A Closed-loop Aircraft Fuel Tank Airborne Inerting System

A fuel tank and closed-loop technology, which is applied in the aviation field, can solve the problems of large compensation loss of aircraft, low efficiency of separation membrane, and unusability, etc., and achieve the effects of small system weight and size, intelligent system operation, and realization of mode switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

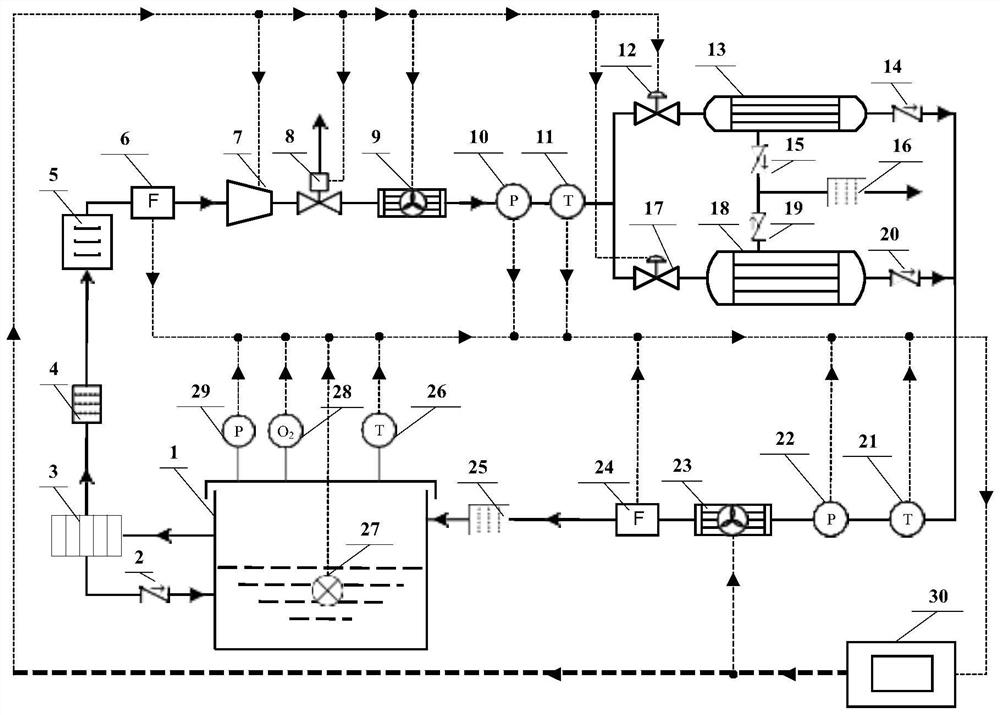

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that in the description of the present invention, the terms "first", "second", and "third" are only used for descriptive purposes and cannot be understood. To indicate or imply relative importance.

[0031] Such as figure 1 As shown, a closed-loop aircraft fuel tank airborne inertization system includes a fuel tank 1, the gas outlet of the fuel tank 1 is connected to the inlet of the condenser 3 through a pipeline, and the gas outlet of the condenser 3 is connected to the first flame arrester 4 through the pipeline in turn, and the gas drying Device 5, first flow sensor 6, gas compressor 7, electric pressure regulating valve 8 gas inlet.

[0032] The pressure relief port of the electric pressure regulating valve 8 is connected to the outside of the machine through a pipeline.

[0033] The gas outlet of the electric pressure regulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com