Garbage can pressing ring and garbage can

A trash can, all-in-one technology, applied in the direction of trash cans, garbage collection, household appliances, etc., can solve the problems of inconvenient general design and mass production, garbage bags are easy to dirty hands, need to be cleaned frequently, etc. The effect of mass production, easy production and processing, easy disassembly and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

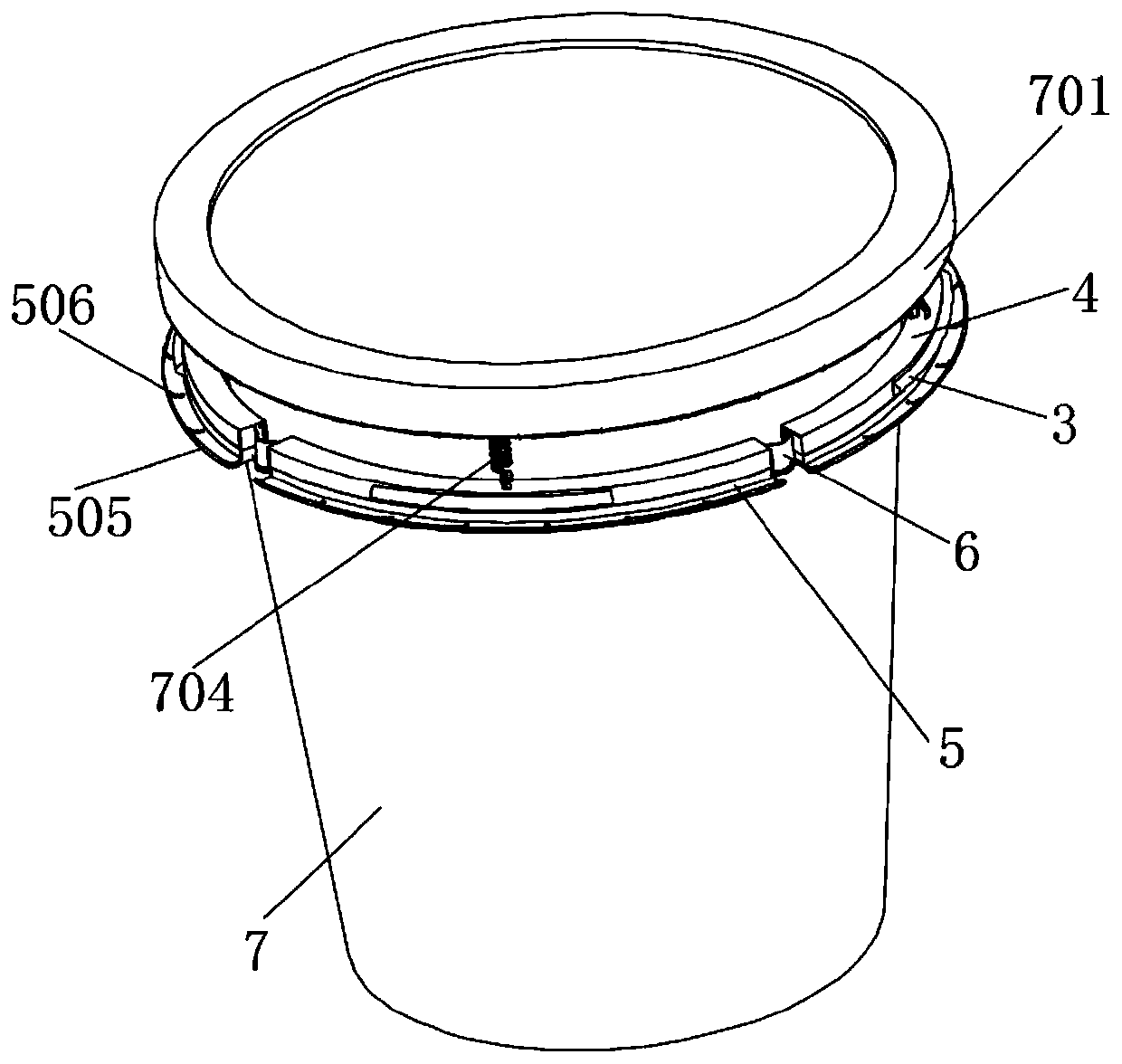

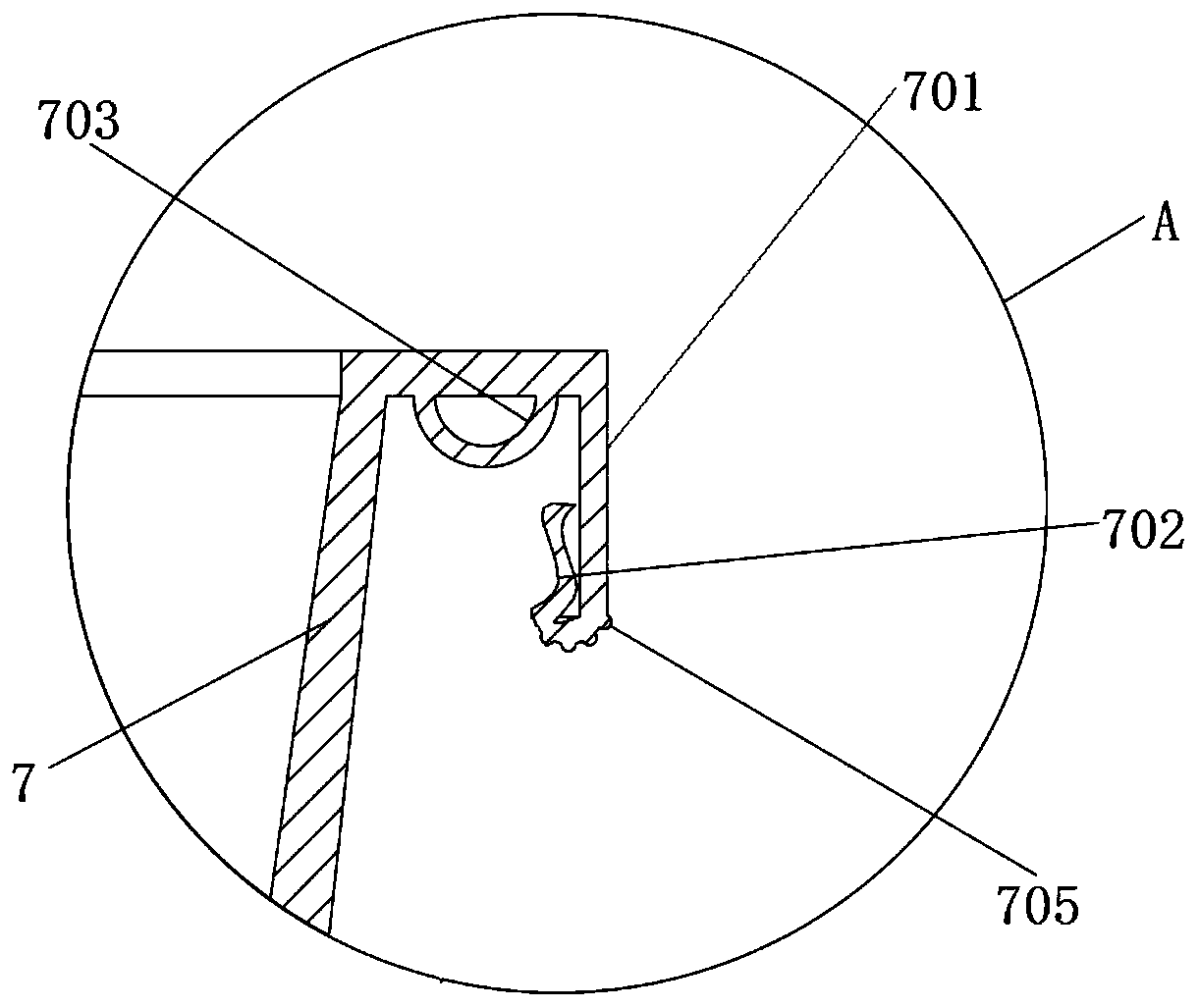

[0045] see Figure 4-10 As shown, the present invention is a garbage can hold-down ring, including a hold-down ring assembly 1; the hold-down ring assembly 1 includes two or more hold-down ring members 2; at least any two hold-down ring members 2 are provided with an engaging portion 3;

[0046] Among them, such as figure 1As shown, the pressure ring member 2 includes an upper pressure ring 4 and a lower pressure ring 5; the upper pressure ring 4 is clamped or threadedly connected to the lower pressure ring 5, which can be produced separately, which is convenient for manufacturing and processing, and is also convenient for disassembly;

[0047] Two adjacent pressure ring members 2 are connected by elastic connectors 6, and the number of pressure ring members 2 and elastic connectors 6 can be increased or decreased according to the diameter of the barrel body 7, which can be suitable for barrel bodies 7 of different types and different diameters; and When the quantity of the p...

