Temperature-controllable fuel tank inerting device based on catalytic combustion technology

A catalytic combustion and fuel tank technology, applied in the field of aviation systems, can solve the problems of uneven temperature of the catalytic reactor, difficult to control the outlet temperature, large preheating capacity, etc., and achieves simple structure, controllable temperature, and less preheating gas amount. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

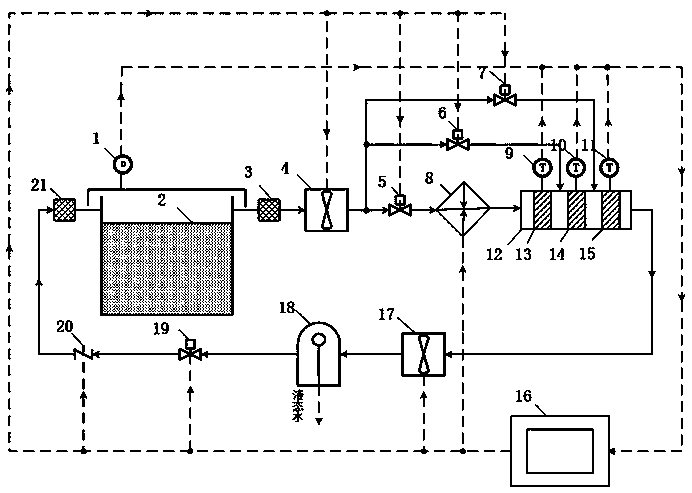

[0021] Embodiments of the present invention provide a temperature-controllable fuel tank inerting device based on catalytic combustion technology, such as figure 1 As shown, it includes: oxygen concentration sensor 1, first flame arrester 3, output fan 4, first electric control valve 5, second electric control valve 6, third electric control valve 7, heater 8, first temperature sensor 9 , the second temperature sensor 10, the third temperature sensor 11, the reactor 12, the first catalytic bed 13, the second catalytic bed 14, the third catalytic bed 15, the controller 16, the input fan 17, the water separator 18, the fourth Electric control valve 19, check valve 20, second flame arrester 21.

[0022] The probe of the oxygen concentration sensor 1 ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com