Yarn pressing plate

A yarn pressing board and raw material technology, applied in the direction of single-component polyester rayon, coating, fiber chemical characteristics, etc., can solve the problems of uncomfortable cloth wearing, poor performance in preventing non-penetrating damage, etc., and achieve excellent Effects of health care function, wide application prospect, excellent three-dimensional curl performance and warmth retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] A yarn pressing plate is made of stainless steel.

[0109] A gauze-pressing plate is shaped like a cuboid, wherein the length is about 2.5-3.5 meters, the width is 2-20 centimeters, and the thickness is 0.1-2 centimeters. The preferred technical solution is that the length is about 3.5 meters, the width is 12 centimeters, and the thickness is 1 centimeter.

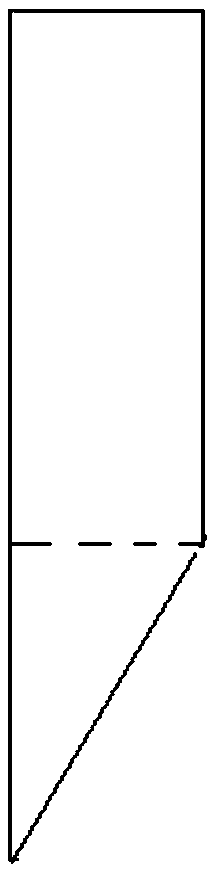

[0110] The utility model relates to a gauze-pressing plate whose cross section is a combination of a rectangle and a triangle, and the broad side of the rectangle coincides with one side of the triangle.

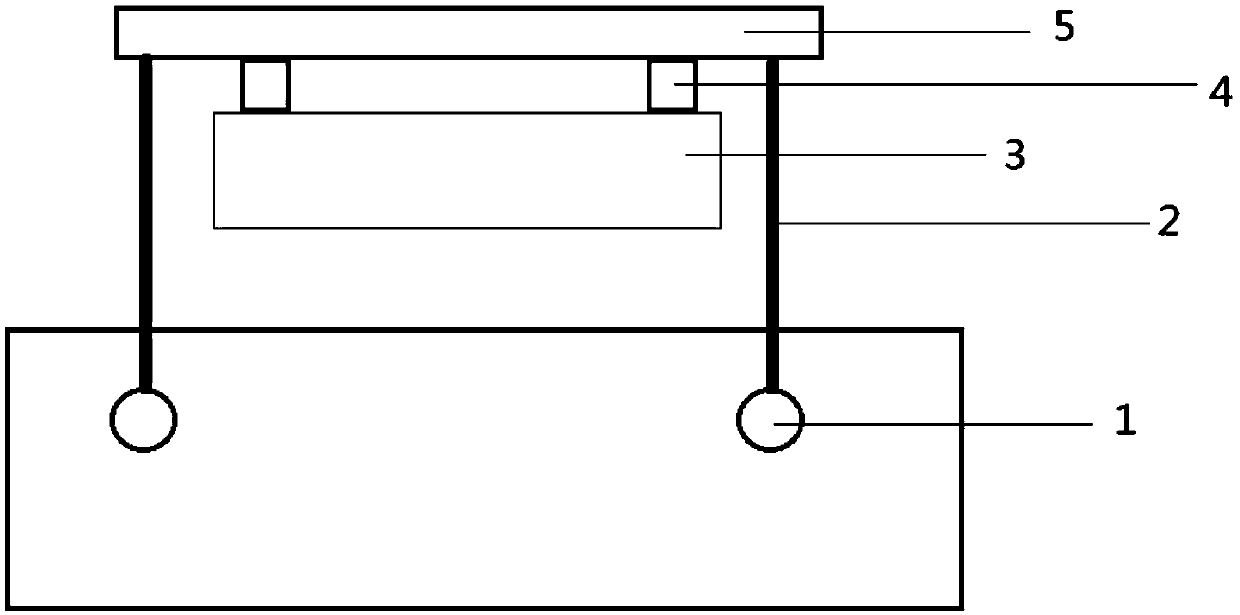

[0111] The yarn pressing plate 3 is connected with the main shaft 5 through the swing arm 4, and the crankshaft 1 of the warp knitting machine is connected with the main shaft 5 through the connecting rod 2; such as figure 1 shown.