Embodiment 2

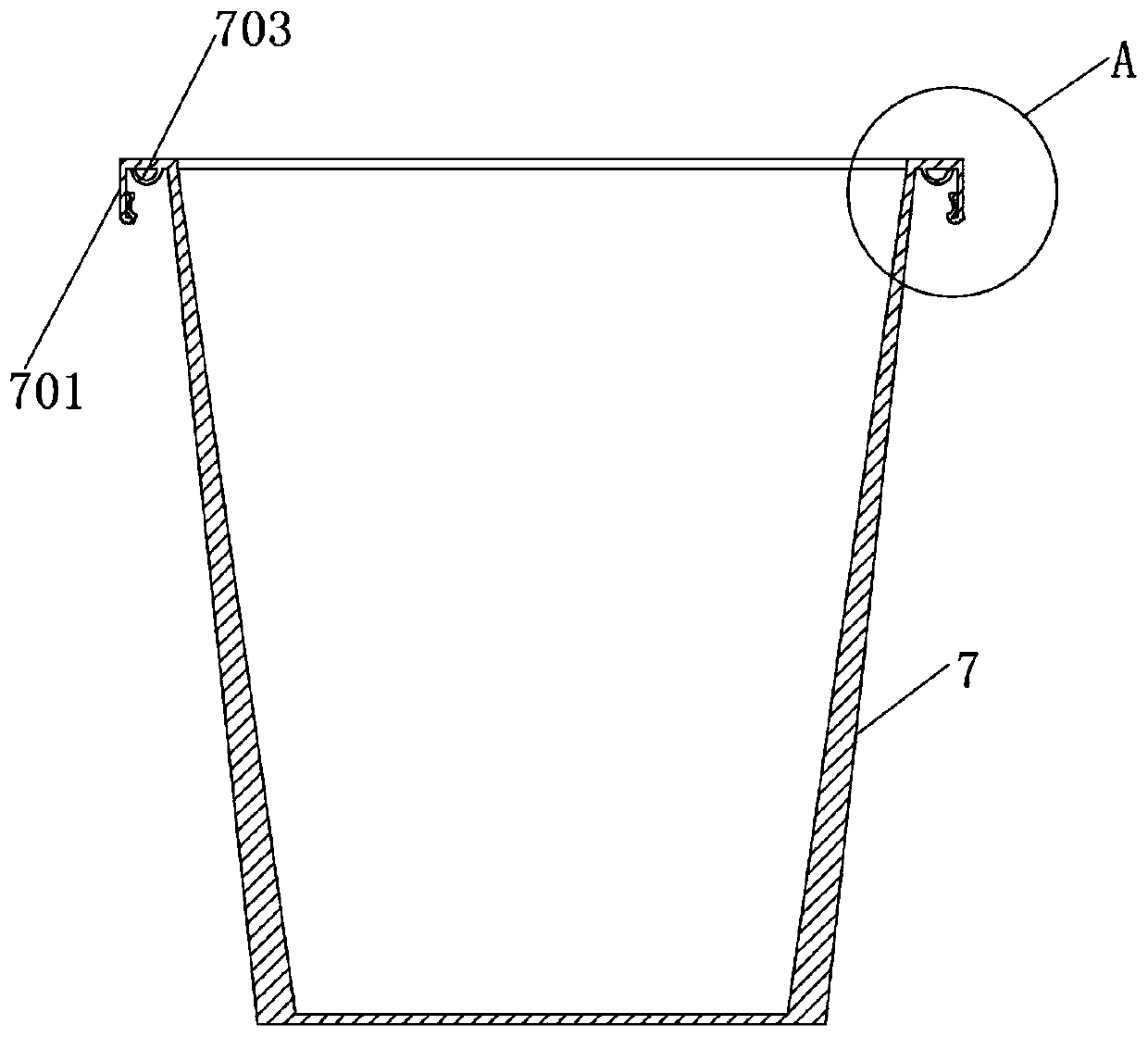

[0056] see Figure 1-10 As shown, the present invention is a kind of trash can, comprising a pressure ring assembly 1 and a bucket body 7 with an opening matched with the pressure ring assembly 1; the pressure ring assembly 1 includes two or more pressure ring members 2; at least any two The clamping member 2 is provided with an engaging portion 3;

[0057] Among them, such as figure 1 As shown, the pressure ring member 2 includes an upper pressure ring 4 and a lower pressure ring 5; the upper pressure ring 4 is clamped or threadedly connected to the lower pressure ring 5, which can be produced separately, which is convenient for manufacturing and processing, and is also convenient for disassembly;

[0058] Two adjacent pressure ring members 2 are connected by elastic connectors 6, and the number of pressure ring members 2 and elastic connectors 6 can be increased or decreased according to the diameter of the barrel body 7, which can be suitable for barrel bodies 7 of differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com