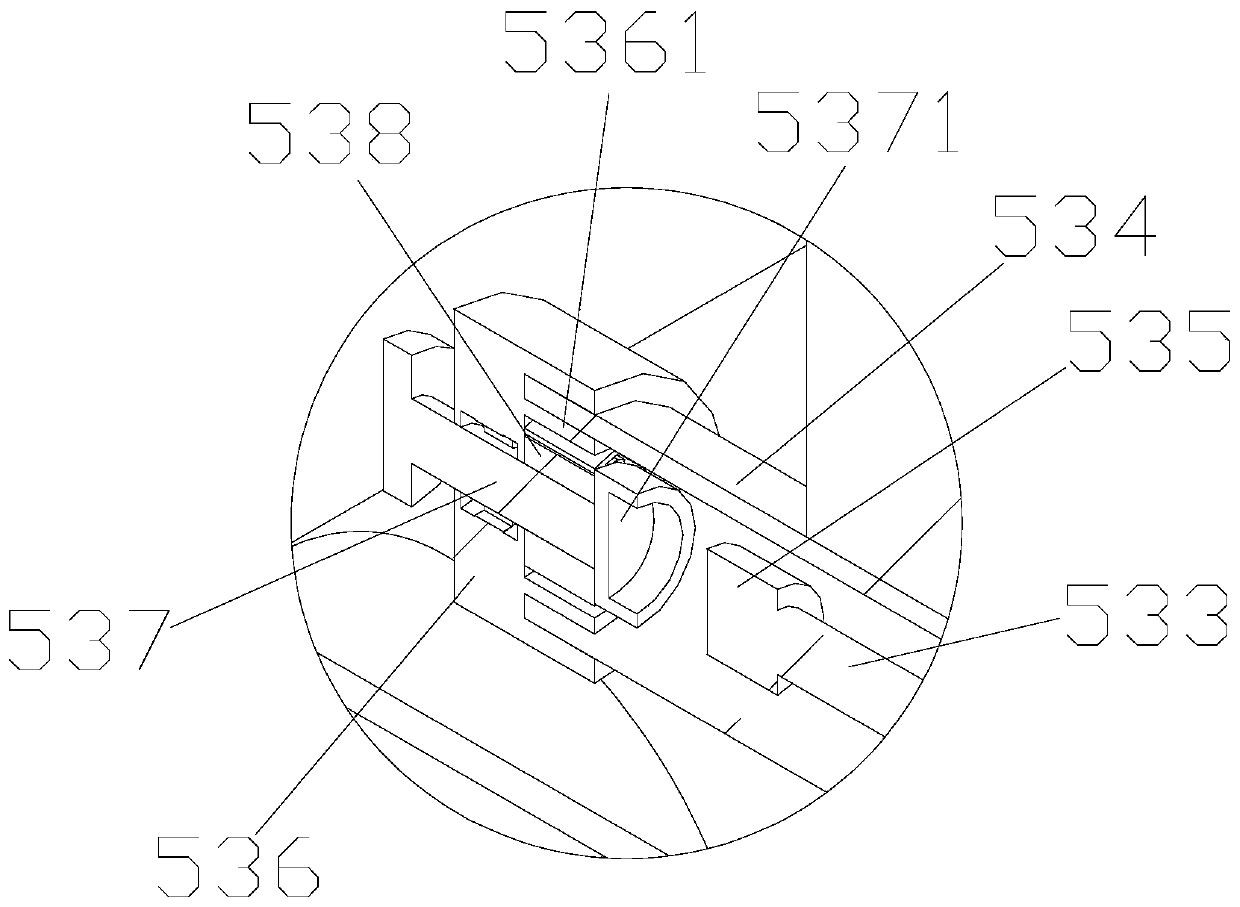

[0029] Such as Figure 1-12 Shown, a kind of ultrasonic welding method of fabric, described fabric comprises top layer, interlayer and bottom layer, the ultrasonic welding method of described fabric comprises: a, top layer, interlayer and bottom layer are cut into required width respectively, top layer after cutting , the interlayer and the bottom layer are placed on the fixed wheels respectively; b. Pull out one end of the top layer, the interlayer and the bottom layer respectively, so that the top layer, the interlayer and the bottom layer are stacked together at a certain distance in order from top to bottom, and the stacked The fabric is put into the ultrasonic welding machine, and the part of the overlapped edge is welded to form a product; the certain distance is 10cm or less; the thickness of the welded seam area is equal to that of the main body of the fabric Thickness; the fabric is a plain weave or a fabric made by helically winding fabric strips of woven yarn materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com