Automatic cable conveying and straightening device

A straightening device and straightening technology are applied in the directions of transportation and packaging, transportation of filamentous materials, thin material processing, etc., which can solve the problems of inability to solve the cable center line, unchanged, and low processing efficiency of the straightening technology. Achieve the effect of preventing sagging, high efficiency and high straightening accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

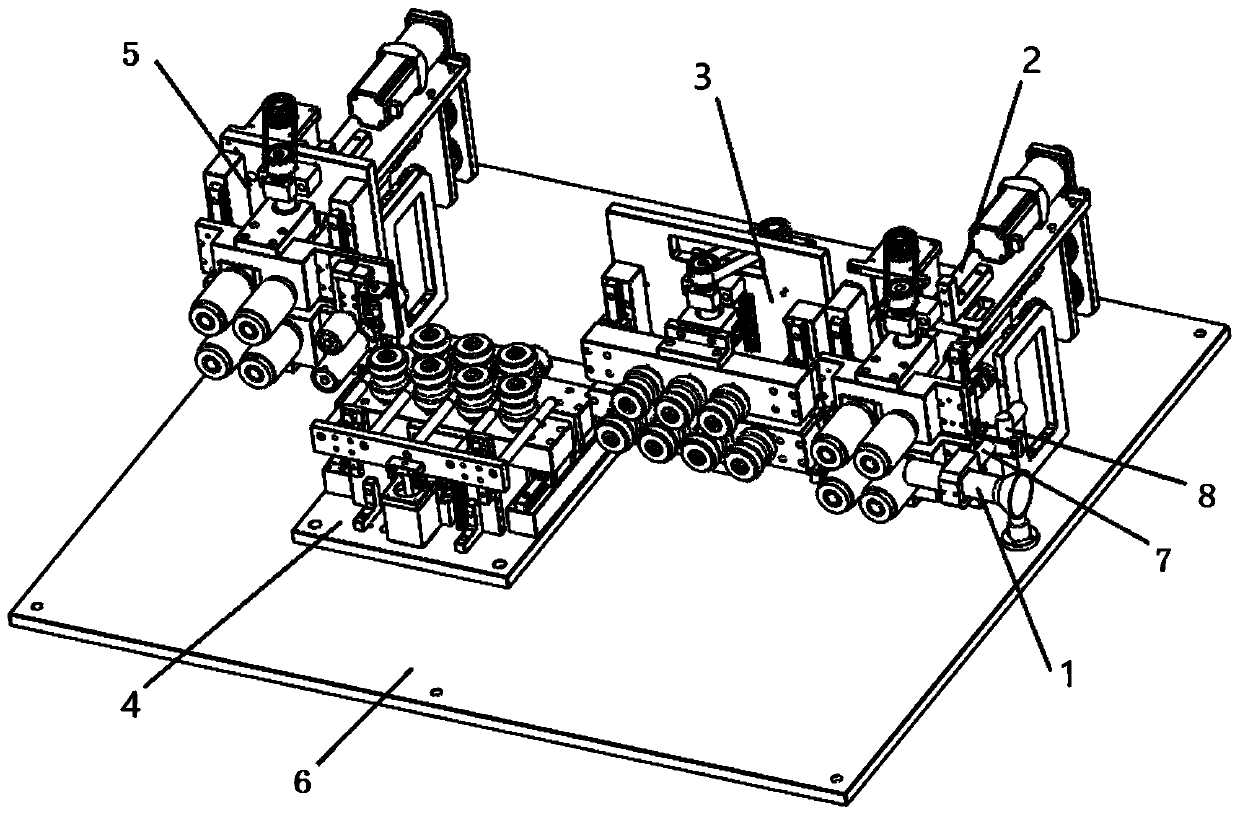

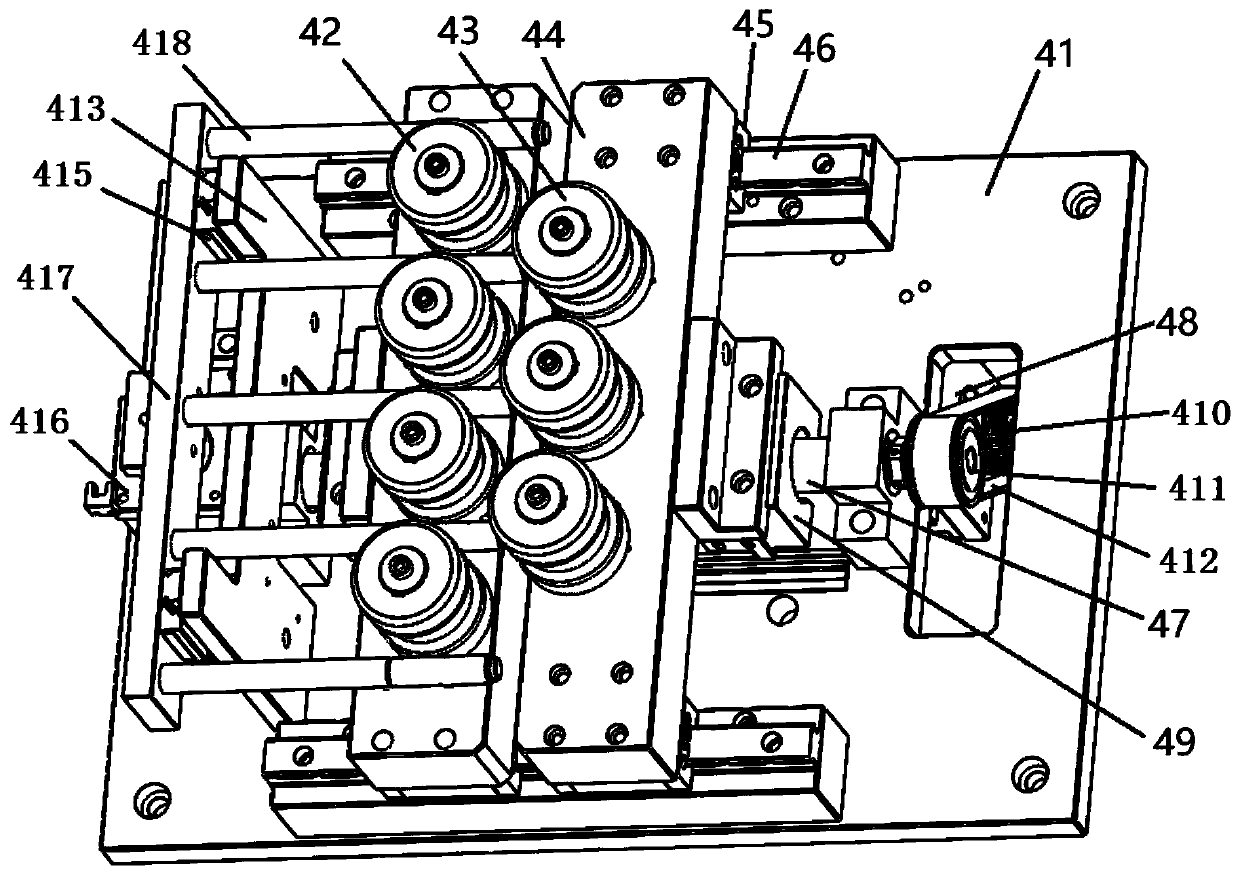

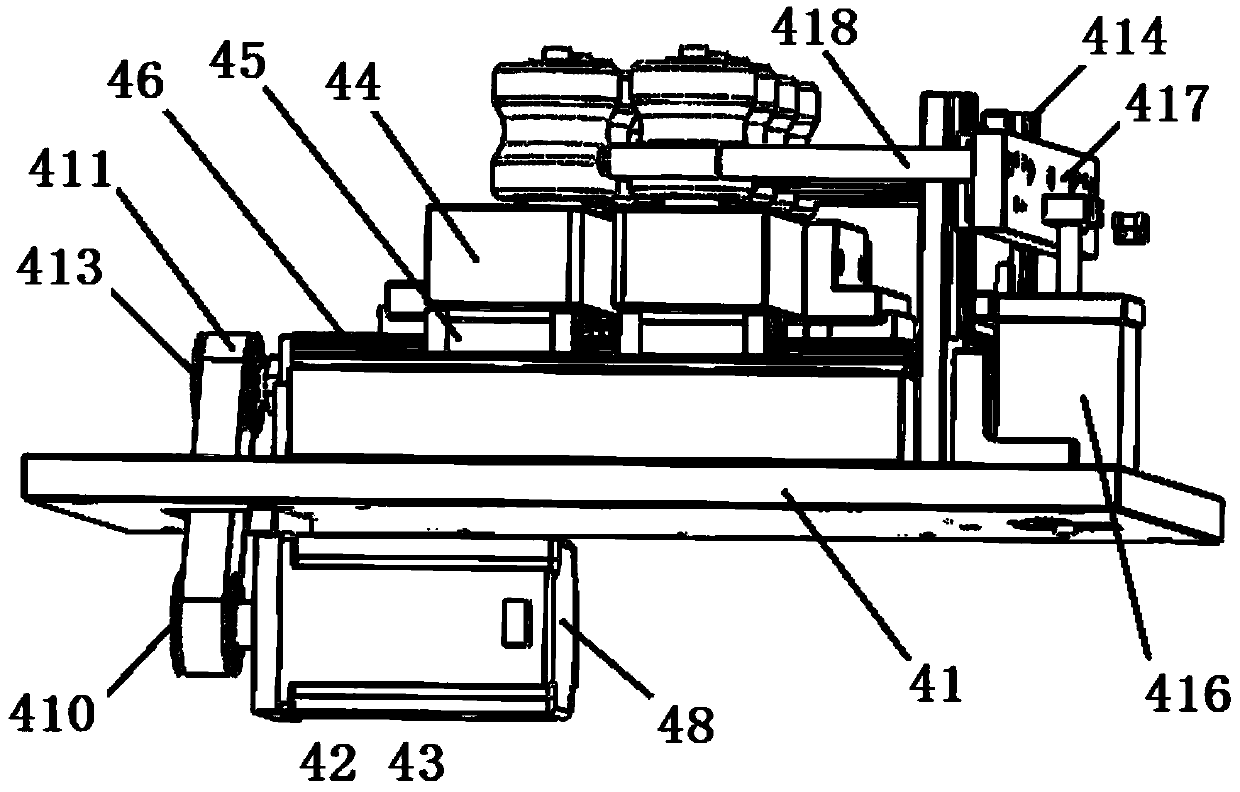

[0030] Such as Figure 1~5 As shown, a cable automatic line straightening device includes a workbench 6, an entrance guide device, two sets of wire feeders and two sets of straighteners, and the wire feeders include entrance wire feeders 2 with completely identical structures. And outlet wire feeder 5, described straightener comprises completely consistent but mutually vertical horizontal straightener 3 and vertical straightener 4 of structure, entrance guide device, entrance wire feeder 2, horizontal straightener 3, vertical straightener The straightener 4 and the outlet wire feeder 5 are fixed on the workbench 6 sequentially from front to back, and the cables pass through the inlet guide device, the inlet wire feeder 2, the horizontal straightener 3, and the vertical straightener 4 in turn. Stretch out in the export wire device 5. The cable is guided by the entrance gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com