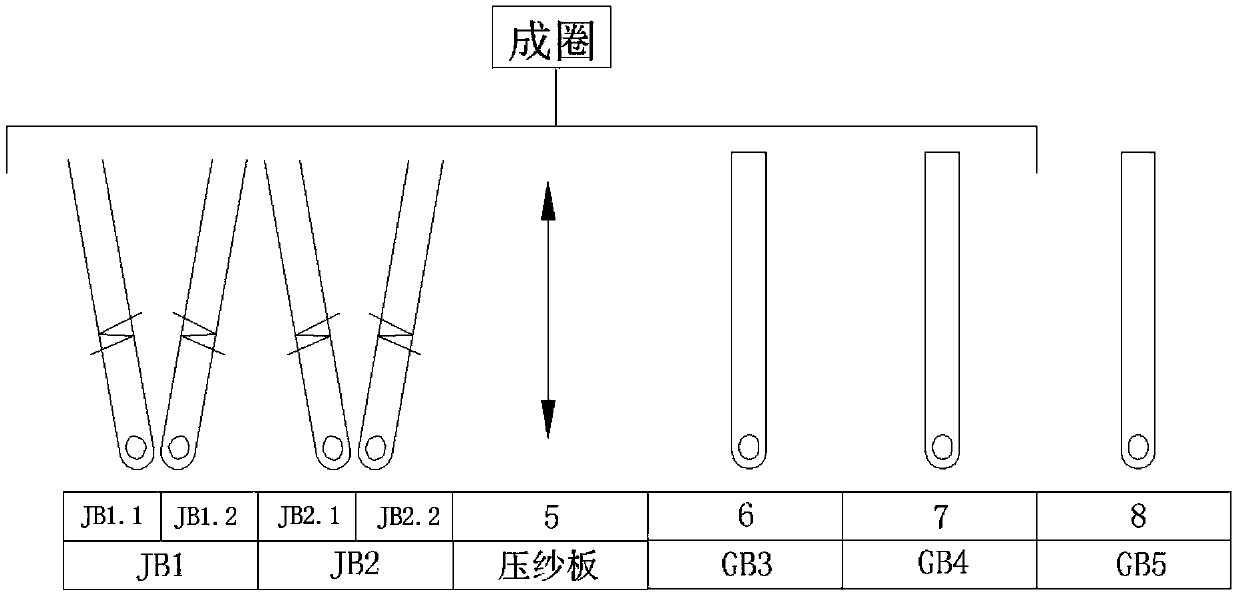

[0112] The yarn pressing plate is set at the middle position of the bar, and for a seven-bar warp knitting machine, it is set at the position of the fifth bar; such as figure 2 sh...

Embodiment 2

[0176] A yarn pressing plate is made of stainless steel.

[0177] A gauze-pressing plate is shaped like a cuboid, wherein the length is about 2.5-3.5 meters, the width is 2-20 centimeters, and the thickness is 0.1-2 centimeters. The preferred technical solution is that the length is about 3.5 meters, the width is 12 centimeters, and the thickness is 1 centimeter.

[0178] The utility model relates to a gauze-pressing plate whose cross section is a combination of a rectangle and a triangle, and the broad side of the rectangle coincides with one side of the triangle.

[0179] The yarn pressing plate 3 is connected with the main shaft 5 through the swing arm 4, and the crankshaft 1 of the warp knitting machine is connected with the main shaft 5 through the connecting rod 2; such as figure 1 shown.

[0180] The yarn pressing plate is set at the middle position of the bar, and for a seven-bar warp knitting machine, it is set at the position of the fifth bar; such as figure 2 sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com